Electrical automation control box

A technology of electrical automation and control boxes, applied in the direction of program control, computer control, general control system, etc., can solve problems affecting construction efficiency and easy loosening, and achieve the effects of improving construction convenience, preventing loosening, and improving connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

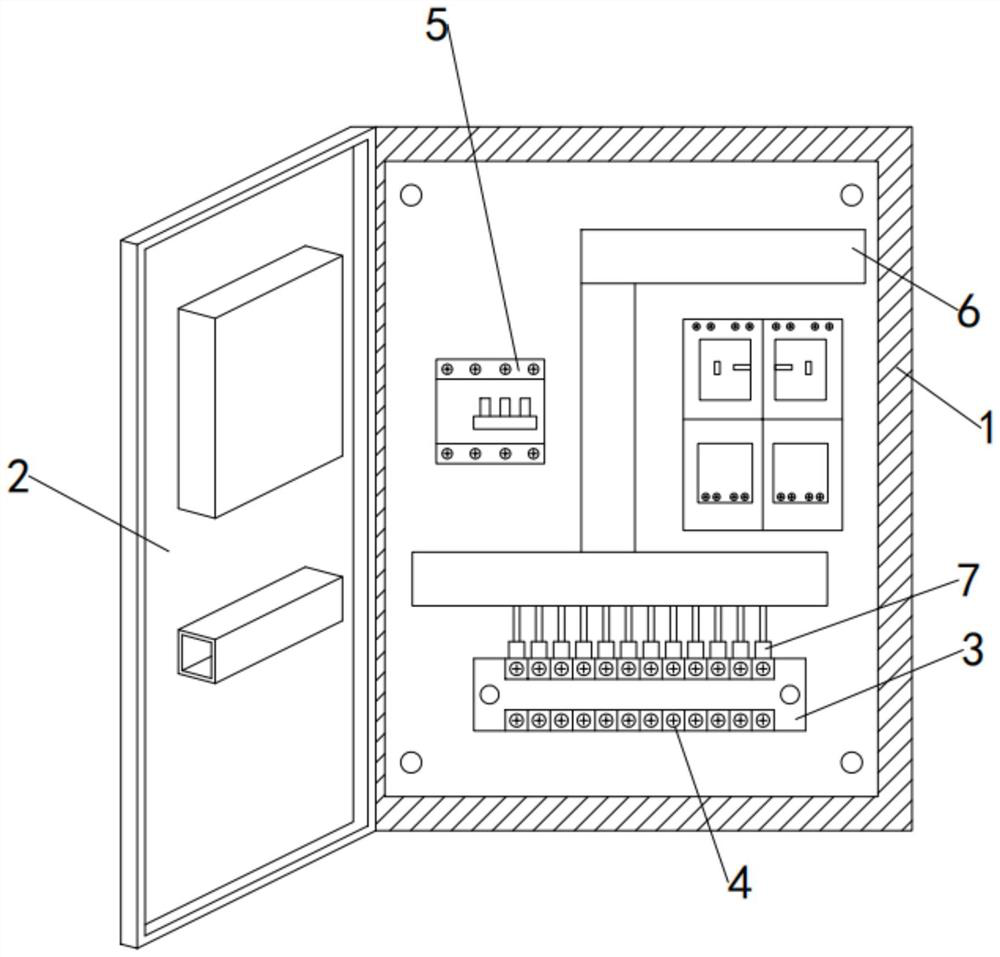

Embodiment 1

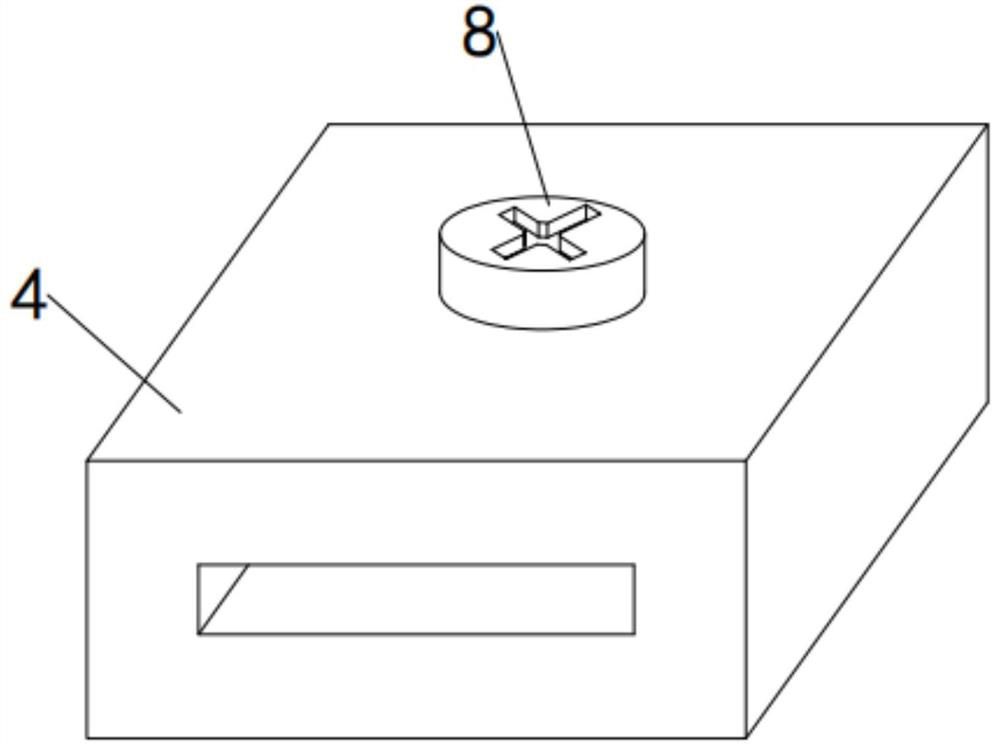

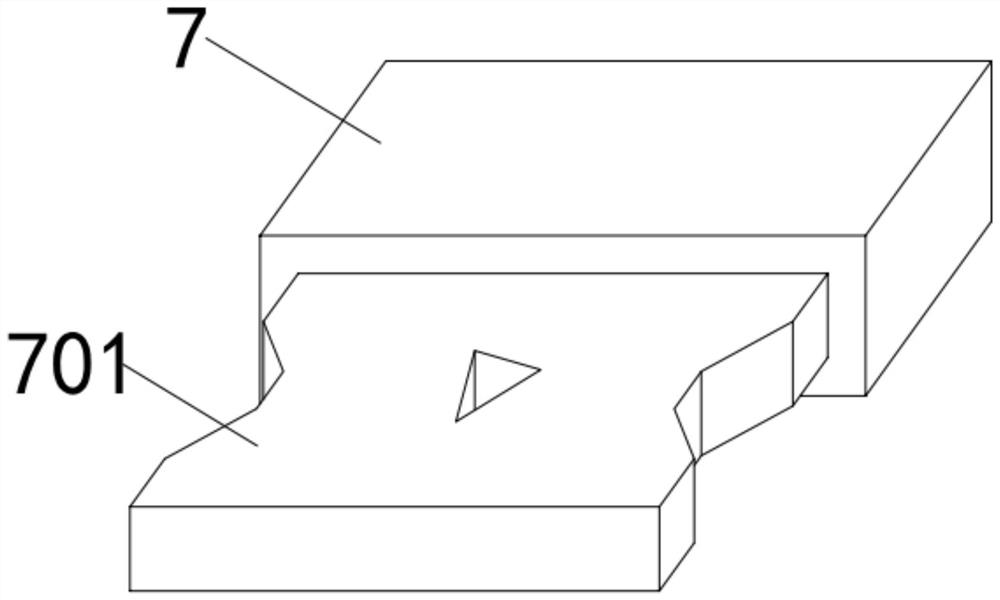

[0030] see Figure 1-4 , in the embodiment of the present invention, the front of the box body 1 is rotatably connected to the box body cover 2, and the inside of the box body 1 is arranged with a wiring board 3, an air switch 5 and a wire management tube 6 in sequence, and the upper and lower sides of the wiring board 3 are embedded and fixed with Terminal 4, and the front of terminal 4 is provided with a rectangular opening, and terminal 7 is embedded in terminal 4, and elastic cards 401 are embedded in the left and right sides of terminal 4, and the cross-section of elastic card 401 is trapezoidal. , the end of the wire end 7 is fixedly connected with an embedded block 701, and the embedded block 701 is arranged in a rectangular shape as a whole, and trapezoidal bayonets are opened on the left and right sides of the embedded block 701, that is, the embedded block 701 after the wire end 7 is connected to the terminal 4 The bayonets on the left and right sides will be locked ...

Embodiment 2

[0034] see Figure 5-7 , in this embodiment, the top of the locking screw 8 is fixedly connected with a top cap 801, and the top of the locking screw 8 top cap 801 is provided with a cross groove to facilitate screwdriver rotation, and the inside of the locking screw 8 is movably connected with an inner rod 802, and the inner rod 802 runs through Lock the center position of the screw rod 8, and the outer wall of the inner rod 802 is connected with the joint of the locking screw rod 8 by setting threads, and the top of the inner rod 802 is provided with a positive hexagonal screw groove, and the outer side of the inner rod 802 is fixed with a helical gear 8021, and locked The inside of the screw rod 8 is located at the junction of the helical gear 8021 and is provided with an active cavity matching the diameter of the helical gear 8021, and the inner wall around the active cavity is provided with threads to mesh with the helical gear 8021. The cross-section of the positioning e...

Embodiment 3

[0038] see Figure 7-8 , in this embodiment, the top of the limit end 803 is fixedly connected with an anti-off plate 8031, the upper surface of the anti-off plate 8031 is fixedly connected with a vertically arranged telescopic spring 804, and the bottom of the inner rod 802 is provided with a cavity for the anti-off plate 8031 slides up and down and telescopic spring 804 stretches and deforms.

[0039] In this embodiment, when the limiting end 803 is driven by the rotation of the inner rod 802 to move down above the groove on the surface of the embedded block 701, the lower surface of the limiting end 803 will stick to the surface of the embedded block 701, but due to the uncertain thread rotation In this way, when the lower surface of the limiting end 803 is attached to the surface of the embedded block 701, the limiting end 803 cannot accurately correspond to the groove on the surface of the embedded block 701 and snap into it, so the inner rod 802 rotates and presses dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com