High-precision counter torque testing device for gyro motor

A gyro motor and testing device technology, which is applied in the direction of motor generator testing, measuring devices, torque measurement, etc., can solve the problems of test result interference, large test error, and low test accuracy, so as to improve the accuracy and acquisition speed of test equipment Fast, easy-to-acquire results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

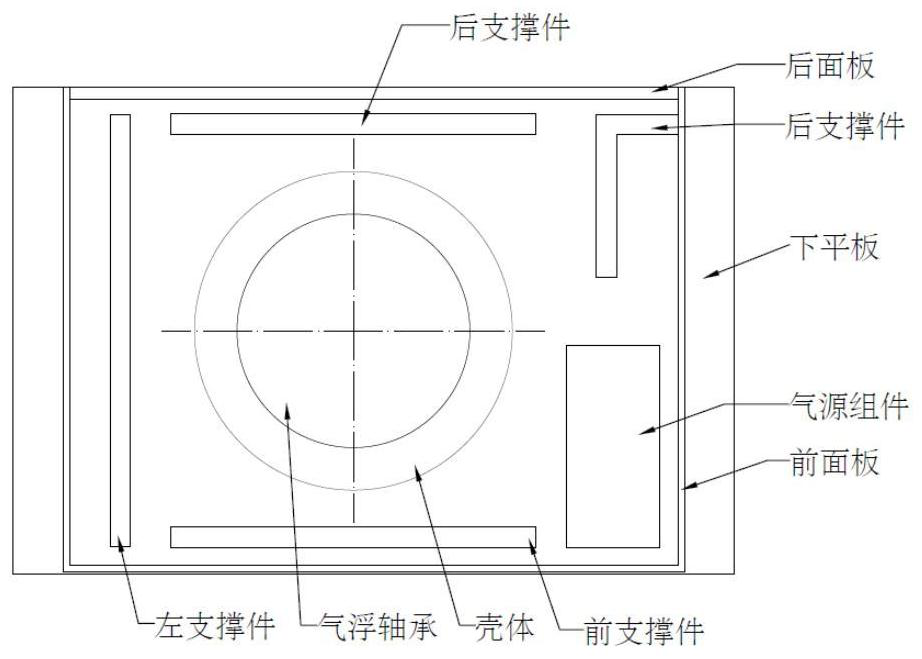

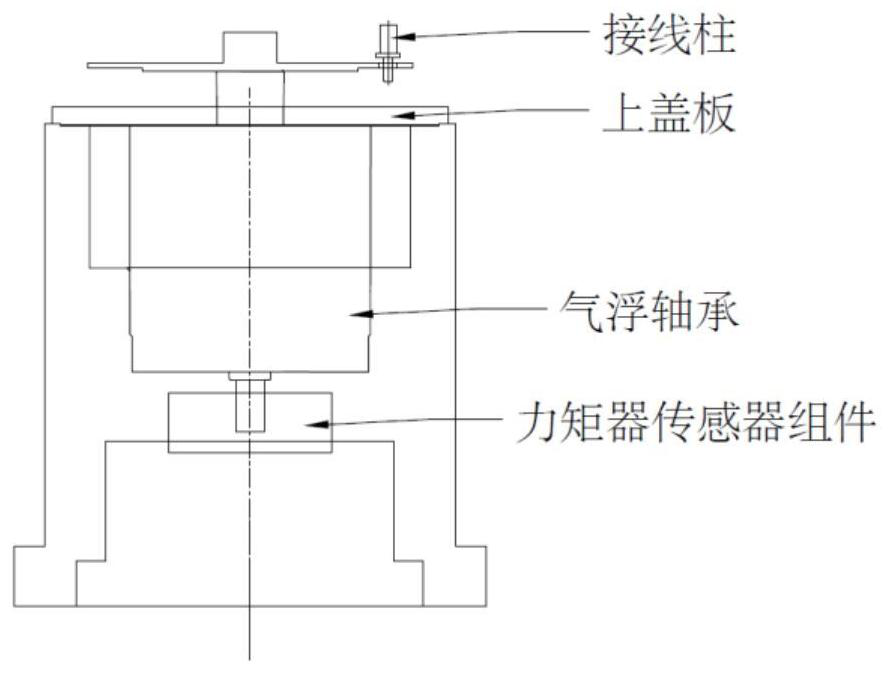

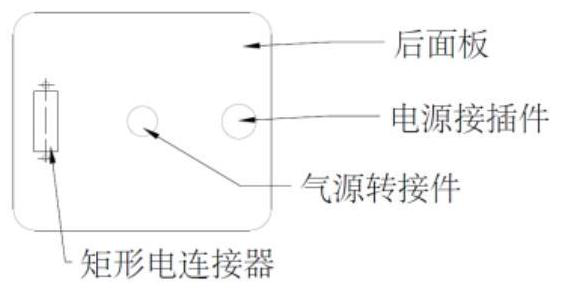

[0032] A high-precision anti-torque test device for gyro motors, including: an upper plate, a lower plate, a dust cover, a terminal post, a transfer tool, an upper cover, a left support, a right support, a front support, and a rear support , Front panel, rear panel, air bearing, shell, torque sensor assembly, air source assembly, rectangular electrical connector, air source adapter, power connector.

[0033] Such as figure 1 As shown, the shell is installed in the middle of the lower plate, the air source assembly is installed in the lower right, the front support is installed in the front, the rear support is installed in the rear, the left support is installed in the left, the right support is installed in the right, and the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com