Small nitrogen sealing structure

A nitrogen-sealed, small-sized technology, applied in the sealing of engines, electrical components, TVs, etc., can solve the problems of difficult disassembly of the sealing method, difficulty in sealing multiple wiring harnesses, etc., and achieves the effect of increasing the number, convenient disassembly, and simple connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

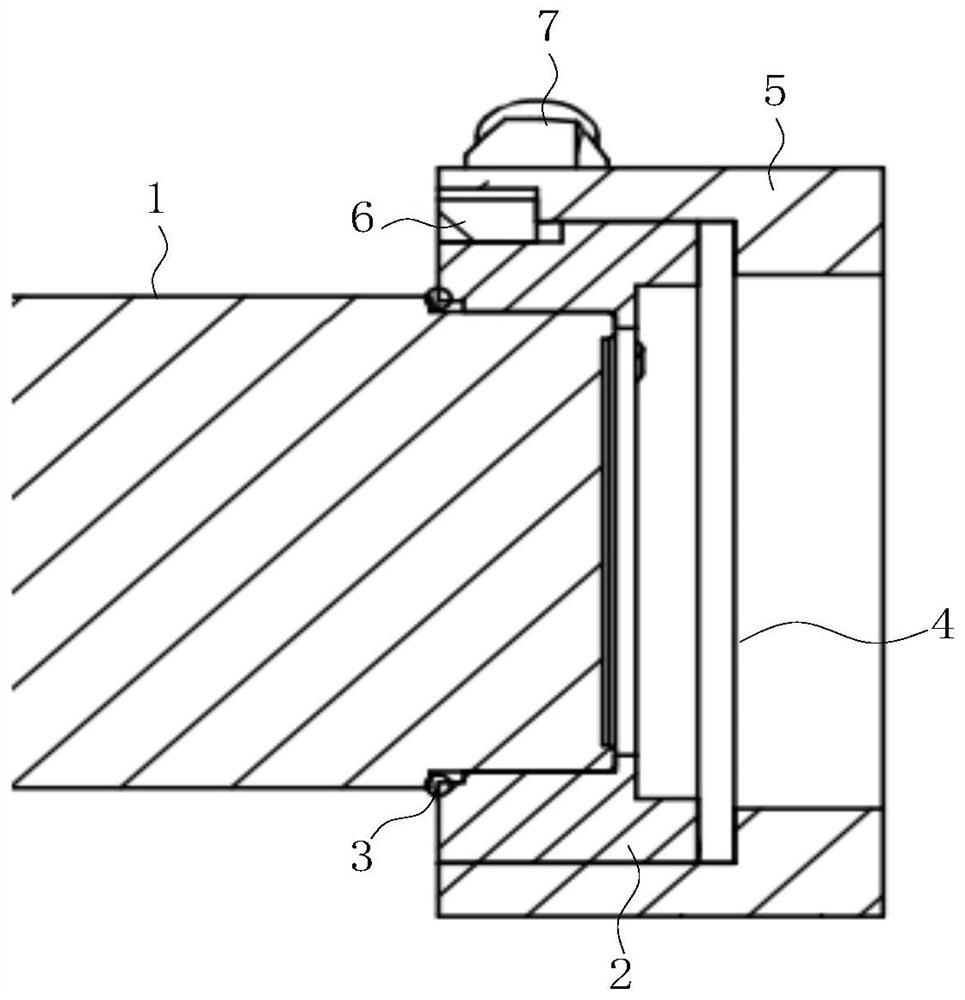

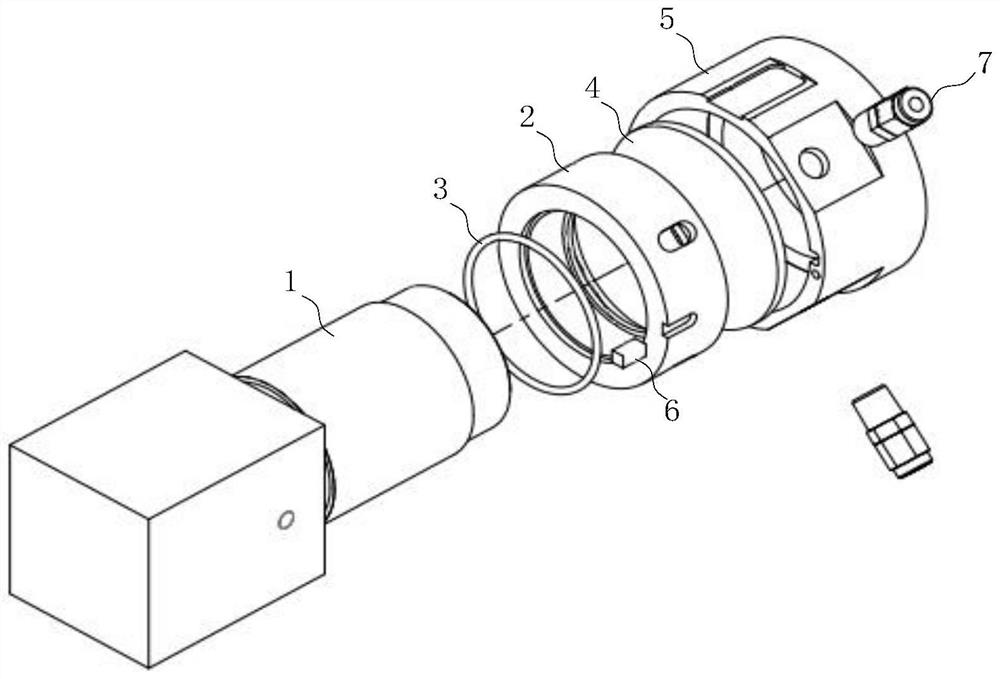

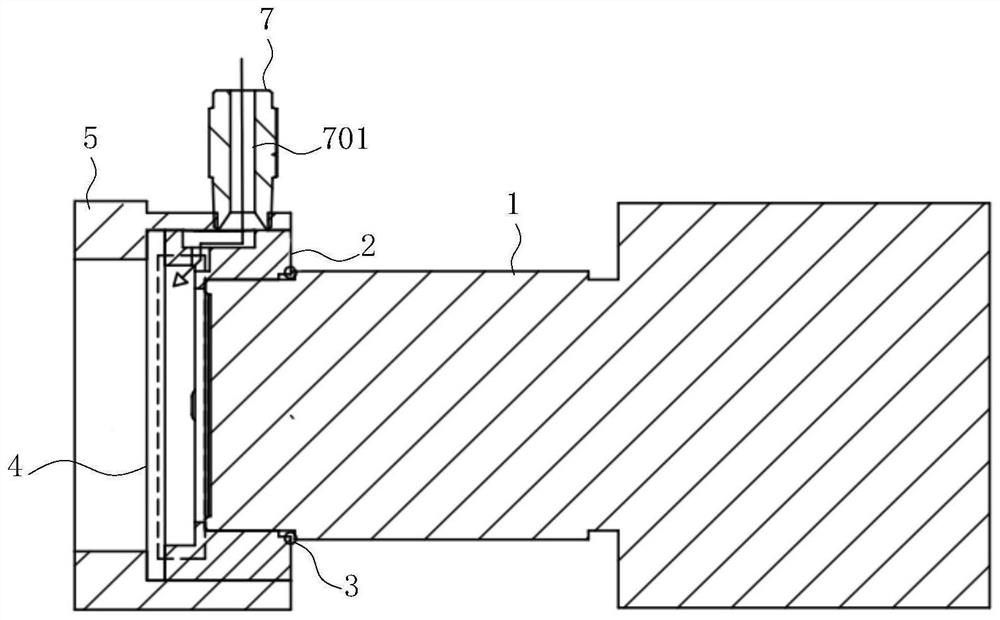

[0020] See attached figure 1 - attached image 3 , a kind of small-scale nitrogen sealing structure of the present invention comprises:

[0021] An inner spacer 2, one end of the inner spacer 2 is arranged coaxially with the stepped surface at the front end of the lens 1;

[0022] The outer fixing seat 5 coaxially arranged on the outer side of the inner spacer ring 2;

[0023] And the inner window glass 4 coaxially arranged in the outer fixing seat 5, one side of the window glass 4 is in contact with the positioning surface of the outer fixing seat 5, and the other side is in contact with the other end of the inner spacer ring 2, and the lens 1 , the inner spacer 2 and the window glass 4 form a nitrogen airtight cabin.

[0024] Both the inner spacer ring 2 and the outer fixing seat 5 are provided with two air holes, and the two air holes on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com