Efficient heat dissipation double-flow-channel water pump

A double-channel, water-pump technology, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as poor cooling efficiency of motors, achieve high cooling efficiency, improve cooling efficiency, and facilitate real-time maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

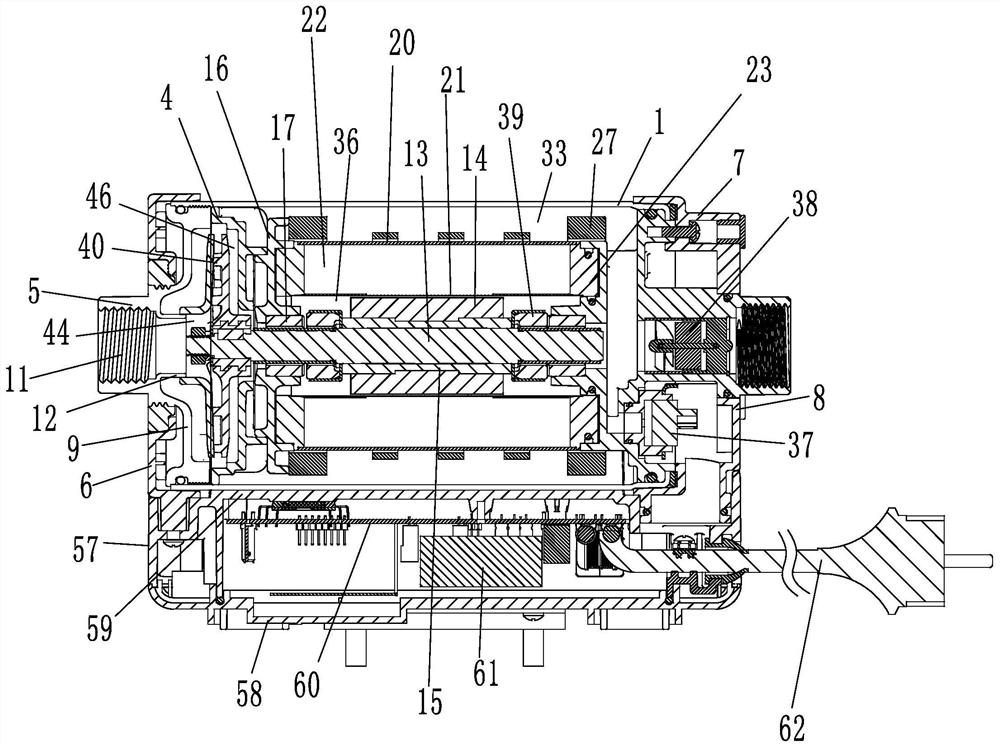

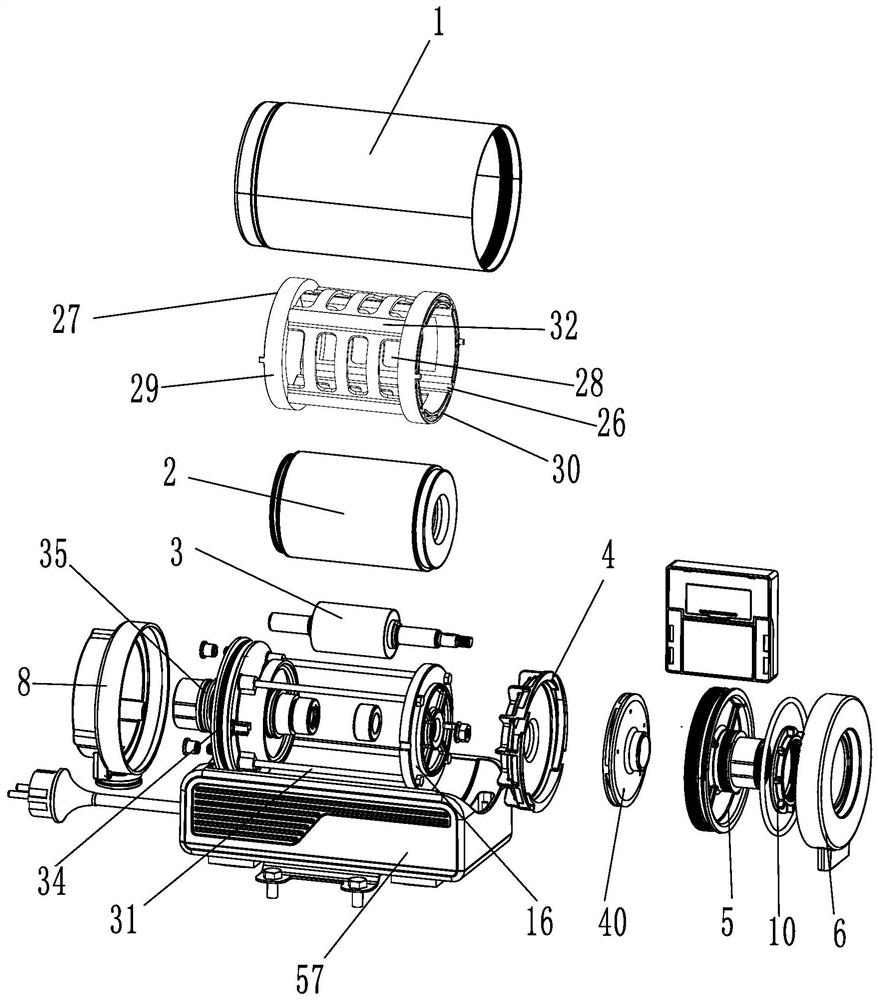

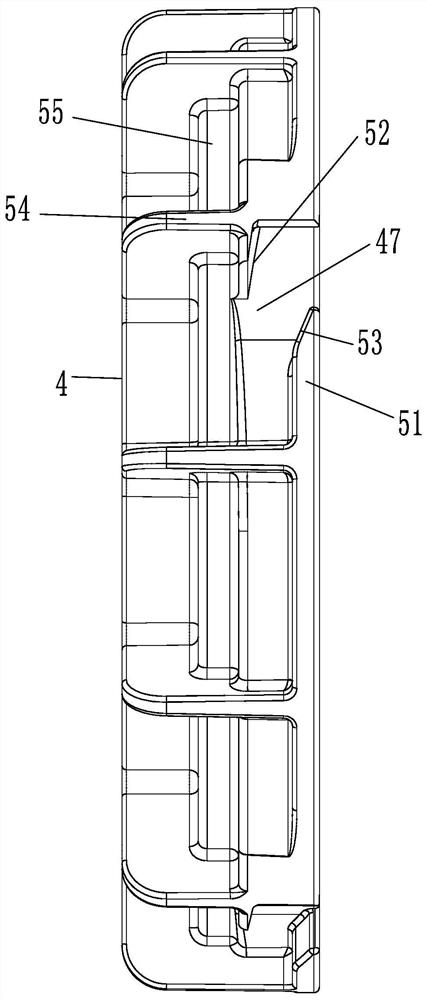

[0055] Such as Figure 1 to Figure 7 As shown, a high-efficiency heat-dissipating double-channel water pump is characterized in that it includes a water pump outer cylinder 1 , a stator assembly 2 , a rotor assembly 3 and a guide casing 4 .

[0056] The shape of the water pump outer cylinder 1 is a cylindrical shape with both ends unobstructed. The water pump also includes a front end cover 5, a front casing 6, a rear end cover 7 and a rear casing 8; along the axial direction of the water pump outer cylinder 1, the front end cover 5. The front housing 6 is respectively fixed on the inner and outer walls of one end of the water pump outer cylinder 1, and the rear end cover 7 and the rear housing 8 are respectively fixed on the inner and outer walls of the other end of the pump outer cylinder. The front end cover 5, the front casing 6, the rear end cover 7 and the rear casing 8 are all circular ring-disk structures. The front end cover 5 includes a front plate body 9 and a fron...

Embodiment 2

[0069] A high-efficiency heat dissipation dual-channel water pump, such as Figure 8 and Figure 9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the shape of the water passage 19 is linear, the cross-sectional shape of the water passage 19 is semicircular, and the axis of the water passage 19 is located on the tangent surface of the inner peripheral side of the bearing 17. Above, the axis of the water passage and the axis of the bearing are arranged obliquely, and the intersection point of the axis of the water passage and the inner peripheral side of the bearing is located in the middle of the bearing axial direction. The water diversion groove 18 is located in the radial direction of the end face of the bearing 17 , chamfers are respectively provided at both ends of the bearing 17 , and the water diversion groove 18 is arranged along the end face of the bearing 17 and the chamfer in a broken line shape.

[0070] When in use, the stator assembly 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com