Heat-conducting wave-absorbing gasket and preparation method thereof

The technology of gasket and wave absorbing filler is applied in the field of thermal conduction wave absorbing gasket and its preparation, which can solve the problem of low thermal conductivity and achieve the effects of suitable hardness, high thermal conductivity, resilience and compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

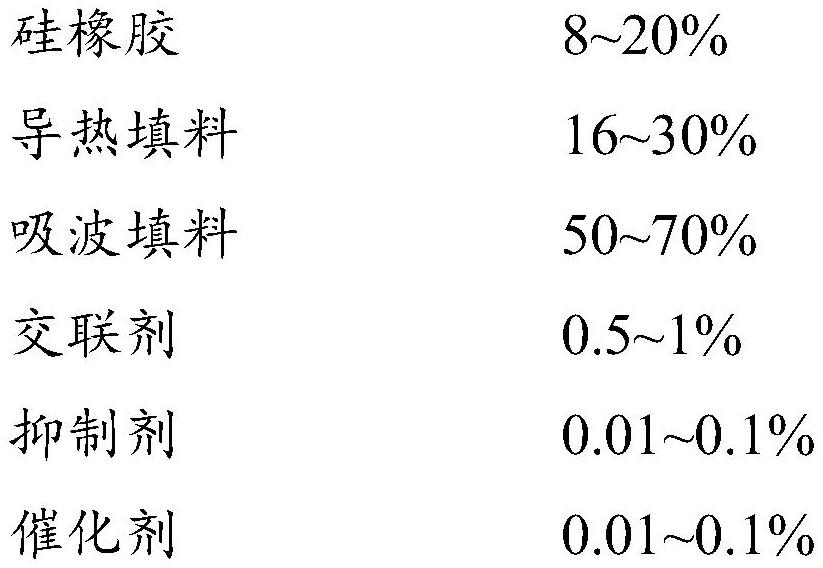

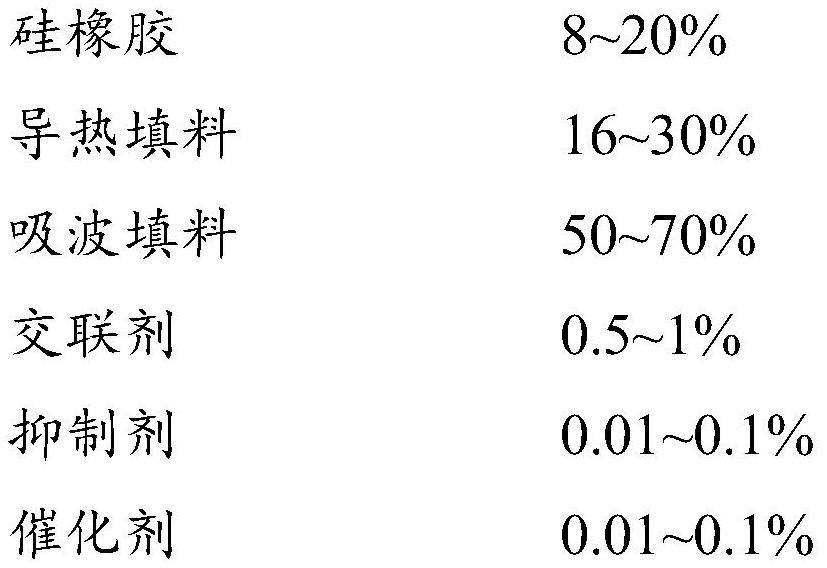

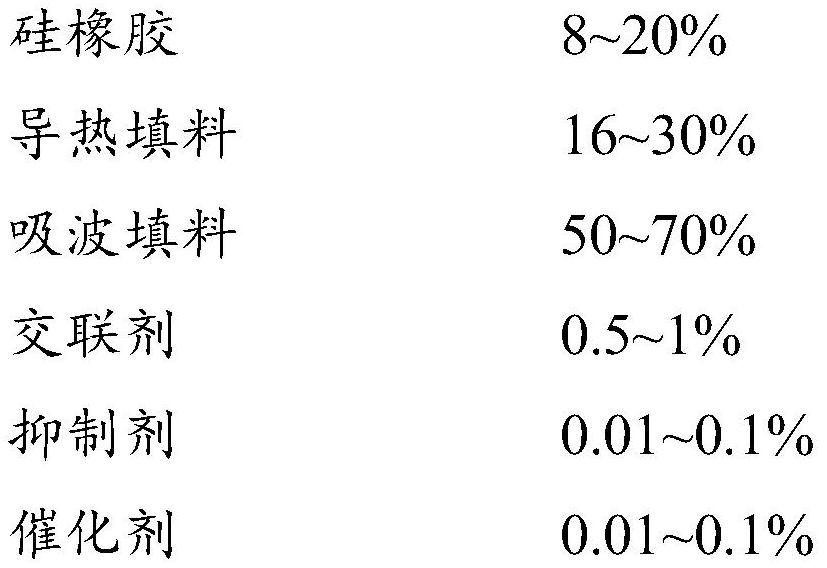

Method used

Image

Examples

Embodiment 1

[0034] Preparation of the heat-conducting wave-absorbing gasket of embodiment 1:

[0035] 10% of silicone rubber with a viscosity of 200cs, 0.9% of hydrogen-containing silicone oil containing 0.18% of active hydrogen, 0.05% of inhibitors, and 0.05% of 2000ppm platinum catalyst were placed in a stirrer with a rotation speed of 25r / min and stirred for 10min to make Mix the liquid components evenly; then add 29% fibrous carbon fiber with a particle size of 200um, 60% spherical iron carbonyl with a particle size of 5um, control the stirrer speed at 60r / min, vacuum -0.09MPa, and continue stirring After 55min, the heat-conducting and wave-absorbing mixture was obtained after the components were mixed uniformly; finally, the heat-conducting and wave-absorbing mixture was transferred to the calender, and the rolling process was carried out through the calender rolls, and the magnetic field orientation was carried out by a curing conveyor furnace with a directional magnetic field (the l...

Embodiment 2

[0036] Preparation of the heat-conducting wave-absorbing gasket of embodiment 2:

[0037]11.9% of silicone rubber with a viscosity of 100cs, 1% of hydrogen-containing silicone oil containing 0.3% of active hydrogen, 0.01% of inhibitors, and 0.02% of 2000ppm platinum catalyst were placed in a stirrer with a rotation speed of 25r / min and stirred for 15min to make Mix the liquid components evenly; then add 17.07% fibrous carbon fiber with a particle size of 100um, 70% spherical carbonyl iron with a particle size of 30um, control the stirrer speed at 50r / min, vacuum -0.09Mpa, and continue stirring for 60min , so that the components are mixed evenly to obtain the heat-conducting and absorbing mixture; finally, the heat-conducting and absorbing mixture is transferred to the calender, and the calendering process is carried out through the calender rolls, and the magnetic field orientation is carried out by a curing conveyor furnace with an oriented magnetic field (the length of the co...

Embodiment 3

[0038] Preparation of the heat-conducting wave-absorbing gasket of embodiment 3:

[0039] 20% of silicone rubber with a viscosity of 500cs, 0.6% of hydrogen-containing silicone oil containing 0.1% of active hydrogen, 0.1% of inhibitors, and 0.07% of 2000ppm platinum catalyst were placed in a stirrer with a rotation speed of 25r / min and stirred for 13min to make Mix the liquid components evenly; then add 23% fibrous carbon fiber with a particle size of 300um, 56.23% spherical carbonyl iron with a particle size of 15um, control the stirrer speed at 60r / min, vacuum -0.09MPa, and continue stirring After 50min, the heat-conducting and wave-absorbing mixture was obtained after the components were mixed uniformly; finally, the heat-conducting and wave-absorbing mixture was transferred to the calender, and the calendering process was carried out through the calender rolls, and the magnetic field orientation was carried out by a curing conveyor furnace with a directional magnetic field ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com