Water-soluble fertilizer for improving apple quality and preparation method and application thereof

A water-soluble fertilizer and apple technology, applied in the field of water-soluble fertilizer and its preparation, can solve the problems of inability to improve apple flavor, single fertilizer effect of water-soluble fertilizer, reduced apple flavor, etc., and achieve the effects of good absorption, rapid dissolution, and fruit expansion promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides the preparation method of the water solubility fertilization, including the steps of:

[0046] (1) The components in the water solubility fertilizing fertilization are mixed with water, dissolved to obtain intermediate liquid 1;

[0047] (2) The intermediate liquid is 1 homogenesis to obtain intermediate liquid 2;

[0048] (3) The intermediate liquid 2 was dried to give water-soluble fat.

[0049] In the present invention, the mass ratio of the water-soluble fat and water is 1: 1 to 2, preferably 1: 1.5;

[0050] Step (1) The dissolution is stirred and dissolved;

[0051] The stirring speed is 120 to 150 rpm, preferably 135 rpm;

[0052] The dissolved time is 30 to 40 min, preferably 35min;

[0053] The dissolved temperature is 50 to 60 ° C, preferably 55 ° C.

[0054] In the present invention, the homogeneous pressure of step (2) is 160 to 180 MPa, preferably 170 MPa;

[0055] The homogeny time is 10 to 15 min, preferably 12.5 min.

[00...

Embodiment 1

[0080] Potassium phosphate 400g, urea 200g, ammonium nitrate 20g, sucrose 90g, ethylene 10g, deformed acid 15g, chelating iron 30g, chelated zinc 10g, chelating copper 40g, chelated manganese 20g, chelating magnesium 20g, boric acid 50 g, potassium molybdate, 70 g of hyaluronate, 70 g of sodium hyaluronate, adding 1500 g of water, dissolved at 50 ° C, and dissolved under conditions of 120 rpm, and dissolved for 40 min to give intermediate liquid 1.

[0081] The intermediate liquid 1 was centrifuged under 10000 rpm under 10 min in 180 MPa homogeneous machine, and the slag was taken. The filter residue was spray dried 20s under conditions of 8 ° C in the air supply temperature of 95 ° C to obtain water.

[0082] 100 g of water solution is dissolved in 1000 ml of water, spraying apples, spraying 1000ml per apple tree, spraying every 12D.

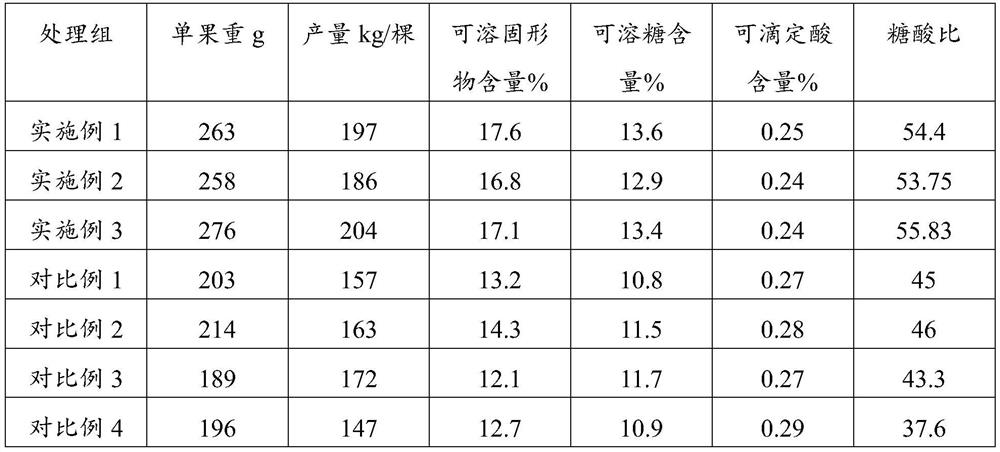

[0083] The Red Fuji apple was harvested on October 27 to determine the coloring level of Red Fuji Apple and the chromaticity results were calculat...

Embodiment 2

[0085] Potassium phosphate 500g, urea 150g, 10 g of nitrate, 20 g of sucrose 70g, ethylene 30g, potassium molybdate, 90 g of hyaluronate, 1050 g of water, dissolved at 60 ° C, and dissolved under conditions of 150 rpm, resulting in intermediate liquid 1.

[0086] The intermediate liquid 1 was homogenized in a homogeneous machine of 160 MPa, and was centrifuged at 12000 rpm for 10 min, and filter residue was taken. The filter residue was spray dried under conditions of 180 ° C in the air temperature of 95 ° C, resulting in water solution.

[0087] 100 g of water solution is dissolved in 1200 ml of water, spraying apples, spraying 1200ml per apple tree, spraying every 15D.

[0088] The Red Fuji apple was harvested on October 27 to determine the coloring level of Red Fuji Apple and the chromaticity results were calculated as shown in Table 1. Randomly selected 20 apples to determine the single fruit weight of each apple, weigh the yield of apple produced by each apple tree; determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com