Soil and gravel sorting system for river regulation site and using method thereof

A sorting system and technology for soil and gravel, applied in chemical instruments and methods, solid separation, sieve, etc., can solve the inconvenience of automatic feeding operation of soil and gravel, automatic vibration screening and classification of sand and gravel, and inconvenient material collection operation, etc. It can improve the vibration amplitude and vibration screening efficiency, the device structure is easy to operate, and the device structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

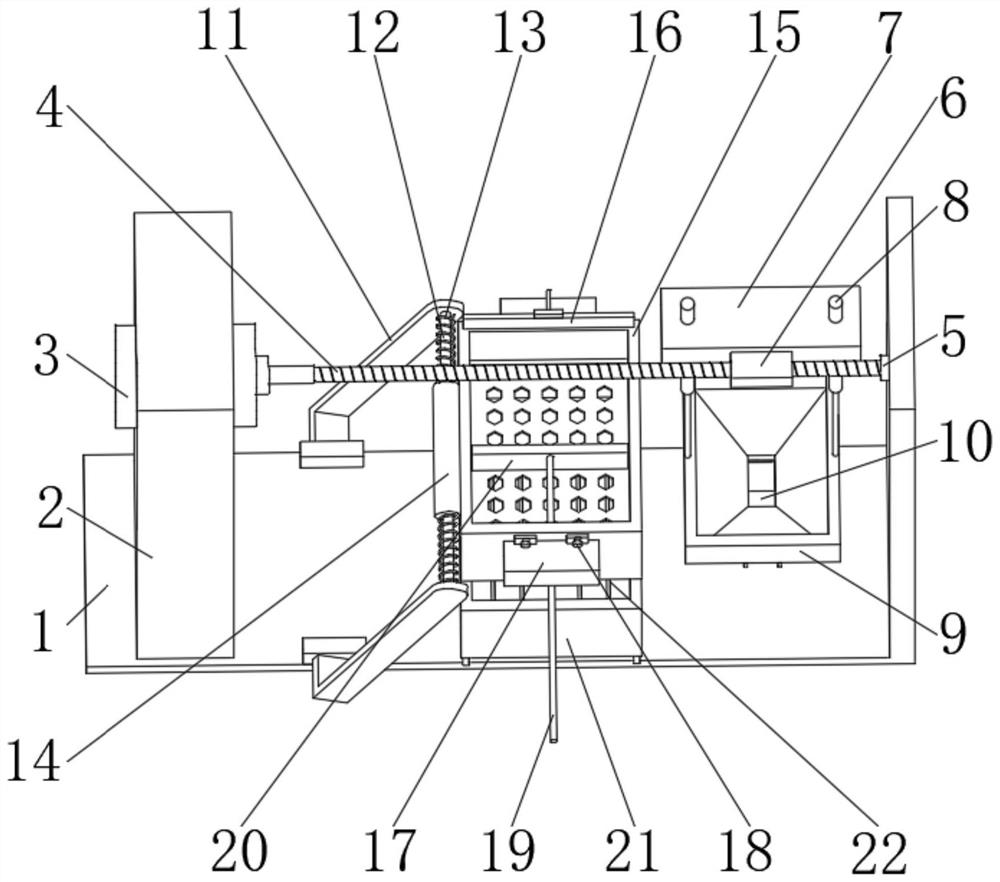

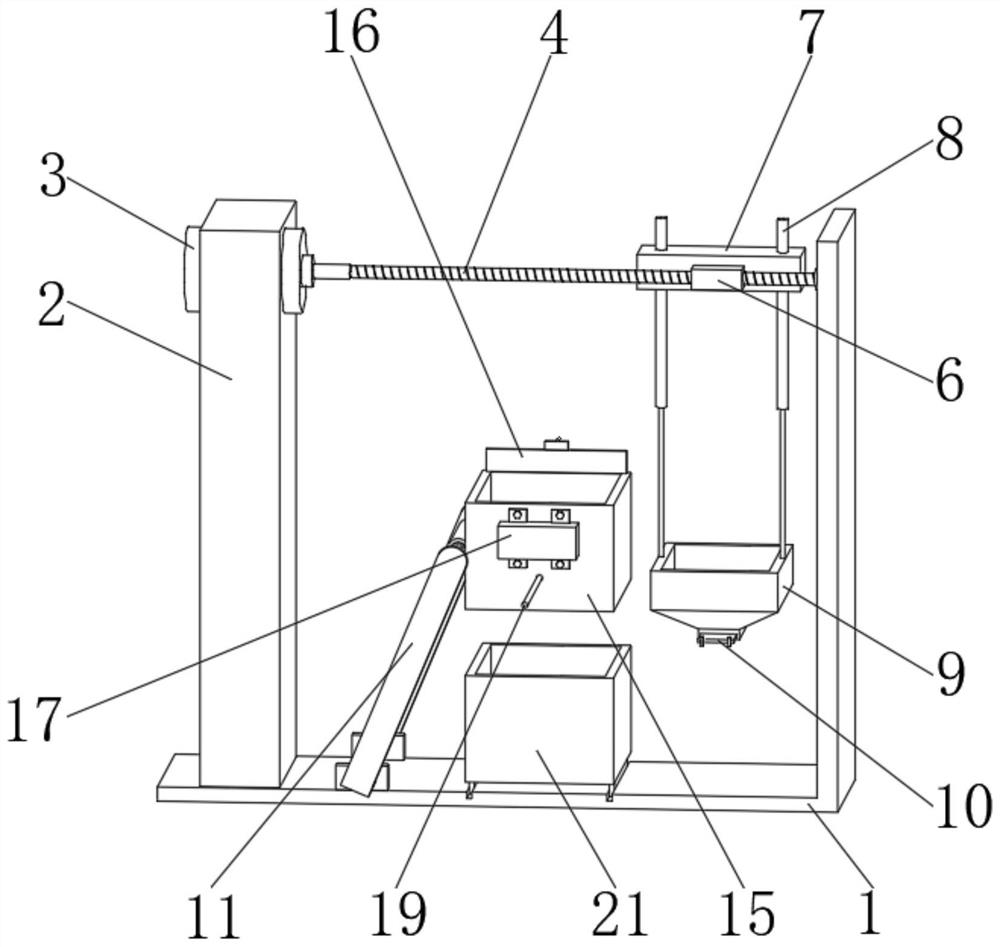

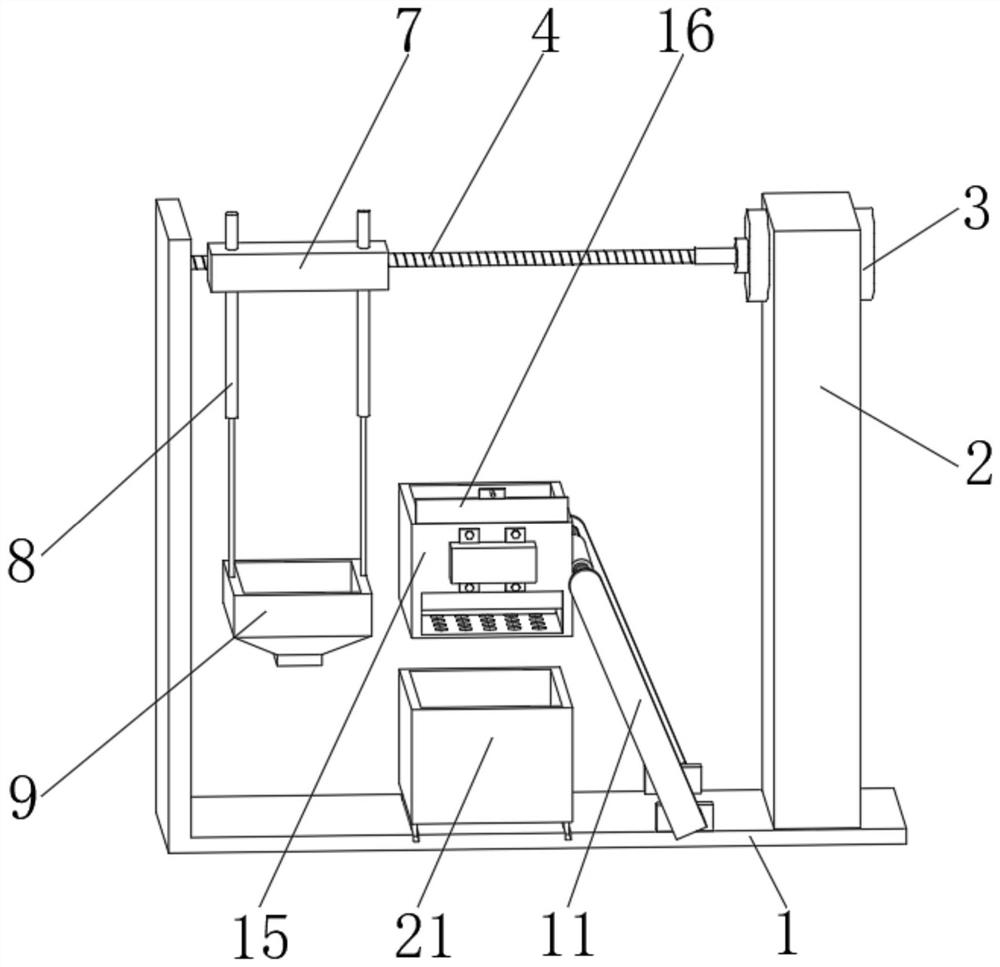

[0031] see Figure 1-4 As shown, a system for sorting soil, sand and gravel for use in the field of river channel regulation and its use method includes a bottom plate 1 and a support frame 11, a support seat 2 is arranged on the top of the bottom plate 1, and a servo motor 3 is installed inside the support seat 2, and the servo The end of the motor 3 is connected with a transmission screw 4, and the end of the transmission screw 4 is equipped with a bearing seat 5, the outer side of the transmission screw 4 is provided with a threaded pipe 6, and the side of the threaded pipe 6 is provided with a connecting seat 7 An electric telescopic rod 8 is installed on the inner side of the connecting seat 7, and the end of the electric telescopic rod 8 is provided with a collecting bucket 9, and the bottom of the collecting bucket 9 is provided with a discharge plate 10.

[0032] The connection seat 7 constitutes a transmission structure through the threaded pipe 6 and the transmission...

Embodiment 2

[0035] see Figure 1-5 As shown, compared with Example 1, as another embodiment of the present invention, the support frame 11 is arranged on the side of the support seat 2, and the end of the support frame 11 is provided with an engaging rod 12, and the outside of the engaging rod 12 is provided with Elastic spring 13, and the end of elastic spring 13 is provided with sleeve pipe 14, and the side of sleeve pipe 14 is provided with screening box 15, and the end of screening box 15 is provided with baffle plate 16, and the outer wall of screening box 15 is provided with vibration 17, and the end of the vibrator 17 is connected with a connecting buckle 18, the inside of the screening box 15 is penetrated with a movable rod 19, and the end of the movable rod 19 is provided with a pushing plate 20, and the bottom of the screening box 15 is provided with an aggregate Box 21, and the inner side of the collecting box 21 is provided with a water leakage hole 22.

[0036] The casing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com