Quenching water device suitable for long-period operation of acetylene furnace

A long-cycle, acetylene furnace technology, applied in the field of quenching water devices, can solve the problems of unfavorable installation and maintenance, limit the normal operation cycle of acetylene furnace, inconvenient procurement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

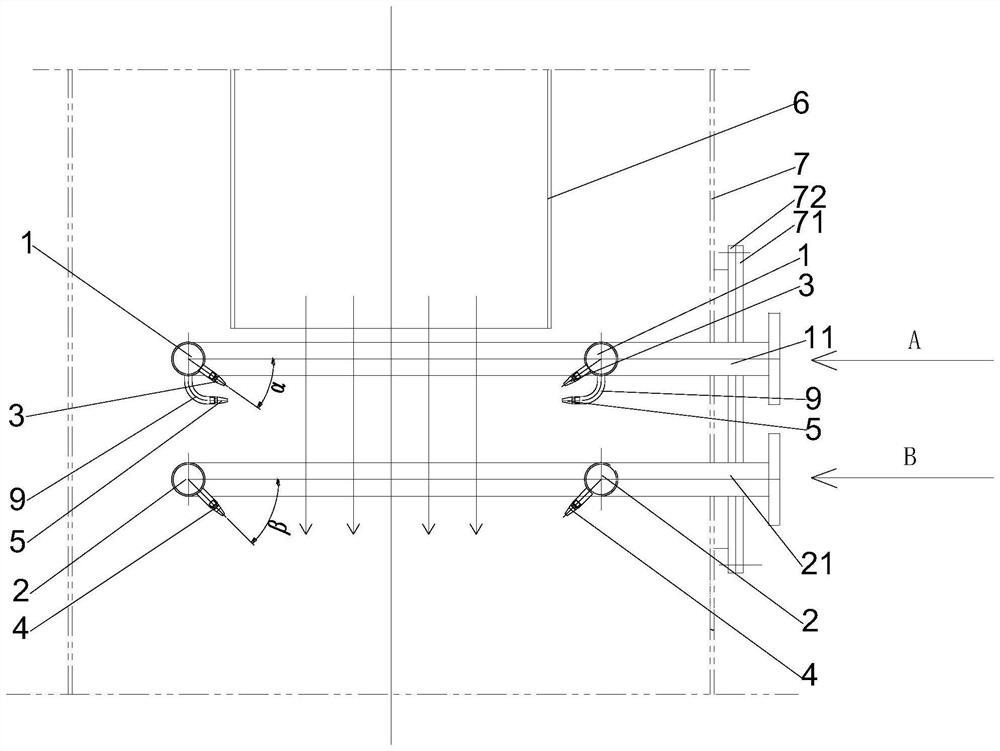

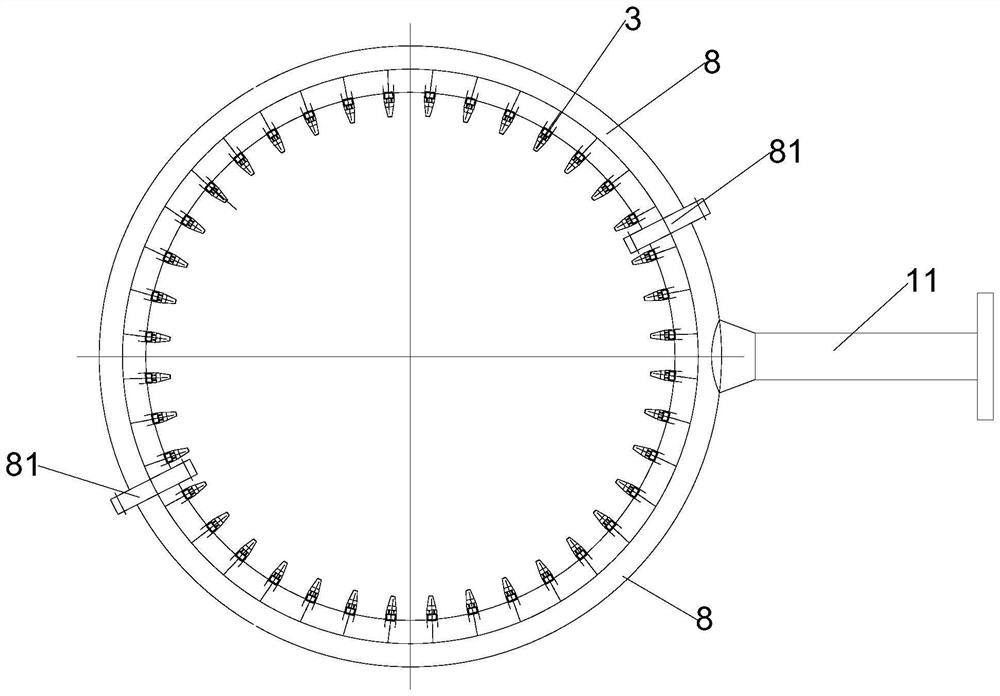

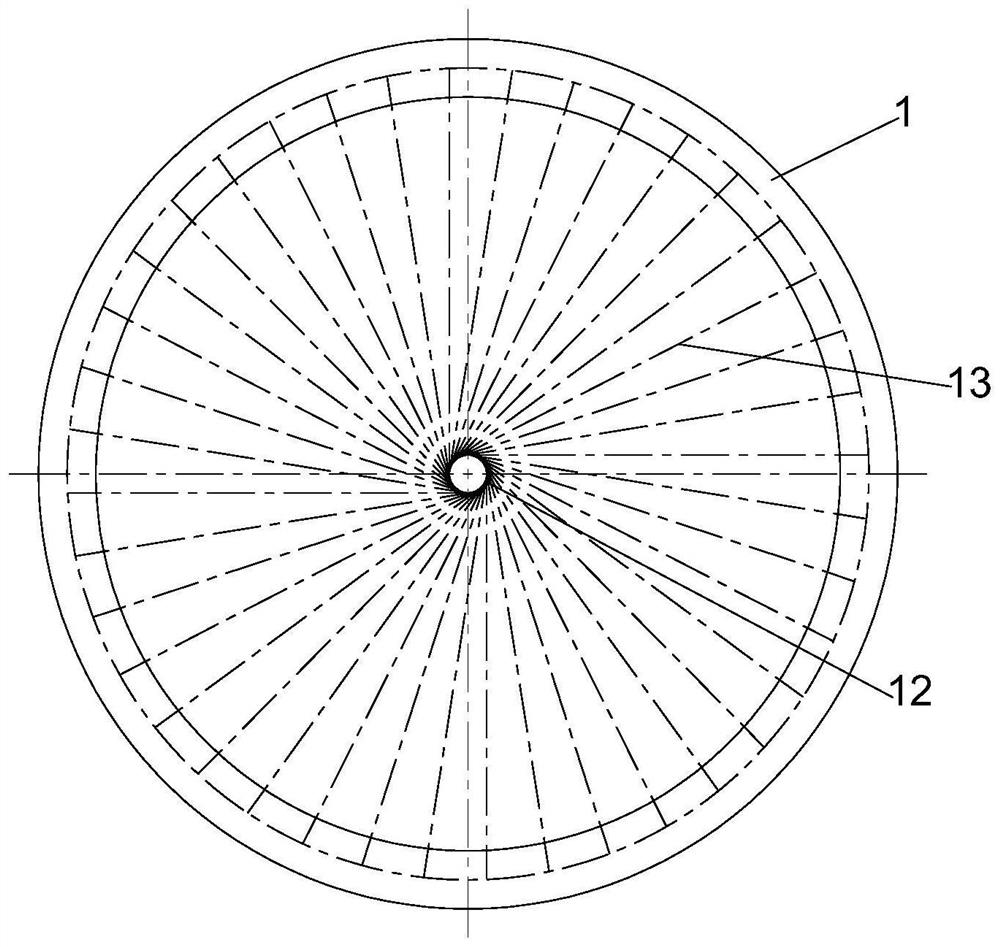

[0032] Such as Figure 1 ~ Figure 3 As shown, a quenching water device suitable for long-term operation of an acetylene furnace in this embodiment includes a first layer of water spray ring 1 and a second layer of water spray ring 2 arranged up and down, and the first layer of water spray ring 1 Located above the second layer of water spray ring 2; the first layer of water spray ring 1 is provided with a plurality of first nozzles 3 arranged obliquely downward, and the second layer of water spray ring 2 is provided with multiple A second nozzle 4 is arranged obliquely downward, and a plurality of third nozzles 5 are connected to the bottom of the first layer of water spray ring 1, and the third nozzles 5 are located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com