Intelligent printing and dyeing wastewater treatment device

A treatment device, printing and dyeing wastewater technology, applied in the field of printing and dyeing, can solve the problems that the fiber cannot be cleaned, and it is difficult to remove the fiber in the wastewater, so as to achieve the effect of improving efficiency and intelligence, and speeding up the flow screening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

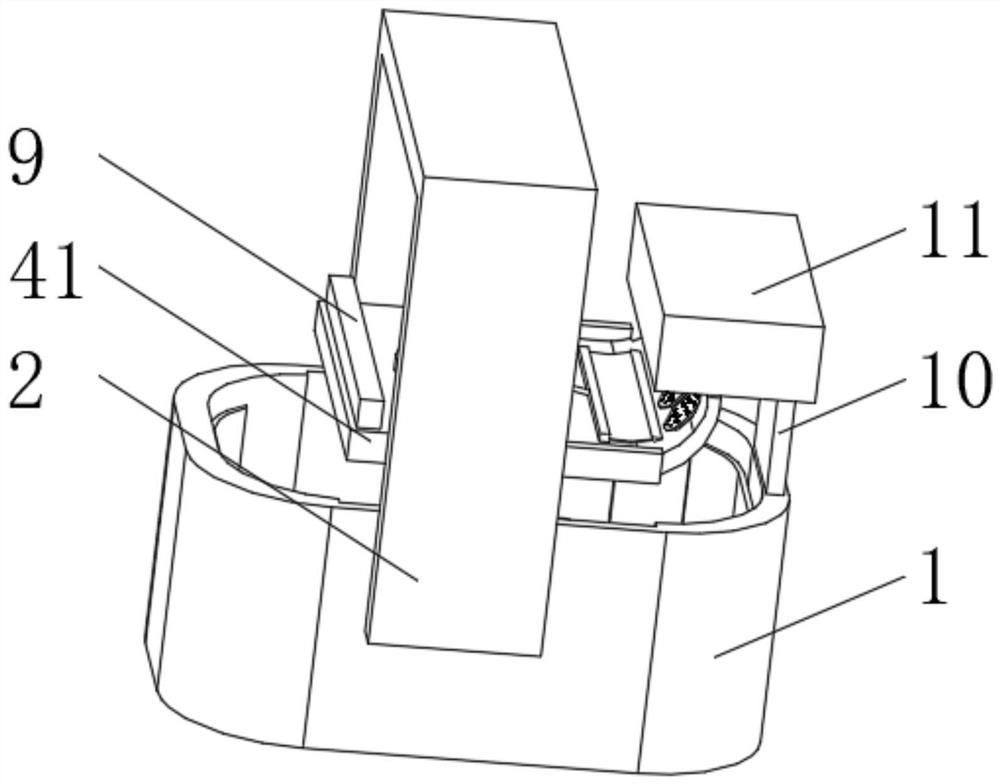

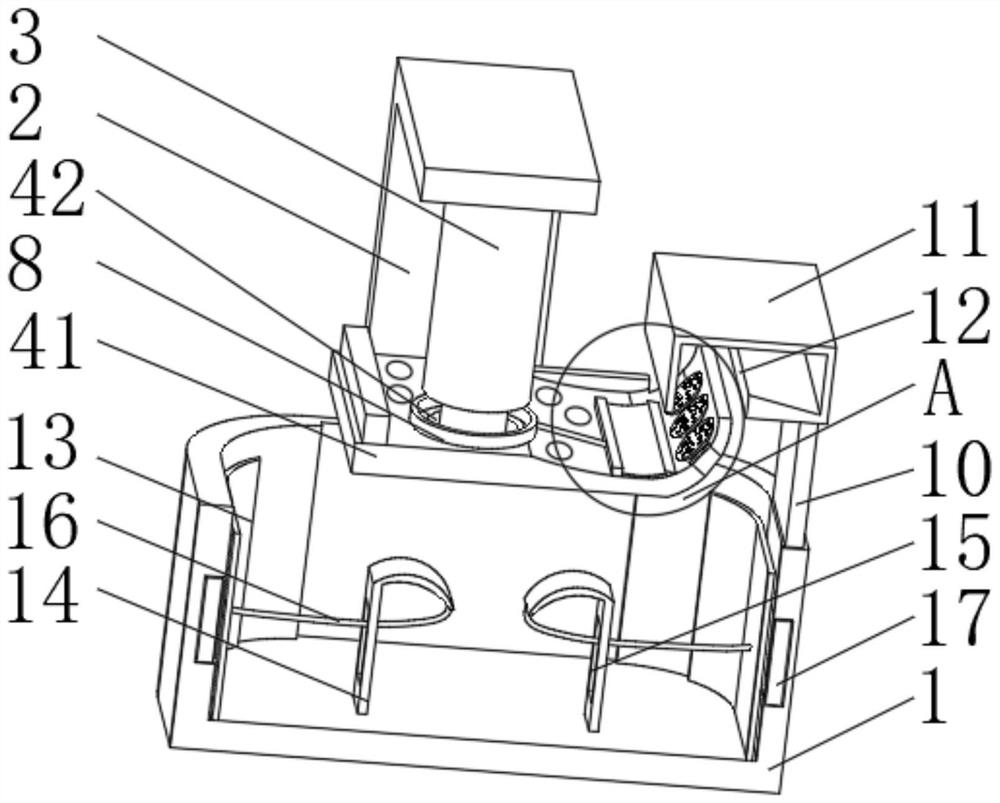

[0034] see Figure 1-4 , the present invention provides a technical solution: an intelligent printing and dyeing wastewater treatment device, including a waste water pool 1, a bracket 2 is fixedly connected to the outside of the waste water pool 1, a hydraulic cylinder 3 is fixedly connected to the inner bottom of the Susohu bracket 2, and the hydraulic cylinder The bottom set of 3 has:

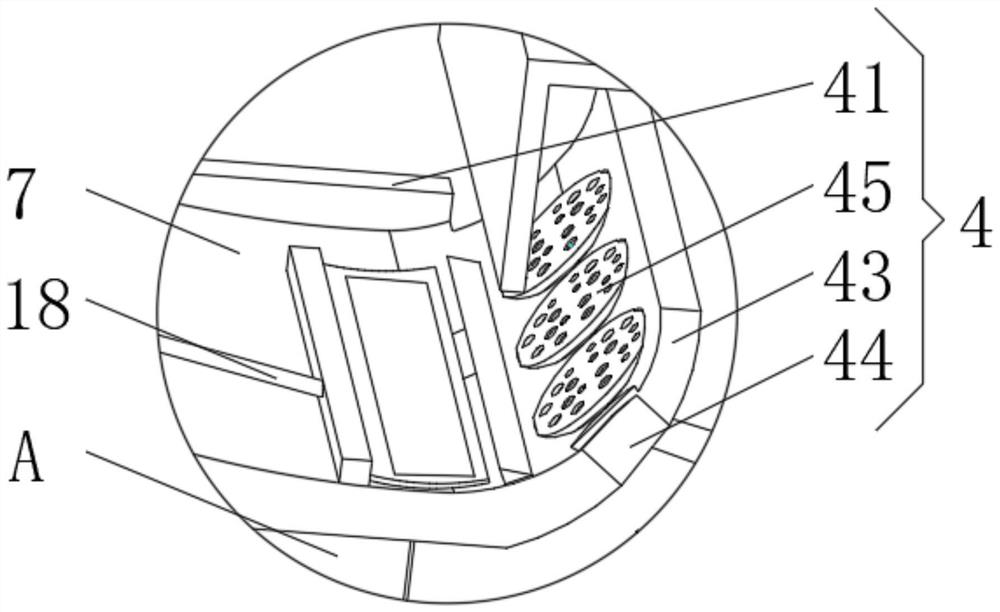

[0035]Screening device 4, the screening device 4 has a screening plate 41, both sides of the inner wall of the waste water tank 1 are provided with longitudinal chute, the screening plate 41 extends to the inside of the longitudinal chute and is slidably connected with the inner wall of the longitudinal chute The top of the screening plate 41 is provided with a mounting hole 42, and one end of the hydraulic cylinder 3 extends to the inside of the mounting hole 42 and is rotatably connected with the screening plate 41. One side of the screening plate 41 is connected with an arc-shaped seesaw 4...

Embodiment 2

[0043] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a booster device 6 is provided at the bottom of the hydraulic cylinder 3, the booster device 6 has a water storage tank 61, and the water storage tank 61 is evenly opened on the screen plate 41 The top, the inner bottom of the water storage tank 61 is fixedly connected with an elastic plate 62 , and the top of the elastic plate 62 is fixedly connected with a water storage plate 63 .

[0044] The inner bottom of the waste water pool 1 is slidably connected with a water pushing plate 13, and the inner bottom of the waste water pool 1 is fixedly connected with an arc-shaped spring plate 14. One side of the arc-shaped spring plate 14 is provided with a guide hole 15, and the top of the arc-shaped spring plate 14 One end is fixedly connected with a traction rope 16 , and the end of the traction rope 16 away from the arc spring plate 14 passes through the guide hole 15 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com