Biogas slurry enzymolysis fermentation tank capable of quantitatively adding enzymolysis agent

A fermentation tank and enzymolysis agent technology, applied in the field of fermentation tanks, can solve the problems of inability to add, lack of fermentation tanks, inconvenient adjustment of dosage control, etc., to achieve the effect of improving enzymolysis efficiency, improving fermentation efficiency, and reducing manpower output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

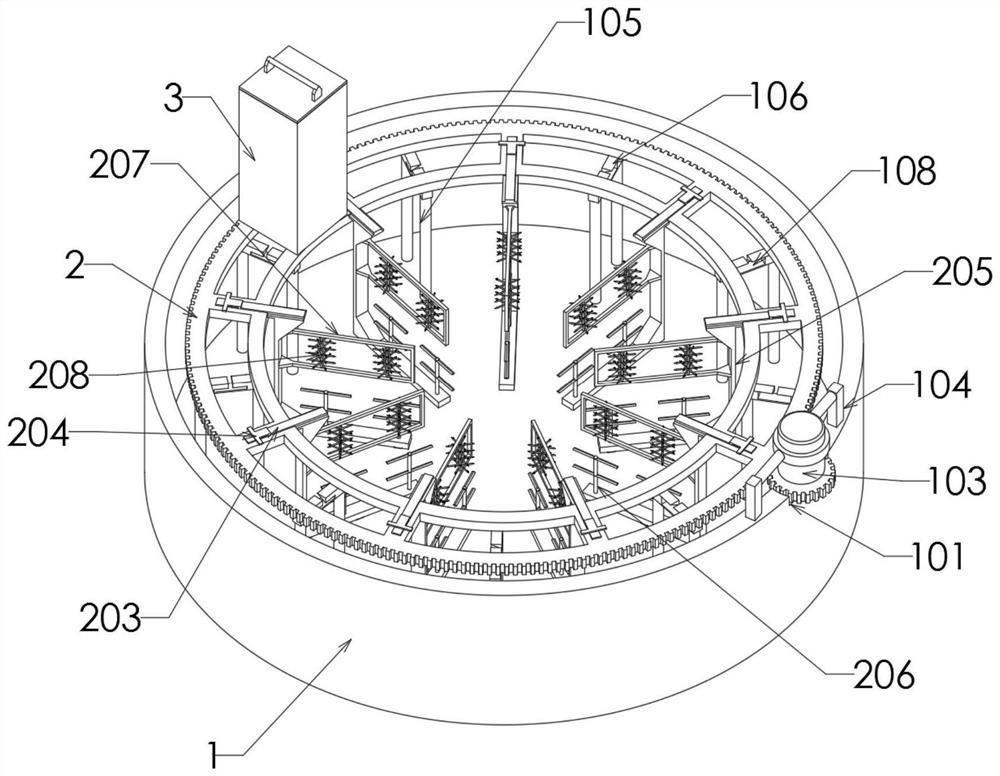

[0030] Example: Please refer to Figure 1 to Figure 8 :

[0031]The present invention proposes a biogas slurry enzymatic fermentation tank capable of quantitatively adding an enzymatic hydrolysis agent, comprising: a main body 1; the main body 1 is the main body of the fermentation tank, and the main body 1 is a disc-shaped structure, so that the biogas slurry can be stored inside the main body 1 Enzymolysis, the inside of the main body 1 is provided with support rods 105, the top of the two support rods 105 is provided with a contact piece 106, and the top of the contact piece 106 is provided with a pull groove 108 inside, the pull groove 108 is a T-shaped structure, and the pull groove 108 The upper part of the inside is an inclined structure, which is used to contact the bottom of the pull piece 304, and then pull the pull piece 304 to move downward, so that the moving rod 303 can also move downward, so that the enzymolysis agent can be discharged through the trough 305; P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com