Preparation method and application of photo-cured polyurethane with self-healing property and shape memory property

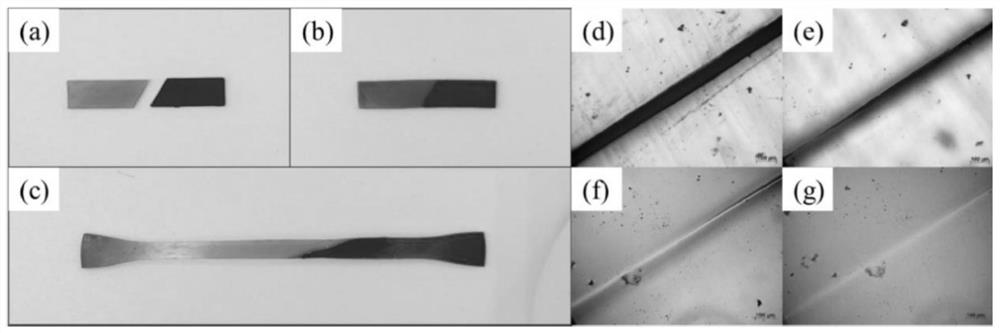

A polyurethane and self-healing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy aging, short service life of polymer materials, and less research on crystal side chain self-healing, and achieve the effect of repairing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Preparation of quaternized dihydroxyethylene glycol: get 1.19g (0.01mol) N-methyldiethanolamine (MDEA) and 3.94g (0.01mol) bromodocosane in a three-necked flask, set the temperature At 100°C, the reaction was stirred for 12 hours to obtain quaternized dihydroxyethylene glycol (0.01mol).

[0033] (2) Preparation of polyurethane hard segment: Take 5.13g (0.01mol) of quaternized dihydroxyethylene glycol and 3.36g (0.02mol) of hexamethylene diisocyanate (HDI) into a three-necked flask for mixing, drop 3-4 Drop dibutyltin dilaurate (DBTDL) and react at 60°C for 2 hours. When the NCO value reaches the theoretical value, the reaction is stopped to obtain a polyurethane hard segment component, which is recorded as product 1 (0.01mol).

[0034] (3) Preparation of polyurethane soft segment: Take 2.91g (0.015mol) tetraethylene glycol (TEG) and 1.68g (0.01mol) hexamethylene diisocyanate (HDI) into a three-necked flask, drop 3-4 drops of dilaurel Dibutyltin dibutyltin (DBTDL) w...

Embodiment 1

[0039] (4) Preparation of UV-cured polyurethane: Take 7.64g (0.009mol) of product 1 and 0.46g (0.001mol) of product 2 into a three-necked flask, add 3-4 drops of dibutyltin dilaurate (DBTDL), at 60°C After reacting for 2 hours, 2.21 g (0.017 mol) of hydroxyethyl methacrylate (HEMA) was added, and the reaction was continued for 2 hours to obtain a polyurethane emulsion.

[0040] (5) Curing of polyurethane: Take 5g of polyurethane emulsion, add 0.25g of 1173 photoinitiator, stir and coat on the sample plate, put it on a UV curing machine to cure for 30-60s, and then get UV cured with self-healing properties and shape memory Resistant polyurethane PU1.

Embodiment 2

[0042] (4) Preparation of UV-cured polyurethane: Take 6.79g (0.008mol) of product 1 and 0.92g (0.002mol) of product 2 into a three-necked flask, add 3-4 drops of dibutyltin dilaurate (DBTDL), at 60°C After reacting for 2 hours, 1.82 g (0.014 mol) of hydroxyethyl methacrylate (HEMA) was added, and the reaction was continued for 2 hours to obtain a polyurethane emulsion.

[0043] (5) Curing of polyurethane: Take 5g of polyurethane emulsion, add 0.25g of 1173 photoinitiator, stir and coat on the sample plate, put it on a UV curing machine to cure for 30-60s, and then get UV cured with self-healing properties and shape memory Resistant polyurethane PU2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com