Transportation equipment for rubber rods for tire processing

A technology of transportation equipment and rubber rods, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., and can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

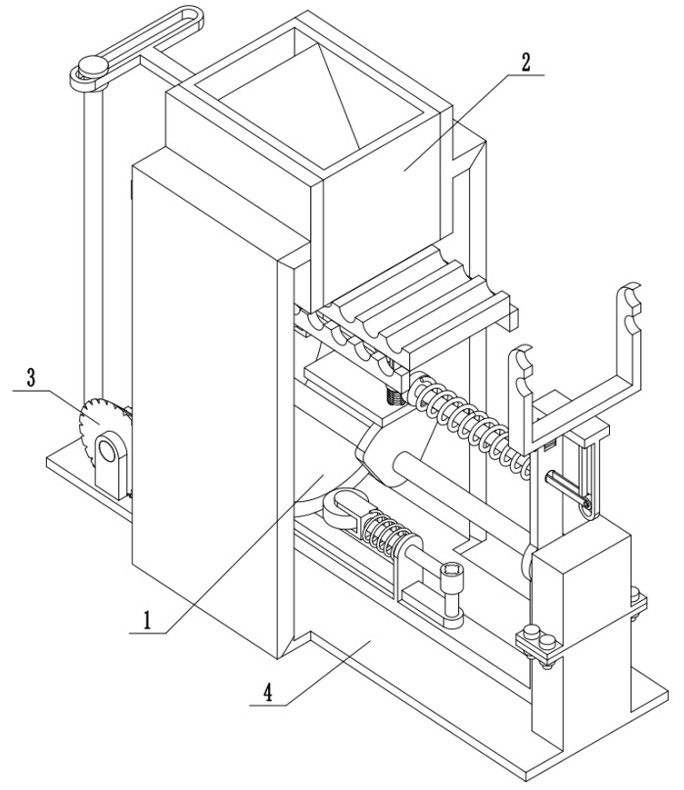

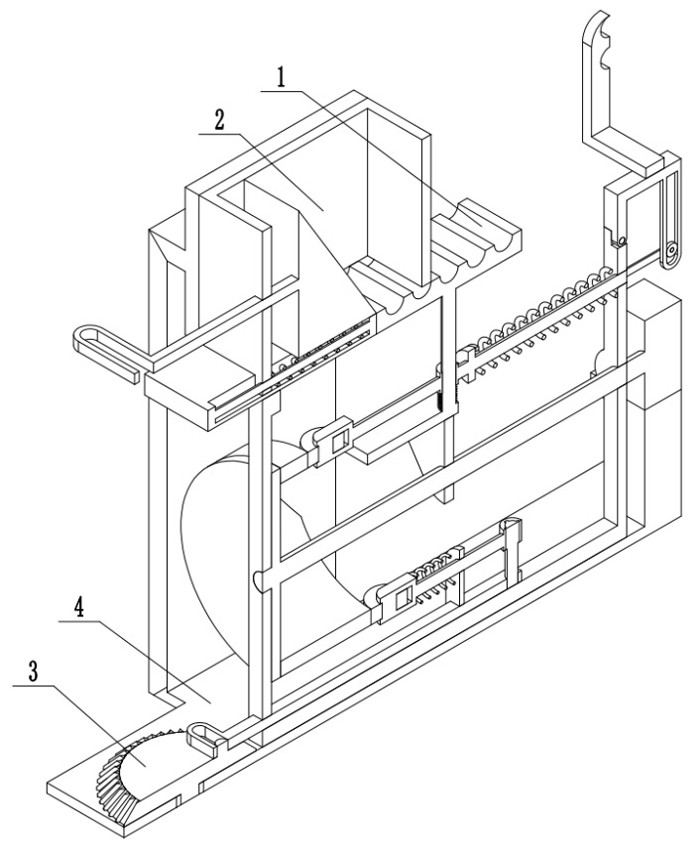

[0025] 1. Combine below Figure 1-9 Description of this embodiment, a transportation device for processing rubber rods for tires, including a carrying part 1, a material box assembly 2, a transmission assembly 3, and a connecting frame assembly 4, wherein the carrying part 1 is connected to the connecting frame assembly 4 Connection, the material box assembly 2 is connected with the connecting frame assembly 4, the transmission assembly 3 is connected with the carrying part 1, and the transmission assembly 3 is connected with the material box assembly 2;

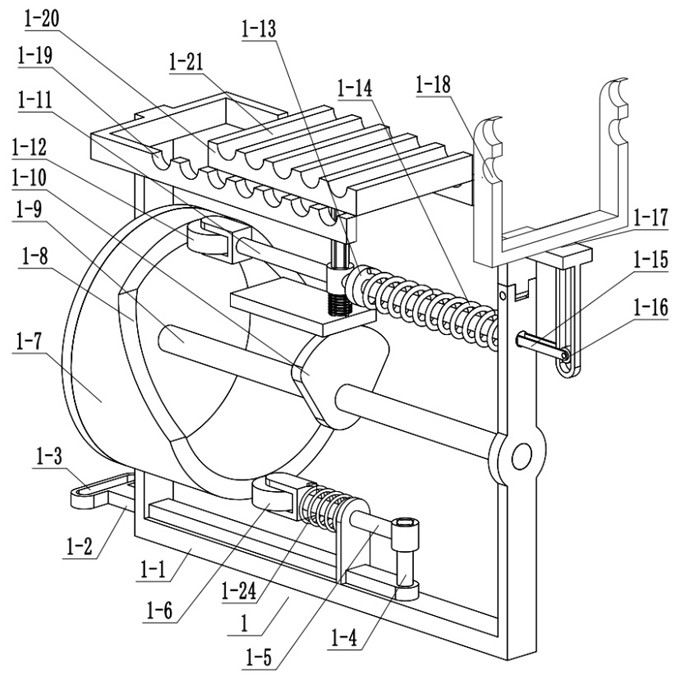

[0026]The carrying part 1 includes a carrying bracket 1-1, a lower end slide bar 1-2, a lower end matching chute 1-3, a hinge column 1-4, a lower end driving slide bar 1-5, a lower end driving roller 1-6, a driving Sleeve 1-7, outer edge 1-8, middle end rotating column 1-9, middle end cam 1-10, upper end driving slide rod 1-11, upper end driving roller 1-12, limit boss 1-13, Spring two 1-14, driving frame 1-15, driving fram...

specific Embodiment approach 5

[0030] Combine below Figure 1-9 Describe this embodiment. This embodiment will further explain Embodiment 1. The connecting frame assembly 4 includes a connecting frame body 4-1, a matching waist groove 4-2, an upper end fixing plate 4-3, an input motor 4-4, and a matching waist groove 4-2 is arranged on the connecting frame body 4-1, the upper fixing plate 4-3 is fixedly connected with the connecting frame body 4-1, the input motor 4-4 is fixedly connected with the connecting frame body 4-1, and the input motor 4-4 The output shaft is fixedly connected with the middle-end rotary column 1-9, the bevel gear turret 3-1 is fixedly connected with the inner end of the matching waist groove 4-2, and the upper end fixed plate 4-3 is fixedly connected with the outer frame 2-1 of the material box. The bracket 1-1 is fixedly connected with the carrying bracket 1-1.

[0031] A kind of transportation equipment for processing rubber rods for tires of the present invention, its working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com