Transverse stator blade assembling method and positioning tool

A technology for positioning tooling and static blades, which is applied to manufacturing tools, workpiece clamping devices, etc., can solve problems such as affecting assembly accuracy, and achieve the effect of convenient operation, simple structure, and guaranteeing assembly accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

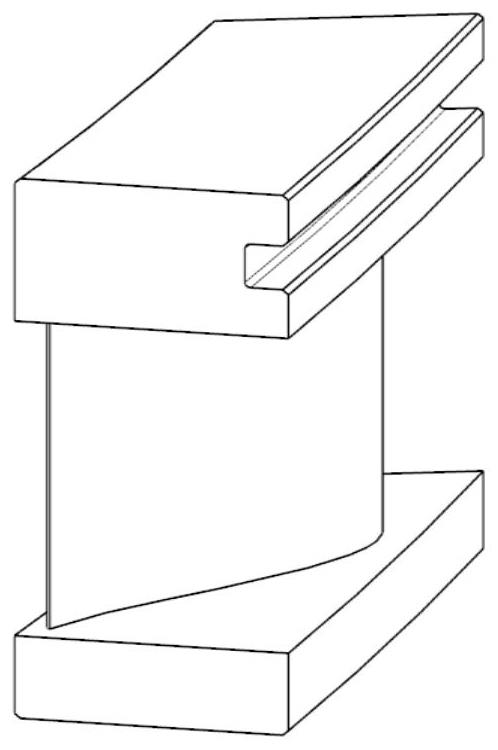

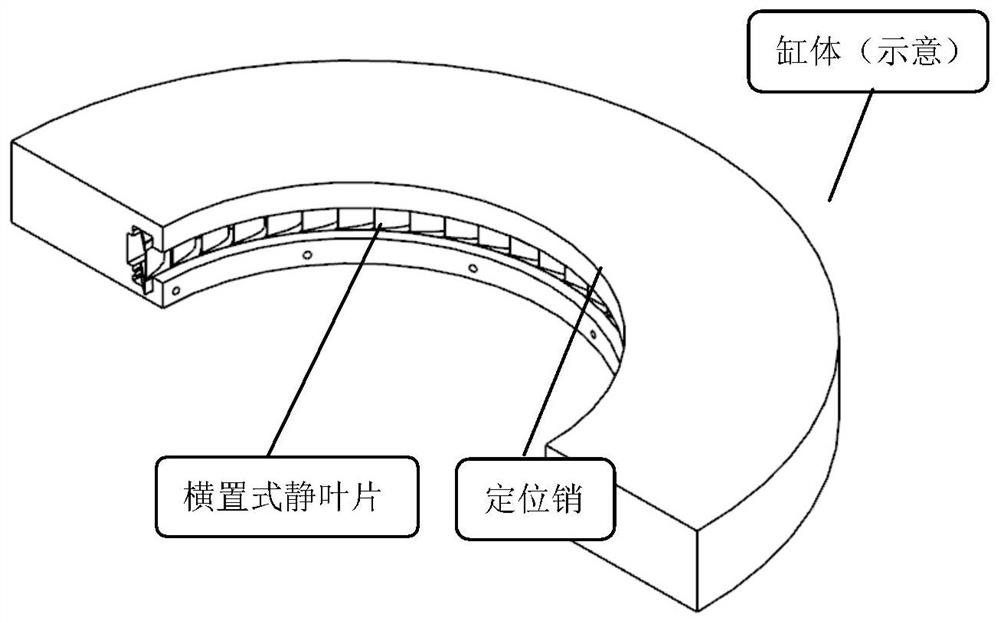

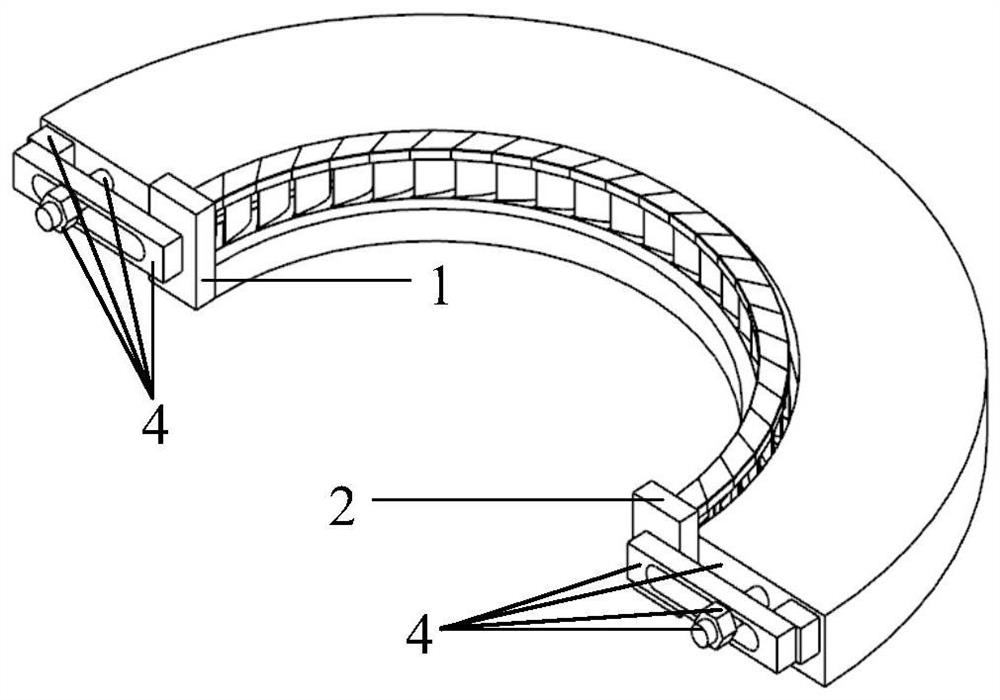

[0029] Firstly, the positioning tool used in the assembly of horizontal stationary blades is introduced

[0030] Technical conditions:

[0031] (1) Conditions of use of the positioning tool for horizontally mounted stationary blades

[0032] It is suitable for positioning and fixing the stator blades during the assembly process of the horizontal stator blades.

[0033] (2) Design requirements for positioning tooling for horizontal stationary blades

[0034] In order to ensure the reasonable design and reliable operation of the horizontal stationary blade positioning tool, the tool must meet the following requirements:

[0035] 1) It can accurately ensure the position of the stator blade in the installation groove, and effectively play a positioning role;

[0036] 2) The half-circumferential stationary blade can be fixed in the installation groove to meet the processing requirements of the subsequent positioning pin hole;

[0037] 3) The structure is simple, the operation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com