Core for a housing of a valve and method for producing said core

A core and shell technology, which is applied in the field of processing the core and casting and forming the core, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

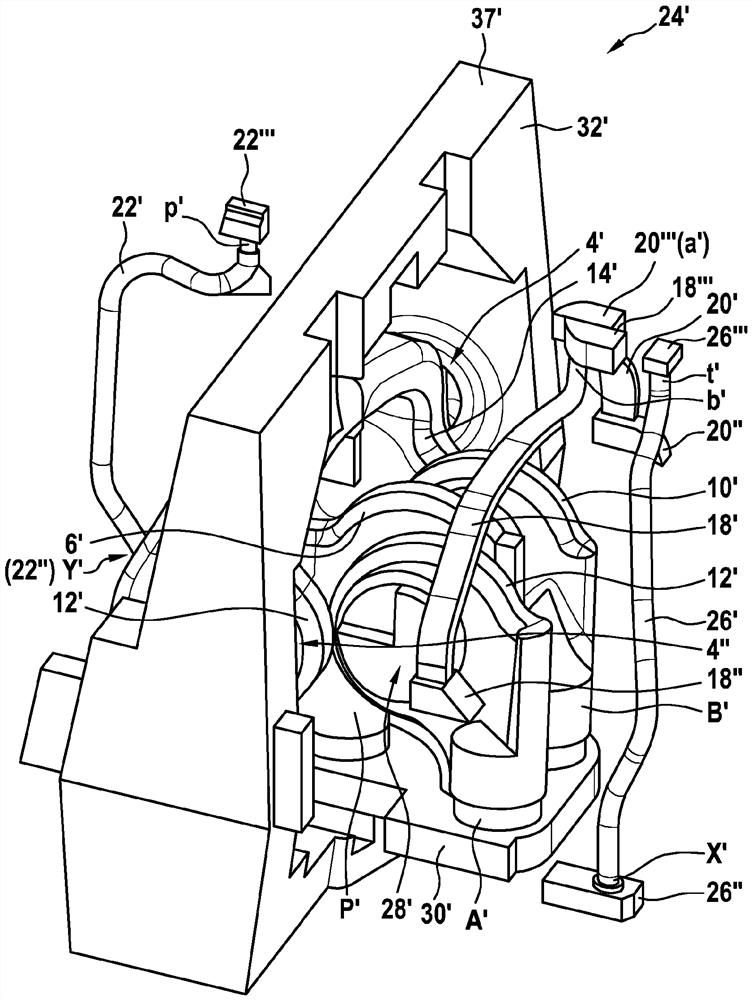

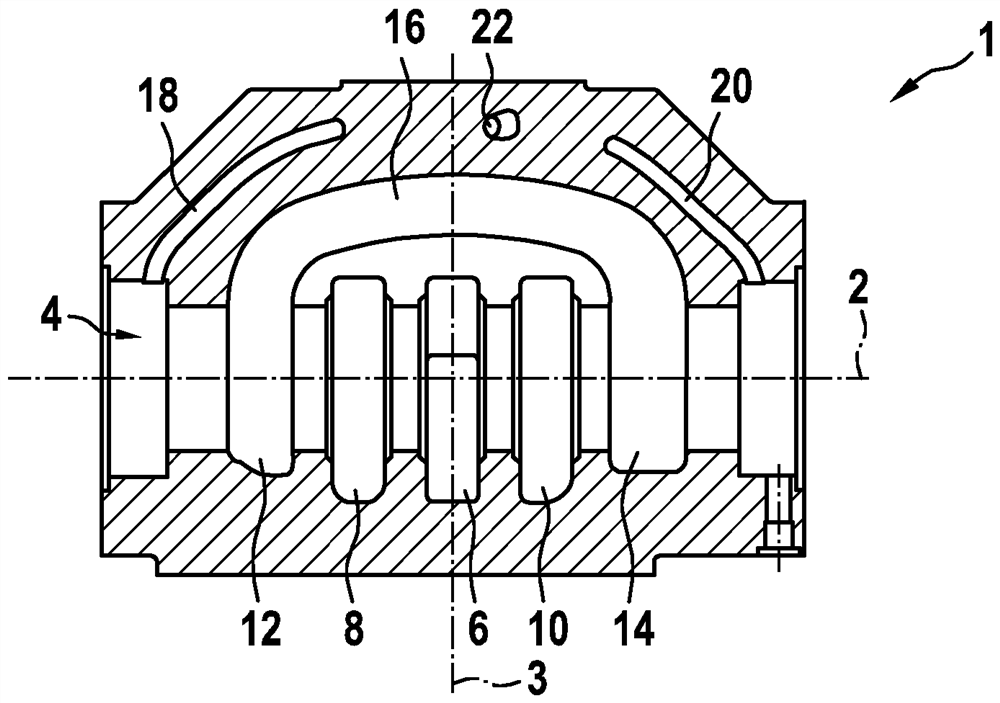

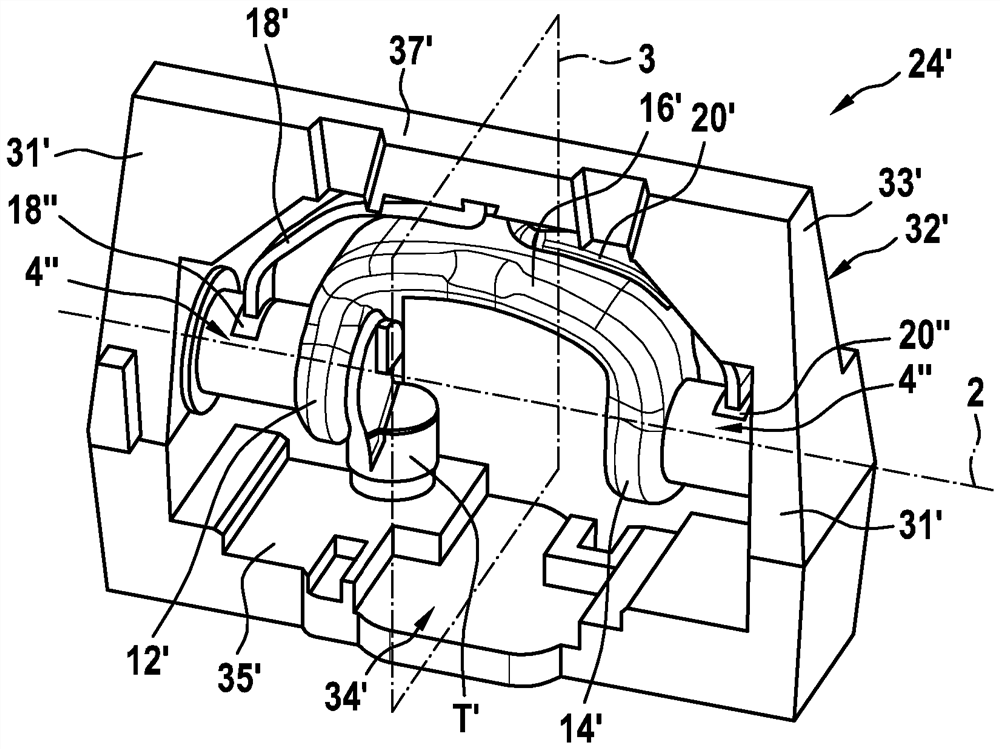

[0045] figure 1 Shown is a housing 1 produced according to the invention for a valve designed in the form of a slide, which is cast by means of a core according to the invention which is designed in multiple parts. All of the cores are shown here figure 1 Pressure chambers or pressure medium passages drawn unshaded in . These are: a recess 4 extending in the direction of the longitudinal axis 2, in which a valve body for controlling the pressure medium connection can be accommodated in a longitudinally displaceable manner; a high-pressure chamber 6, which is connected to the pressure medium The source, in particular the pump connection (not shown) of the housing 1 is connected to the pressure medium; the two working pressure chambers 8 , 10 are connected to the corresponding working connection (not shown) of the housing 1 in the pressure medium In connection; two low-pressure pressure chambers or storage tank pressure chambers 12, 14, which are connected by a snap-shaped con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com