Design, construction and debugging of efficient and controllable online microwave reaction system

A microwave reaction system and microwave reaction technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of wide distribution of product composition, inability to accurately reflect the microwave cracking reaction characteristics of biomass, and complexity. Achieve simple structure, improve work efficiency and flexibility, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

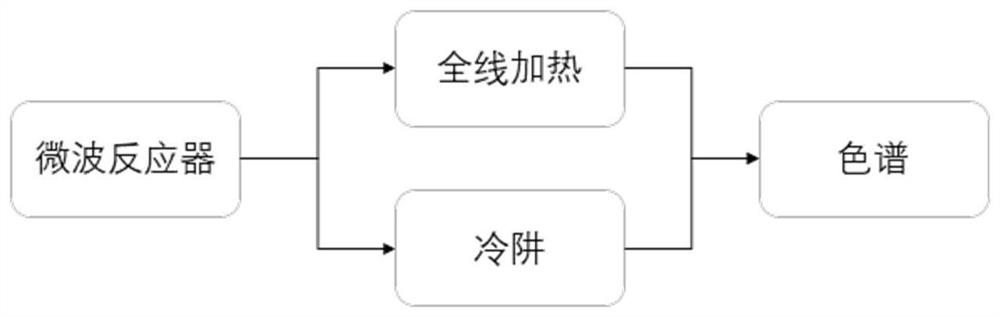

[0046] An efficient and controllable online microwave reaction system, such as figure 1 As shown, it includes a microwave reaction unit, a double gas circuit unit and a gas chromatographic analysis unit connected in sequence;

[0047] The dual gas circuit unit includes a parallel full-line heating gas circuit and a cold trap liquefied gas circuit;

[0048] The microwave reaction unit is connected to the whole heating gas circuit and the cold trap liquefied gas circuit through a first pipeline with a diverting valve;

[0049] The gas chromatographic analysis unit is connected with the whole heating gas circuit and the cold trap liquefied gas circuit through a second pipeline with a steering valve.

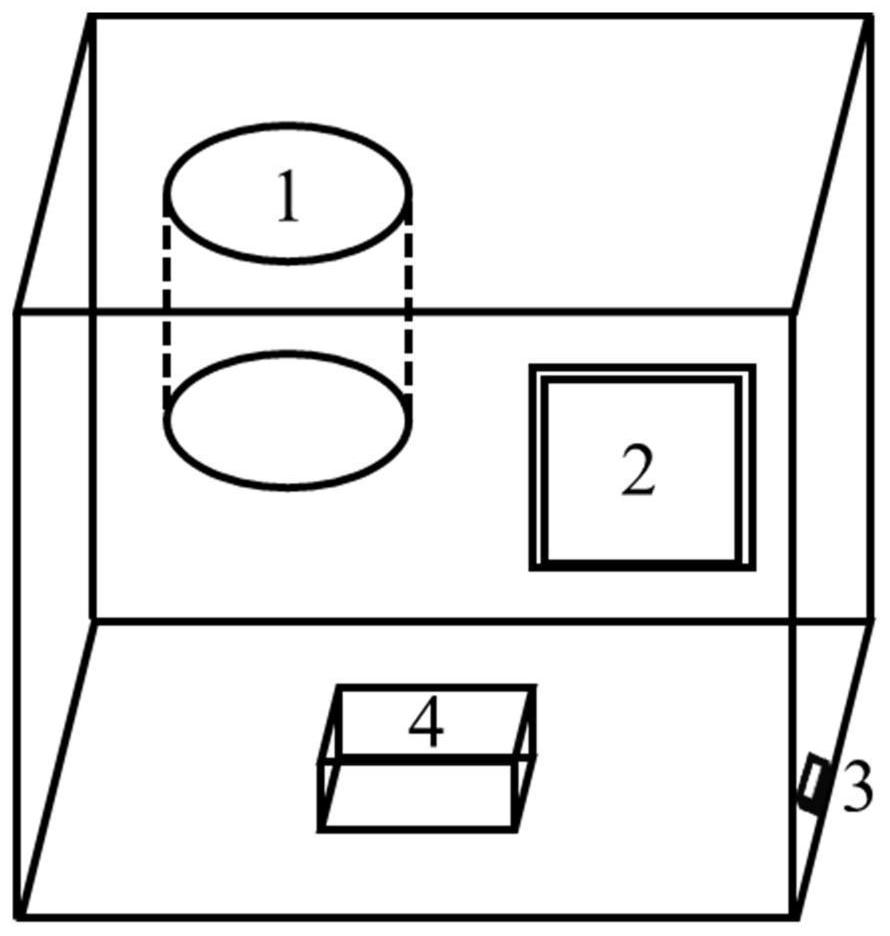

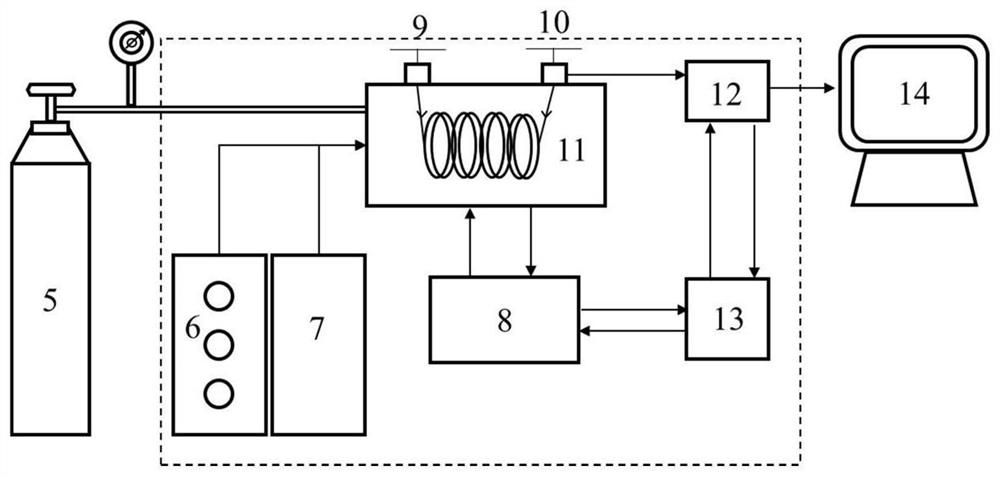

[0050] The microwave reaction unit: as figure 2 As shown, it includes a chamber 1, a microwave generator 4, a shielding device and a PLC intelligent control system; the chamber is equipped with a temperature detection device, an input power monitoring device, and a reflected powe...

Embodiment 2

[0059] Taking microwave pyrolysis of carbonaceous materials as an example, using the microwave reaction system described in Example 1 to carry out pyrolysis treatment, and analyzing the products generated by the reaction, the steps are as follows:

[0060] According to the requirements, microwave-assisted pyrolysis of carbonaceous materials is carried out after controlling the microwave power and reaction temperature;

[0061] At any time during the reaction, real-time chromatographic online analysis of the generated products can be performed, and the full-line heating circuit and cold trap circuit can be switched at any time to conduct transient analysis of all components of products with different boiling points (C1-C5 and above C6 components) and transient analysis of low boiling point products (C1-C5).

[0062] During the reaction process, turn the valve to the full-line heating gas path, heat the product to maintain the gas state and enter the chromatogram for full compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com