Clamp, clutch test equipment and clutch test method

A technology for testing equipment and clutches, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., and can solve the problems of low disassembly and replacement efficiency, poor compatibility, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] With the improvement of machining technology, the application of clutch 700 in various instrument and equipment fields is becoming more and more extensive. Clutch 700 is a common component in mechanical transmission, which can separate or engage the transmission system at any time. The basic requirements are: smooth joint, rapid and thorough separation; convenient adjustment and repair; small external size; small mass; good wear resistance and sufficient heat dissipation capacity; Two types of friction. In order to ensure that the clutch 700 is running stably, testing the clutch 700 is an essential step.

[0068] This embodiment provides a fixture, through which the clutch 700 is fixed, and installed on the driving member, and the driving member is used to drive the fixture loaded with the clutch 700 to rotate at a high speed, and then the durability test of the clutch 700 is carried out so that the clutch 700 meets Use performance.

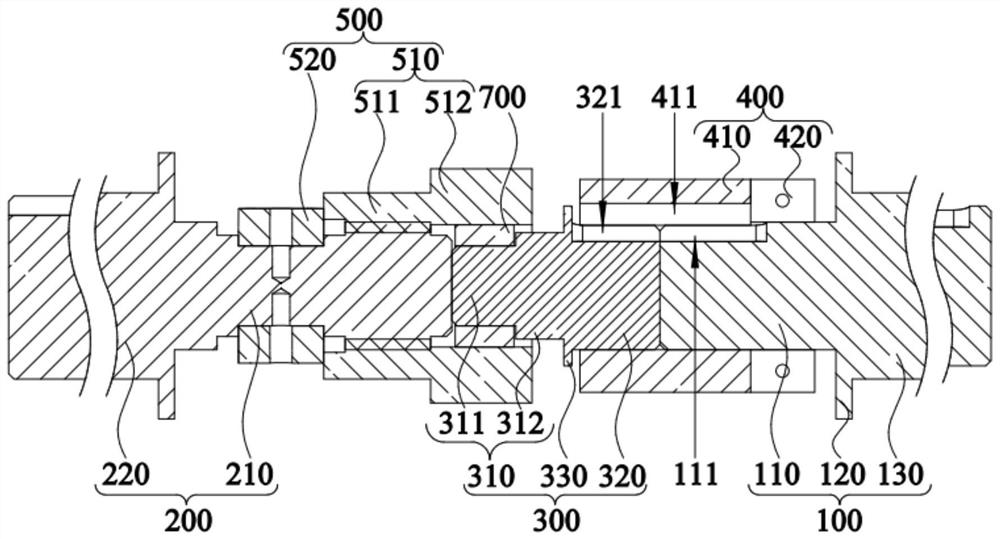

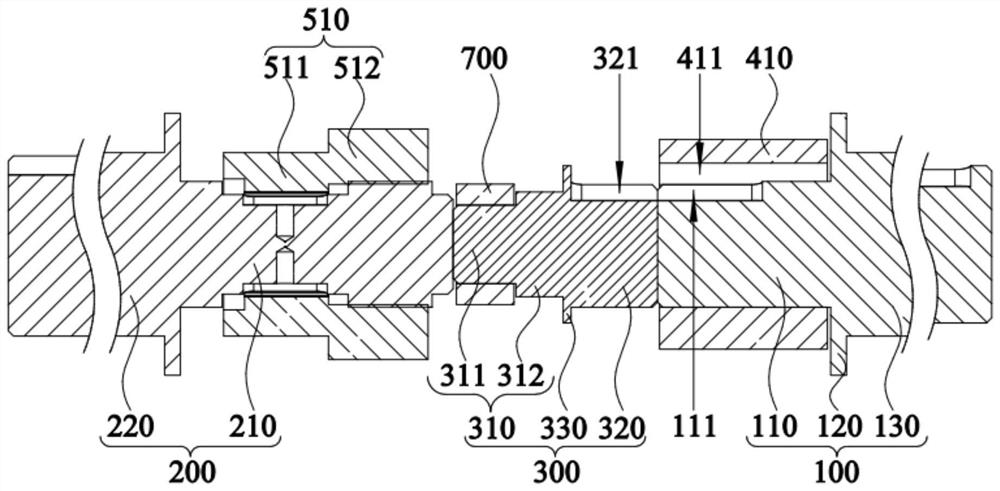

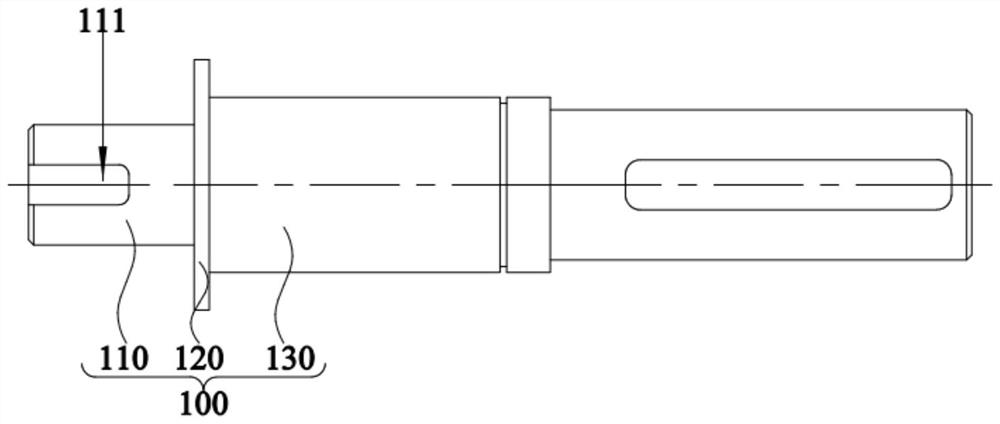

[0069] like figure 1 and figu...

Embodiment 2

[0096] This embodiment provides a clutch testing method. Through the above fixture, the assembly steps of the clutch 700 before testing are as follows:

[0097] The first fixing assembly 400 is sleeved on the driving shaft 100 and positioned at the second position, and the second fixing assembly 500 is sleeved on the driven shaft 200 and positioned at the fourth position;

[0098] The clutch 700 is sleeved on the installation shaft 300;

[0099] Slide the first fixing component 400 to the first position to connect and fix the installation shaft 300 with the driving shaft 100;

[0100] sliding the second fixing assembly 500 to the third position to connect and fix the mounting shaft 300 with the driven shaft 200; and

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com