High-weather-resistant heat-conducting photovoltaic gap film and preparation method thereof

A gap, photovoltaic technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of poor weather resistance of reflective films and high local temperature of cells, and achieve good thermal conductivity, improved service life, and good reflectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

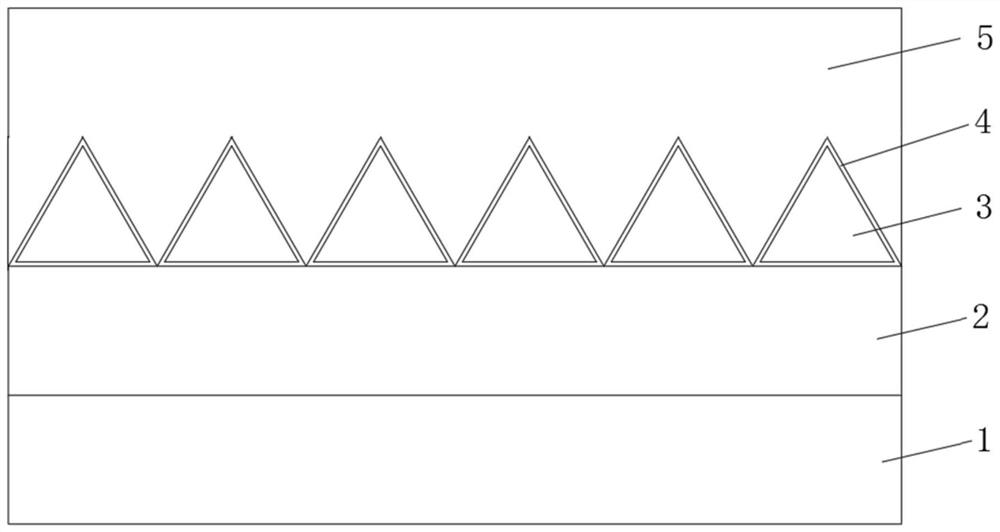

[0027] Such as figure 1 As shown, a highly weather-resistant and thermally conductive photovoltaic gap reflective film has a five-layer structure from bottom to top, an adhesive layer 1, a weather-resistant carrier layer 2, a prism layer 3, a reflective layer 4, and a heat-conducting layer 5. The thickness of the adhesive layer 1 is 50 μm; the thickness of the weather-resistant carrier layer 2 is 80 μm; the height from the bottom line to the edge of the prism layer 3 is 30 μm; the thickness of the reflective layer 4 is 70 nm; the thickness of the heat conduction layer 5 is 95 μm.

[0028] The method for making the above-mentioned gap film for high weather resistance and heat conduction photovoltaics includes:

[0029] (1) A plurality of prism structures are pre-prepared on the surface of the pressure roller, and then the surface of the weather-resistant carrier layer 2 is coated with a UV-curable adhesive resin and passed through the pressure roller. On the weather-resistant...

Embodiment 2

[0036] Such as figure 1 As shown, a highly weather-resistant and thermally conductive photovoltaic gap reflective film has a five-layer structure from bottom to top, an adhesive layer 1, a weather-resistant carrier layer 2, a prism layer 3, a reflective layer 4, and a heat-conducting layer 5. The thickness of the adhesive layer 1 is 10 μm; the thickness of the weather-resistant carrier layer 2 is 60 μm; the height from the bottom line to the edge of the prism layer 3 is 25 μm; the thickness of the reflective layer 4 is 70 nm; the thickness of the heat conduction layer 5 is 70 μm.

[0037] The method for making the above-mentioned gap film for high weather resistance and heat conduction photovoltaics includes:

[0038] (1) A plurality of prism structures are pre-prepared on the surface of the pressure roller, and then the surface of the weather-resistant carrier layer 2 is coated with a UV-curable adhesive resin and passed through the pressure roller. On the weather-resistant...

Embodiment 3

[0045] Such as figure 1 As shown, a highly weather-resistant and thermally conductive photovoltaic gap reflective film has a five-layer structure from bottom to top, an adhesive layer 1, a weather-resistant carrier layer 2, a prism layer 3, a reflective layer 4, and a heat-conducting layer 5. The thickness of the adhesive layer 1 is 80 μm; the thickness of the weather-resistant carrier layer 2 is 100 μm; the height from the bottom line to the edge of the prism layer 3 is 50 μm; the thickness of the reflective layer 4 is 100 nm; the thickness of the heat conduction layer 5 is 100 μm.

[0046] The method for making the above-mentioned gap film for high weather resistance and heat conduction photovoltaics includes:

[0047] (1) A plurality of prism structures are pre-prepared on the surface of the pressure roller, and then the surface of the weather-resistant carrier layer 2 is coated with a UV-curable adhesive resin and passed through the pressure roller. On the weather-resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com