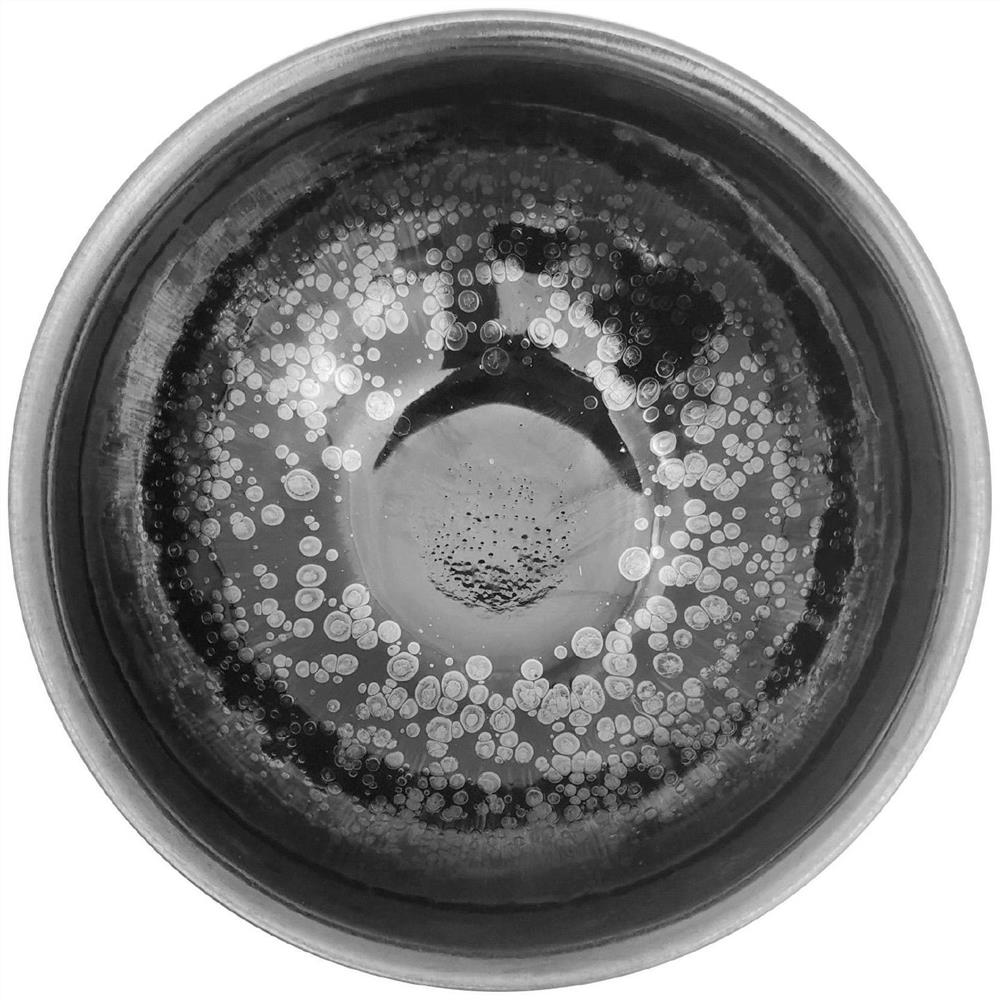

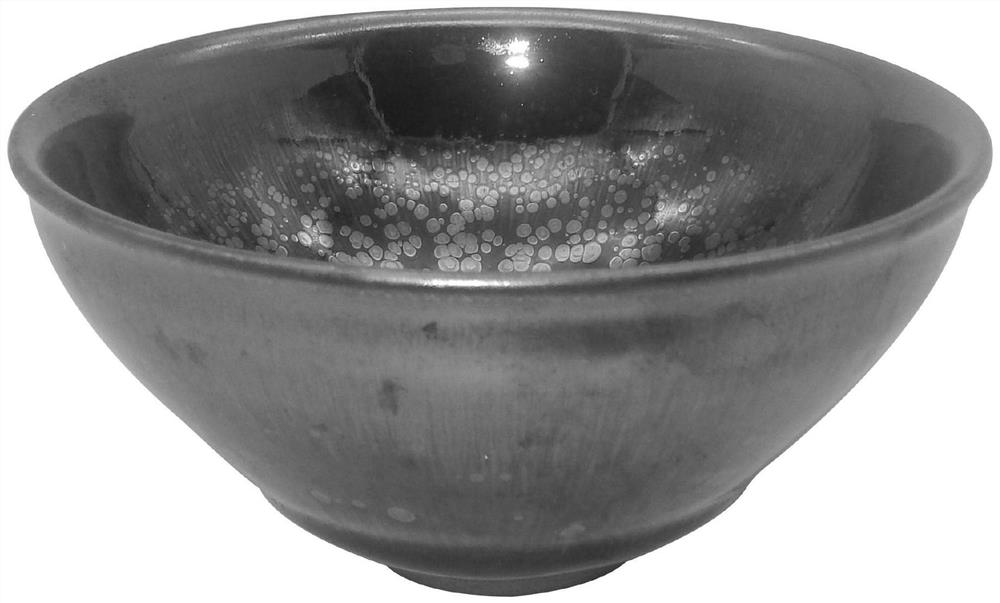

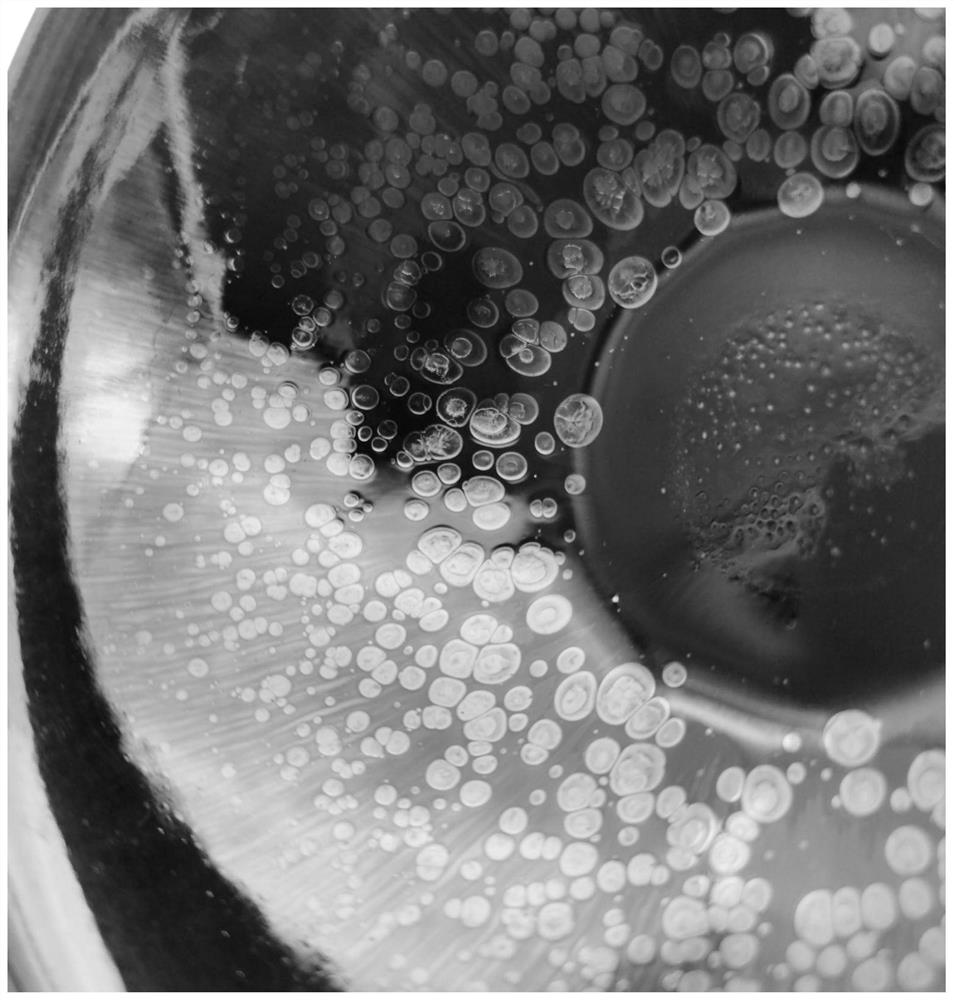

In-glaze jellyfish drop building cup

A technology of jellyfish and glaze slurry, which is applied in the field of jellyfish dripping in glaze, can solve the problem of reducing the art, collection and economic value of Jianzhan, it is difficult to master the recipe of Jianzhang, the selection of firing atmosphere and temperature, and the difficulty of firing Jianzhan advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] (1) Preparation of green body;

[0071] Mix 1.5-2.5 parts by weight of laterite and 7-9 parts by weight of kaolin, pulverize, wash with water, pass through a 80-120 mesh sieve, press filter, smelt, and stale to obtain the mud; throw the mud Shaping, trimming, bisque firing at 860-900°C for 5-7h, taking out to obtain the green body;

[0072] (2) preparation of plant ash;

[0073] 2-3 parts by weight of pine and 3-5 parts by weight of elm are mixed, burned, and ashes are collected to obtain plant ash;

[0074] (3) Preparation of main body glaze slurry and mouth edge glaze slurry;

[0075] The main body glaze slurry is prepared by the following method: 380-420 parts by weight of glaze stone, 45-55 parts by weight of plant ash, 30-40 parts by weight of iron red, 45-55 parts by weight of potassium feldspar, 45-55 parts by weight Grinding the albite feldspar and 560-600 parts by weight of water, and passing through a 100-140 mesh sieve to obtain the main glaze slurry;

[...

Embodiment 1

[0115] Example 1 jellyfish drop in glaze to build a cup

[0116] The preparation process of jellyfish in glaze drip Jianzhan includes steps:

[0117] (1) Preparation of green body;

[0118] Mix 2 parts by weight of red clay and 8 parts by weight of kaolin, pulverize, wash with water, pass through a 100-mesh sieve, press filter, smelt, and stale to obtain the mud; pull the mud into shape, repair the billet, and Biscuit firing at 880°C for 6h, then take out to obtain green body.

[0119] (2) preparation of plant ash;

[0120] 2.5 parts by weight of sun-dried pine and 4 parts by weight of sun-dried elm are mixed, burned, and ashes are collected to obtain plant ash.

[0121] (3) Preparation of main body glaze slurry and mouth edge glaze slurry;

[0122] The main body glaze slurry is prepared by the following method: 400 parts by weight of glaze stone, 50 parts by weight of plant ash, 36 parts by weight of iron red, 50 parts by weight of potassium feldspar, 50 parts by weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com