Large-moisture desulfurization gypsum stable feeding and metering system

The technology of desulfurization gypsum and metering system is applied in the field of blanking system, which can solve the problem that a storage cylinder cannot perform stable blanking, and achieve the effects of ensuring blanking speed, improving blanking precision control, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

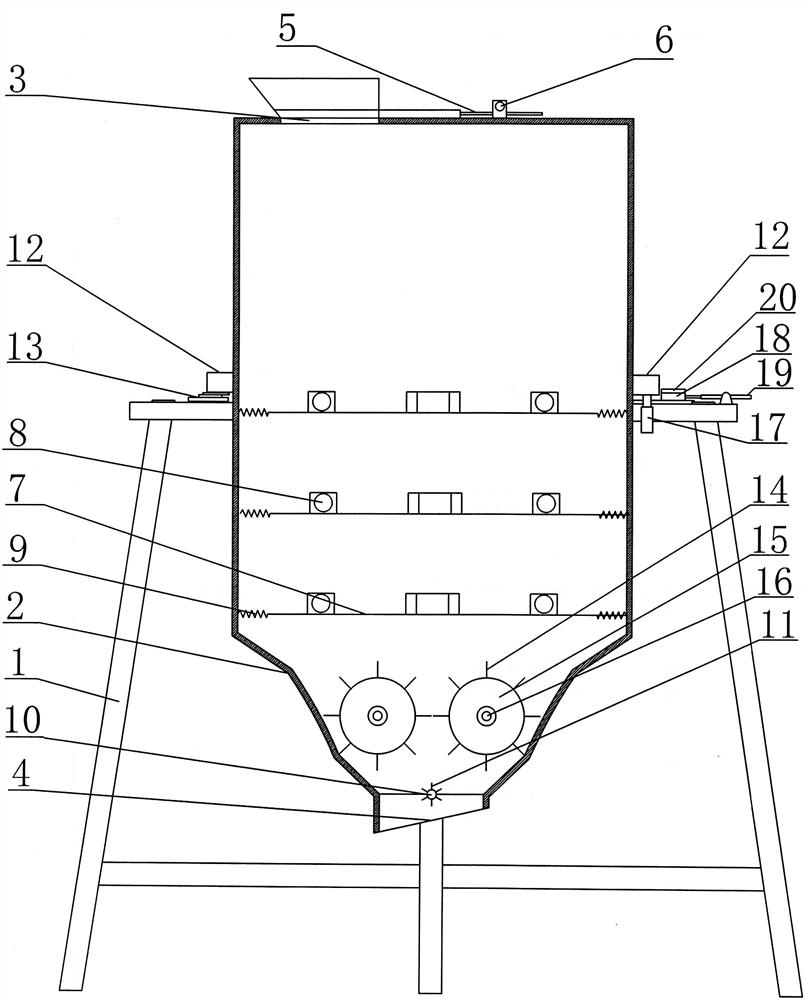

[0019] Such as figure 1 The embodiment of the present invention shown comprises: support 1, and support 1 is provided with material storage cylinder 2, and material storage cylinder 2 is provided with feed inlet 3 and discharge outlet 4, and feed inlet 3 is provided with feed door, and feed The door is connected to the feeding door driving device, and the feeding door driving device includes: a screw rod 5, which is connected to the feeding door driving motor 6, and both sides of the feeding door are located in the guide groove. The feed door is also equipped with a feed door switch, which is used to control the opening or closing of the feed door. When feeding, the feed door switch can be manually opened to open the feed door through the feed door motor. When the feeding is finished, the feed door switch can be closed manually so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com