Color changing process for PE regenerated particles with excellent performance

An excellent, granular technology, applied in the field of PE materials, can solve the problems of unfavorable waste and old PE recycled particles, poor mechanical properties, and low product purity, and achieve the effects of enhancing mechanical properties, improving impact resistance and toughness, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

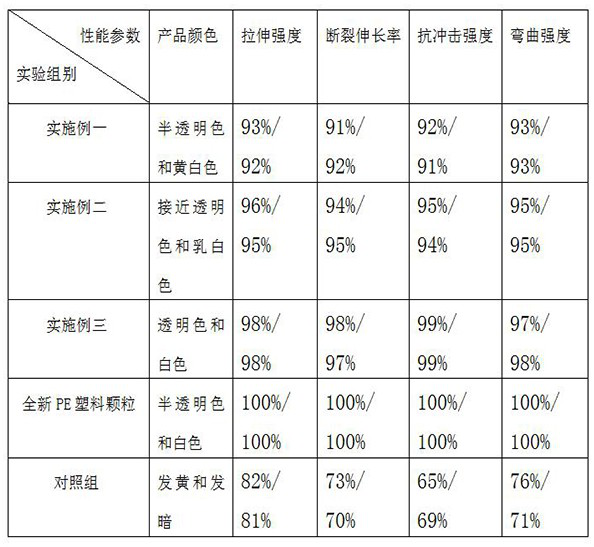

Embodiment 1

[0016] A process for changing the color of PE recycled particles with excellent performance, including the following steps: S1, sorting and crushing: sorting and crushing the recovered PE plastic products through a semi-automatic sorting line and a crusher; S2, washing and soaking: putting the obtained PE plastic products in S1 Wash in the bleaching pool, the water temperature is 35°C, the soaking time is 4h, then take it out and put it into the friction cleaning machine for secondary water washing, and sprinkle the cleaning agent in the friction cleaning machine, wherein the cleaning agent includes the following in terms of parts by mass Components: 4 parts of sodium hydroxide, 3 parts of decontamination powder and 1 part of disinfectant; S3, drying: put the obtained product of S2 into a spin dryer to dry at a speed of 250r / min; S4, color sorting: use color The selection machine divides the obtained area of S3 into PE transparent material and PE other color materials; S5, gr...

Embodiment 2

[0018] A process for changing the color of PE recycled particles with excellent performance, including the following steps: S1, sorting and crushing: sorting and crushing the recovered PE plastic products through a semi-automatic sorting line and a crusher; S2, washing and soaking: putting the obtained PE plastic products in S1 Wash in the bleaching pool, the water temperature is 36.5°C, the soaking time is 4.5h, then take it out and put it into the friction cleaning machine for secondary water washing, and sprinkle the cleaning agent in the friction cleaning machine, wherein the cleaning agent includes The following components: 5 parts of sodium hydroxide, 5 parts of decontamination powder and 2 parts of disinfectant; S3, drying: put the obtained product of S2 into the drying machine to dry, and the speed of the drying machine is 275r / min; S4, color selection: use The color sorter divides the obtained area of S3 into PE transparent material and other PE color materials; S5, ...

Embodiment 3

[0020] A process for changing the color of PE recycled particles with excellent performance, including the following steps: S1, sorting and crushing: sorting and crushing the recovered PE plastic products through a semi-automatic sorting line and a crusher; S2, washing and soaking: putting the obtained PE plastic products in S1 Wash in the bleaching pool, the water temperature is 38°C, the soaking time is 5h, then take it out and put it into the friction cleaning machine for secondary water washing, and sprinkle the cleaning agent in the friction cleaning machine, wherein the cleaning agent includes the following in terms of parts by mass Components: 6 parts of sodium hydroxide, 4 parts of decontamination powder and 3 parts of disinfectant; S3, drying: put the obtained product of S2 into the drying machine to dry, and the speed of the drying machine is 300r / min; S4, color sorting: use color The selection machine divides the obtained area of S3 into PE transparent material and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com