Single crystal material pole diagram pole calibration method based on orientation distribution function

A technology of distribution functions and single crystal materials, which is applied to the analysis of materials, material analysis using wave/particle radiation, and complex mathematical operations. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

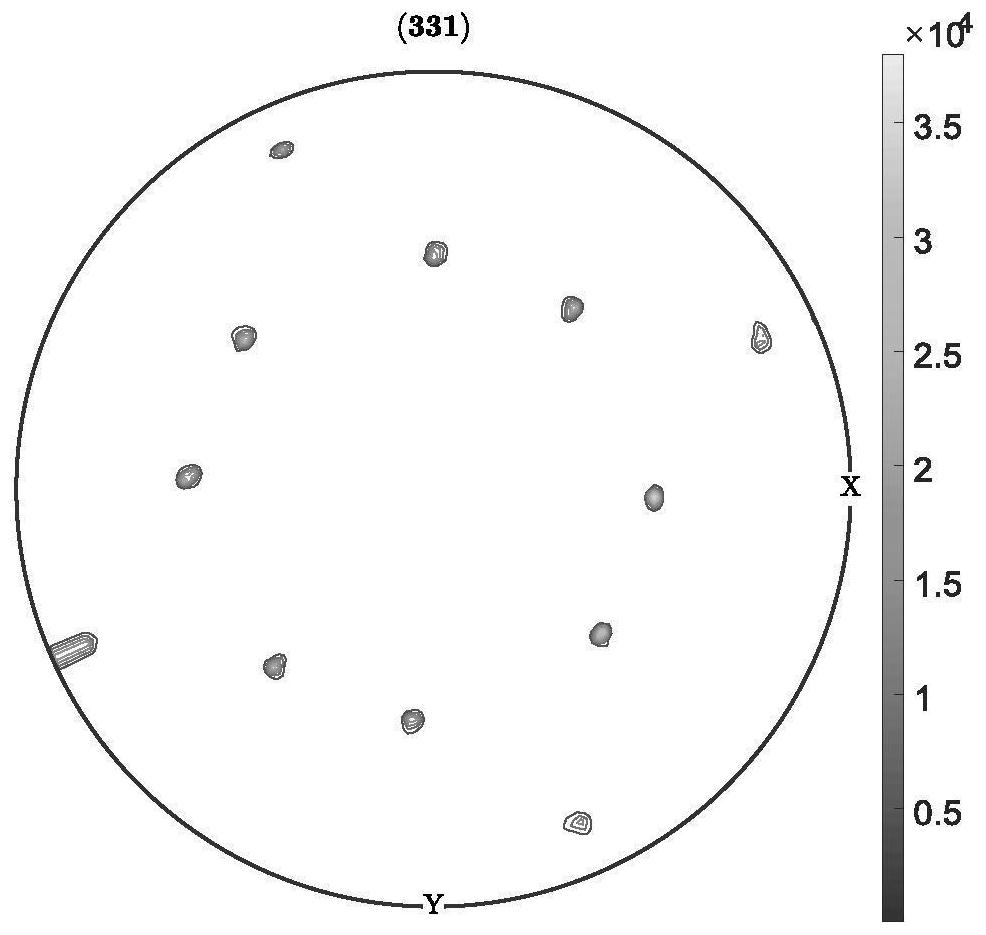

[0055] (1) Put the prepared sample in X-ray diffraction or more, and the test range of 0 to 70 °, the test interval is 2 °, the ψ angle test range 0 ~ 360 ° test interval is 2 °, Take 0.1s of the count time, see attachment figure 1 ;

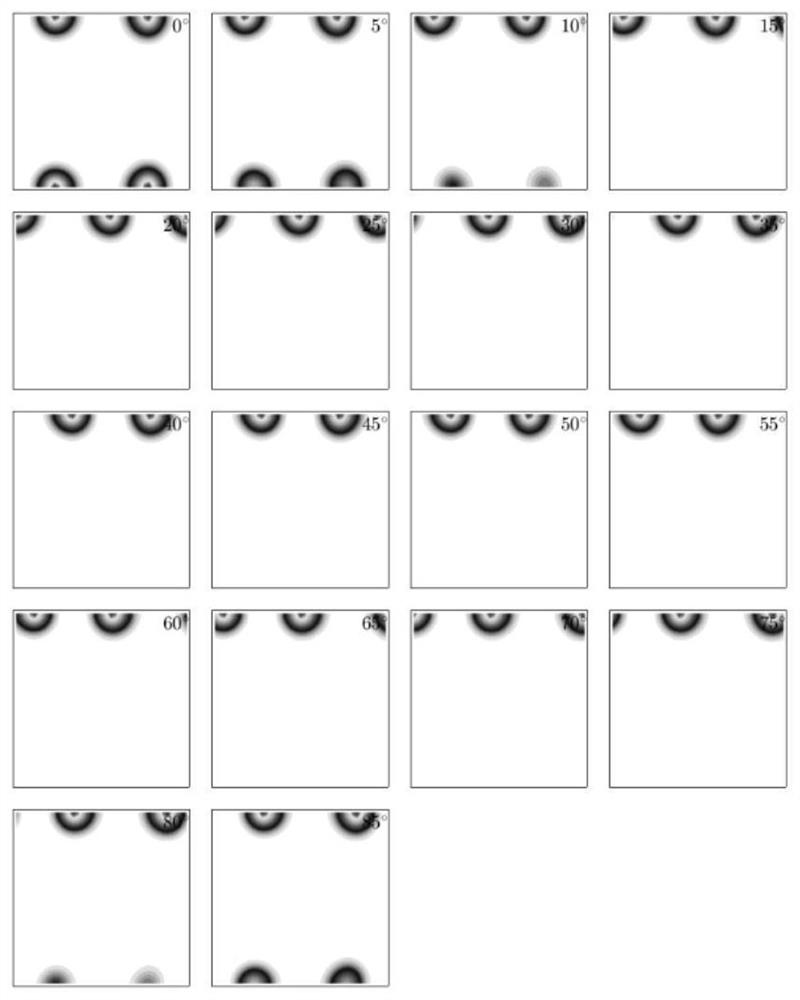

[0056] (2) The material obtained by testing step 1) is measured by the primary map using the Bangure function to calculate the orientation distribution function of the material of 0.1 °.figure 2 ;

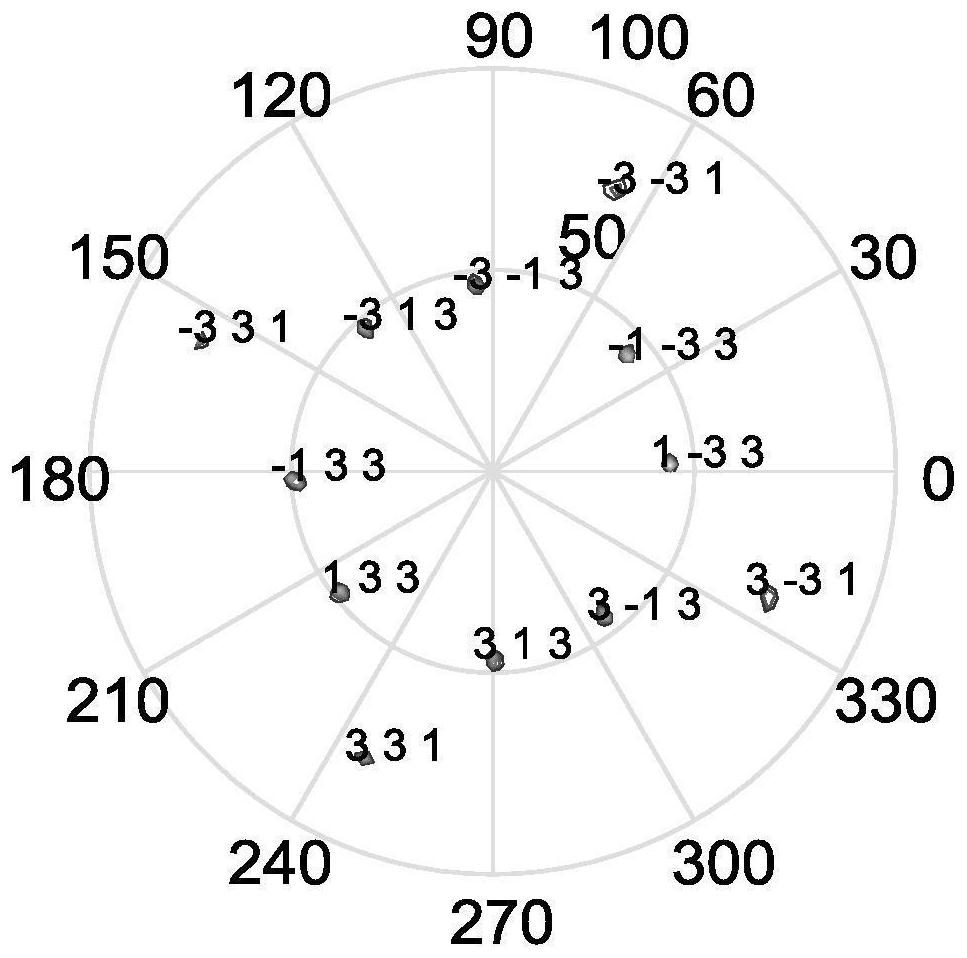

[0057] (3) Using Step 2) The resulting orientation distribution function is calculated, calculate the pole position of each crystal surface of the theoretical position, and corresponding to the measured pole map, complete the calibration of the polar map, see attachment image 3 .

Embodiment 2

[0059] (1) Put the prepared sample in X-ray diffraction or more, and the test range of 0 to 70 °, the test interval is 2 °, the ψ angle test range 0 ~ 360 ° test interval is 2 °, Take 0.1s of the count time, see attachment Figure 4 ;

[0060] (2) The material obtained by testing step 1) is measured by the primary map using the Bangure function to calculate the orientation distribution function of the material of 0.1 °. Figure 5 ;

[0061] (3) Using Step 2) The resulting orientation distribution function is calculated, calculate the pole position of each crystal surface of the theoretical position, and corresponding to the measured pole map, complete the calibration of the polar map, see attachment Image 6 .

Embodiment 3

[0063] (1) Put the prepared sample in X-ray diffraction or more, and the test range of 0 to 70 °, the test interval is 2 °, the ψ angle test range 0 ~ 360 ° test interval is 2 °, Take 0.1s of the count time, see attachment Figure 7 ;

[0064] (2) The material obtained by testing step 1) is measured by the primary map using the Bangure function to calculate the orientation distribution function of the material of 0.1 °. Figure 8 ;

[0065] (3) Using Step 2) The resulting orientation distribution function is calculated, calculate the pole position of each crystal surface of the theoretical position, and corresponding to the measured pole map, complete the calibration of the polar map, see attachment Figure 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com