Short thread end cutting device of column type sewing machine

A sewing machine and short thread technology, which is applied to the thread cutting mechanism, sewing machine components, sewing equipment and other directions in the sewing machine, can solve the problems that the feeding column does not have the collection function, and the debris affects the normal thread cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

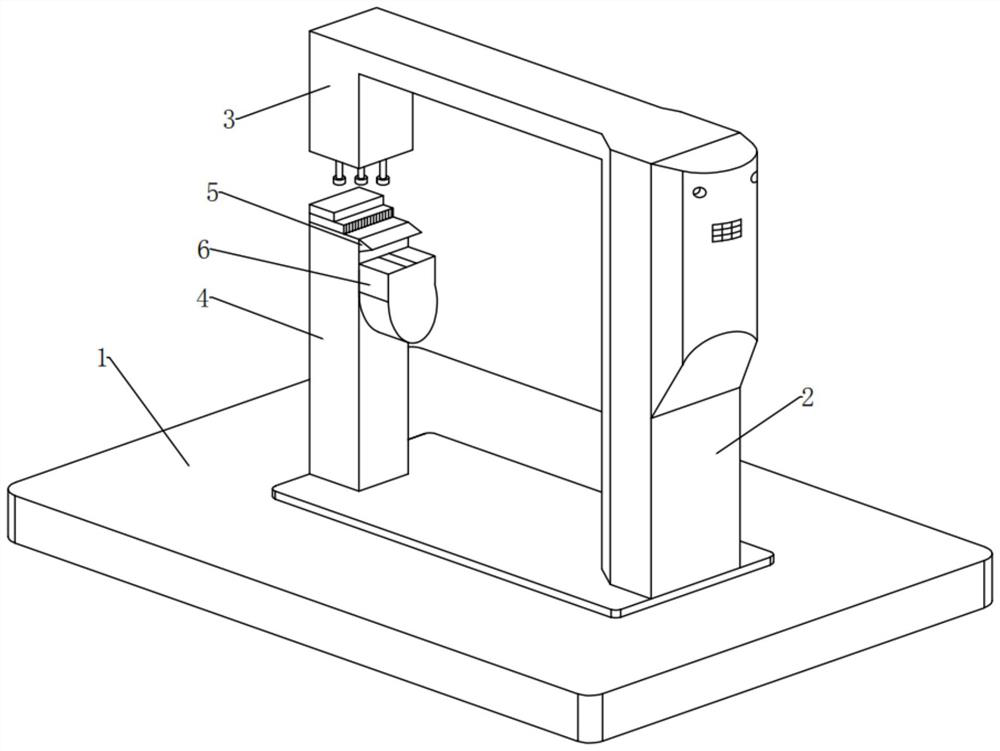

[0043] see Figure 1-2 , in an embodiment of the present invention, a short thread trimming device for a pillar sewing machine, comprising:

[0044] Base 1, a sewing machine main body 2 is fixedly installed on the top front of the base 1, a sewing machine head 3 is fixedly installed on the top rear of the sewing machine main body 1, a feeding column 4 is fixedly installed on the top rear of the base 1, and a feeding column 4 A cutter 5 is fixedly installed at the top position of the front side outer surface;

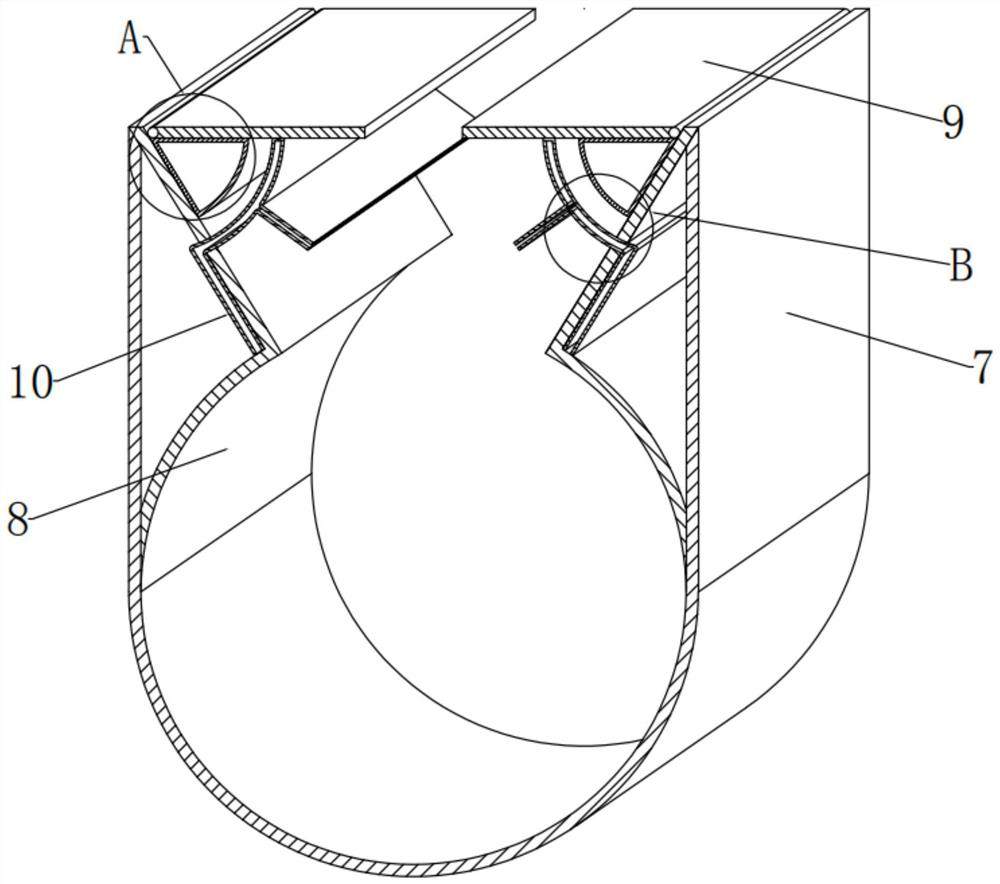

[0045] The collection assembly 6, the front outer upper end of the feeding column 4 is located directly below the cutter 5 and is fixedly equipped with a collection assembly 6 that can collect thread ends and rags. The collection assembly 6 includes: a collection shell 7, a folding plate 8, which can be controlled A material control assembly 9 for thread end rags to enter and exit and a material guide assembly 10 that can lead out the material wetted by thread end rags;...

Embodiment 2

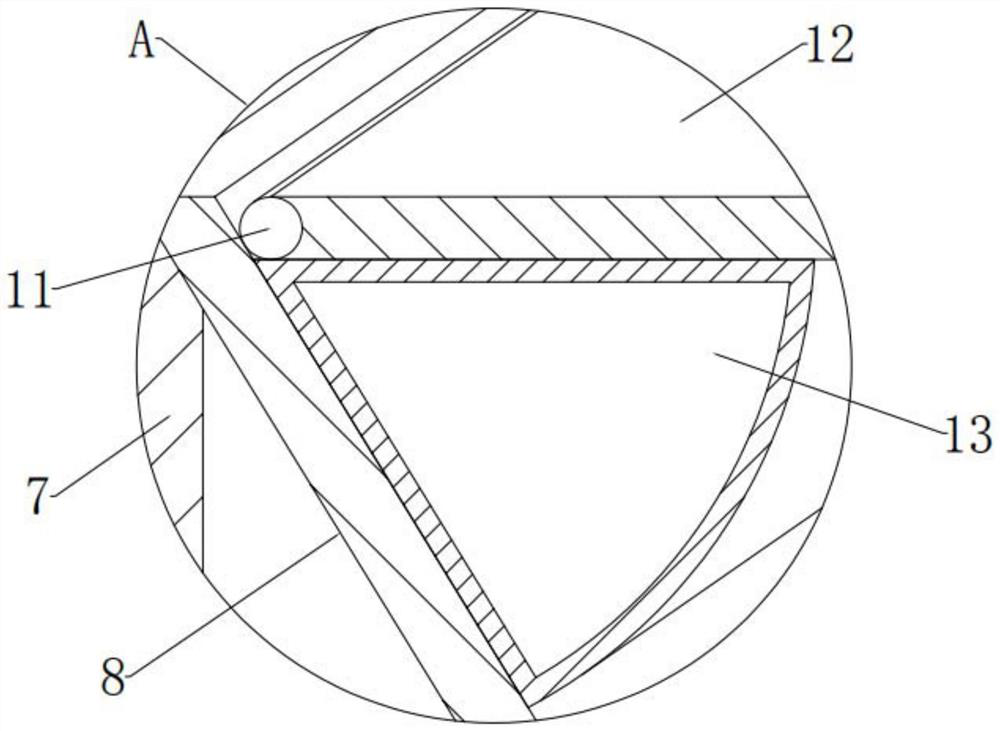

[0059] see Figure 2-3 with Figure 5-6 , the embodiment of the present invention is different from embodiment 1 in that: the material control assembly 9 includes:

[0060] Rotating shaft 11, the left and right parts of the inner top of the collecting shell 7 are located at the top of the outer surface of the folding plate 8, and the rotating shaft 11 is installed in the front and rear horizontal direction. Location;

[0061] The rotating shaft 11 here is for the convenience of when the rags fall into the left and right ends of the top opening of the collection shell 7, it can be used as a carrier for the rotation and discharge of the rotating plate 12 at the left and right ends.

[0062] In the embodiment of the present invention, the material control assembly 9 also includes:

[0063] Turning plate 12, one side outer surface of rotating shaft 11 is surrounded and fixedly installed with turning plate 12, and turning plate 12 is in horizontal static equilibrium state under ...

Embodiment 3

[0070] see figure 2 with Figure 4-6 Compared with Embodiment 1, the embodiment of the present invention differs in that: the material guide assembly 10 includes:

[0071] Material storage tank, the inboard side of folding plate 8 and the inwall of collecting shell 7 to the top are combined to open with material storage tank. Clean water is pre-installed in the internal position of the tank, and the pre-installed amount of clean water is 2 / 3 of the internal space of the storage tank. The long through hole of the folding plate 8 is provided with an inner end inlet and an outer end outlet in the material storage tank;

[0072] The material storage tank here is set as a triangular shape with a concave bottom on a longitudinal section, which is to facilitate the storage of wet materials composed of clear water, so that the clear water can be exported when the material guide tank 14 is active in it; And the preloaded portion of clear water is 2 / 3 of the internal space of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com