A pasta automatic conveying and placing machine

An automatic conveying and plate-setting machine technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large cost investment and low efficiency, and achieve the effect of good shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

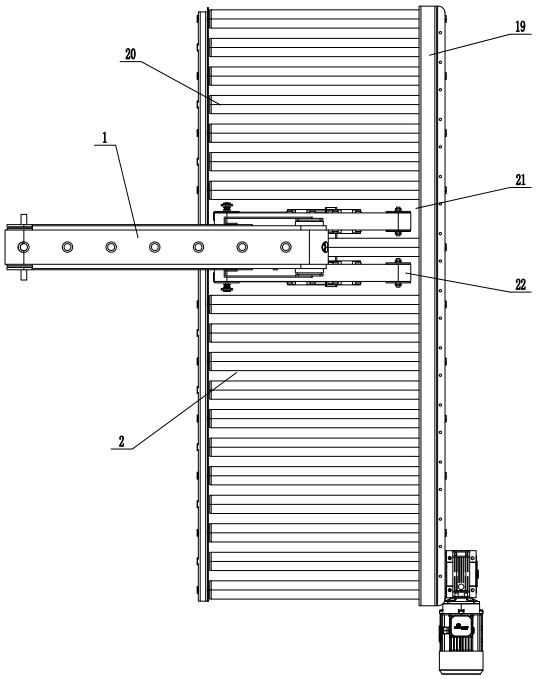

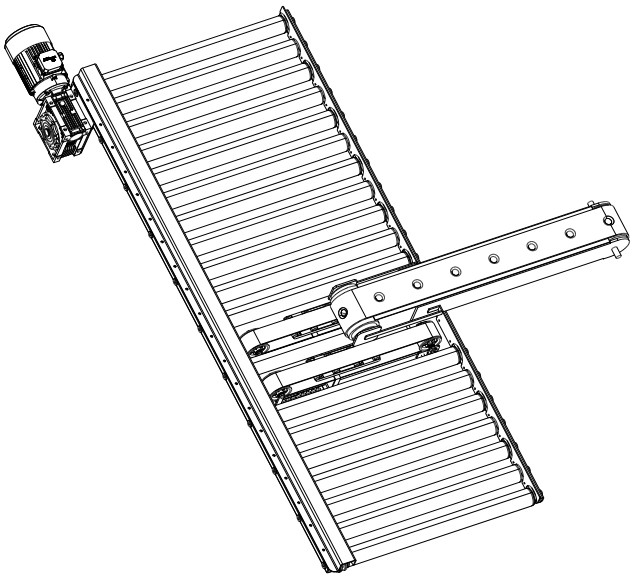

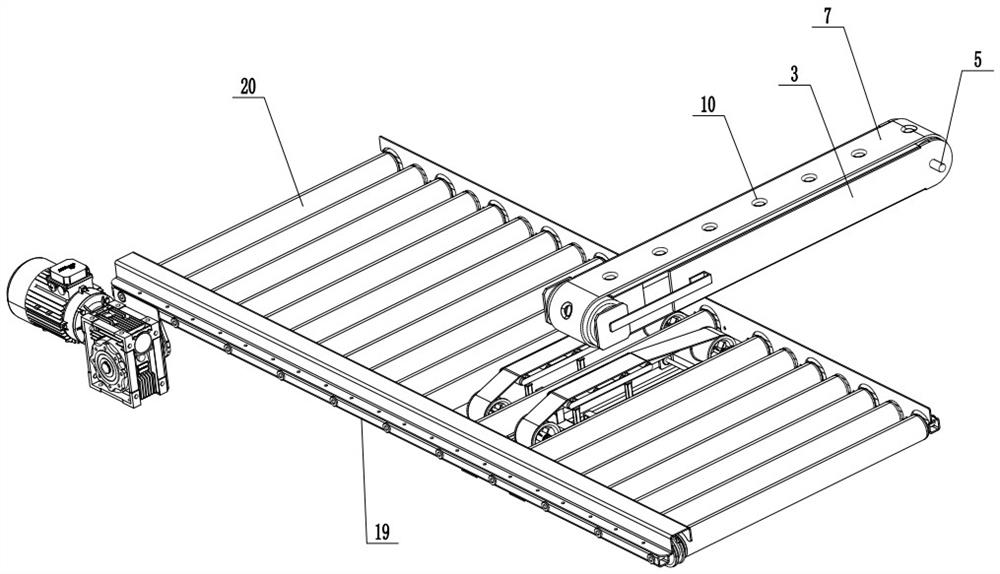

[0043] Embodiment: A kind of pasta automatic conveying and arranging machine

[0044] Such as Figure 1-14 Shown: This equipment is used for swinging the plate, including the belt conveyor module 1 and the roller conveyor module 2 which are set vertically in the conveying direction;

[0045] The incoming material end of described belt conveying module 1 is used for connecting with last procedure, picks up the pasta with filling that wraps and seals molding, and pasta is conveyed to roller conveying module 2;

[0046] The roller conveying module 2 is located below the material-discharging end of the belt conveying module 1, and is used to pick up the pasta falling from the belt conveying module 1 and transport the pasta to the next process.

[0047] The specific structure of the above modules is as follows:

[0048] The belt conveying module 1 includes a machine plate 3 oppositely arranged, and the incoming material end of the machine plate 3 (the end away from the roller conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com