Vertical film covering device based on V-method casting mold

A casting mold and film-covering device technology, applied in the field of mold casting, can solve problems such as damage, film pulling, and affecting work efficiency, and achieve reliable and uniform force, reliable adsorption and fixation, and improve casting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

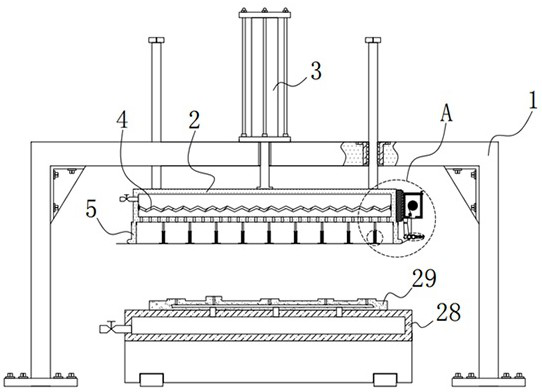

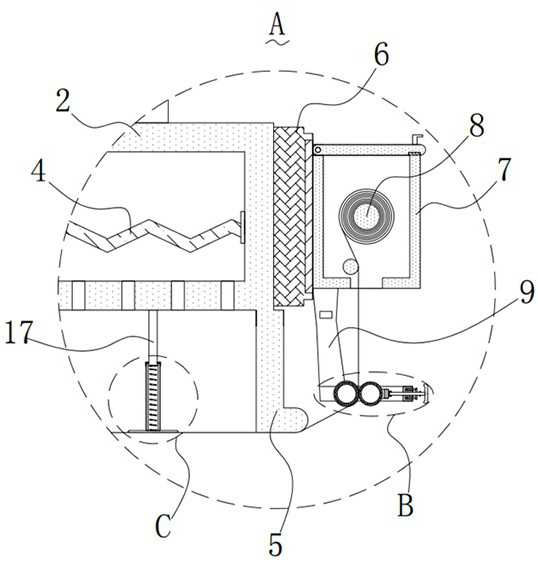

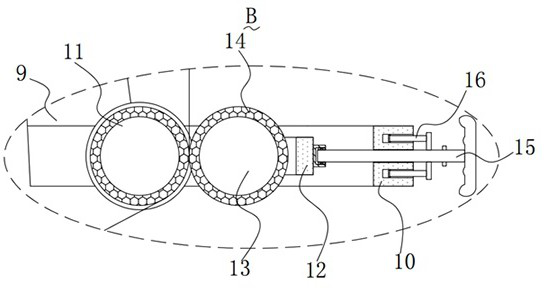

[0028] Please refer to Figure 1-Figure 7 , in this embodiment, the vertical coating device based on the V method casting mold includes a gantry 1, a heating box 2 is slidably installed on the top inner wall of the gantry 1, and a hydraulic cylinder 3 is fixedly installed on the top of the gantry 1 , the output shaft of the hydraulic cylinder 3 extends into the gantry 1 and is fixedly connected with the heating box 2, and the heating box 2 is fixedly installed with an electric heating wire 4, and the electric heating wire 4 is used to preheat the film to soften and heat the film. The bottom of the box 2 is integrally formed with a film-coated frame 5, the film-covered frame 5 is connected to the heating box 2, and a heat insulation board 6 is fixedly installed on one side of the heating box 2, and a mounting plate is embedded and fixed in the heat insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com