Array type assembly line garbage article intelligent fine sorting device

A sorting device and assembly line technology, applied in sorting and other directions, can solve the problems of expensive garbage sorting robot system, unfavorable large-scale popularization and application of small garbage collection stations, and long travel, so as to achieve simple and efficient motion planning and control , It is conducive to large-scale popularization and application, and the effect of small freedom of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

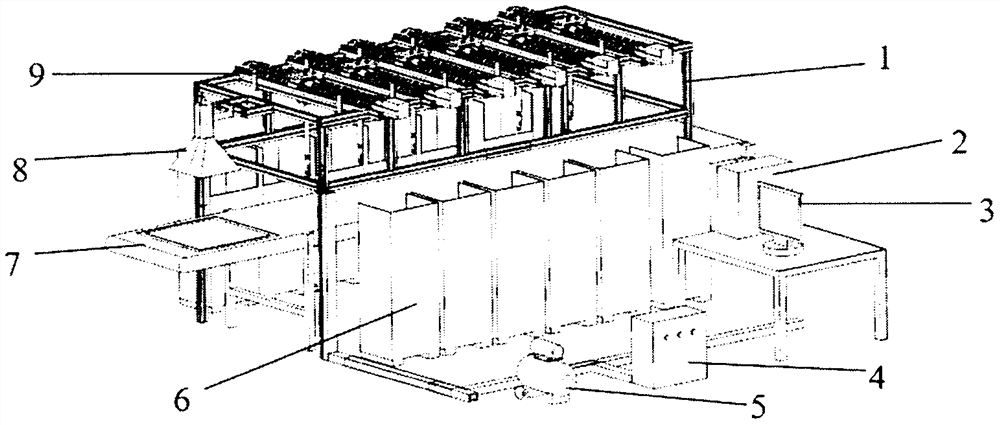

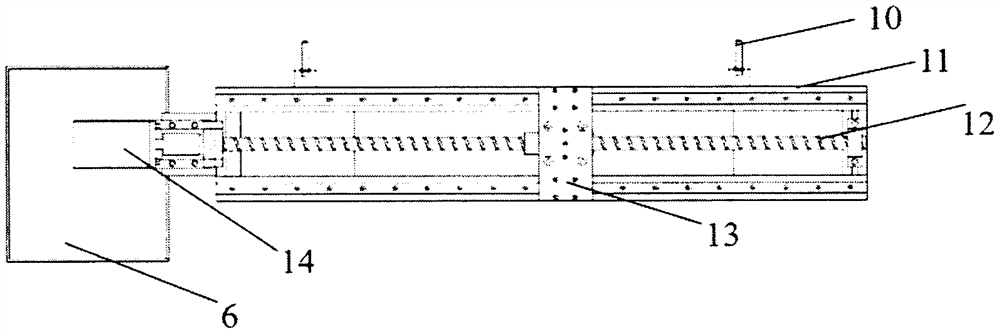

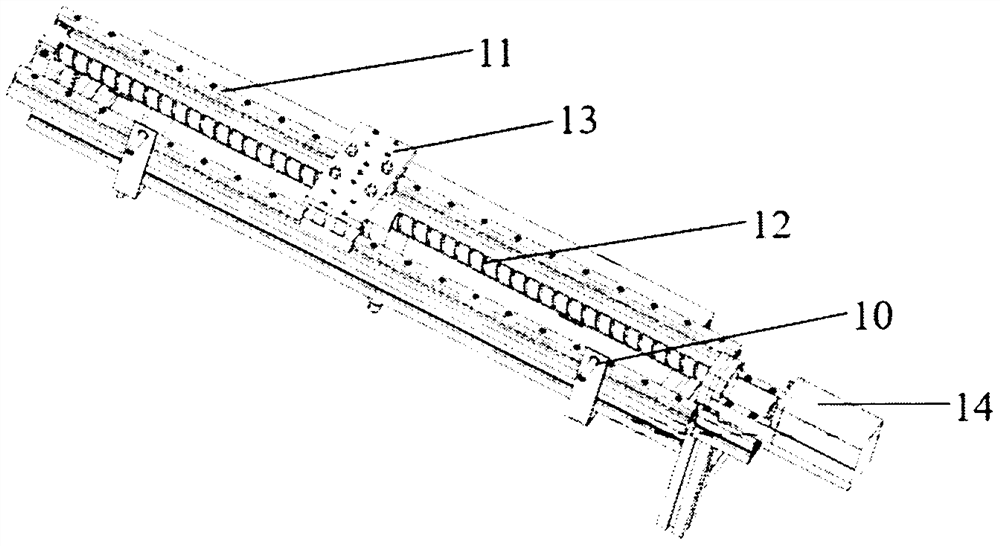

[0023] The patent of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the patent of the present invention, and are not used to limit the protection scope of the patent of the present invention.

[0024] The patented array-type assembly line intelligent fine sorting device for garbage items of the present invention can be widely deployed in small garbage collection stations or transfer stations to recycle useful materials, and can also be used in large-scale sorting system terminals to purify recycled materials.

[0025] The current garbage sorting platform mainly adopts the serial grabbing mode of industrial robotic arms. The technical bottlenecks of this mode are: low efficiency, high price and difficult control. The reasons are: serial grabbing plus a long single grabbing stroke, resulting in low sorting efficiency; industrial robotic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com