A kind of graphene modified ptc thermal conductive ink processing equipment

A technology of graphene modification and conductive ink, which is applied in the direction of sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as repeated repetitions, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The subject matter described herein will now be discussed with reference to example implementations. It should be understood that these embodiments are discussed only to enable those skilled in the art to better understand and implement the subject matter described herein, and not to limit the scope of protection, applicability, or examples set forth in the claims. Changes may be made in the function and arrangement of elements discussed without departing from the scope of the description. Various examples may omit, substitute, or add various procedures or components as desired. Additionally, features described with respect to some examples may also be combined in other examples.

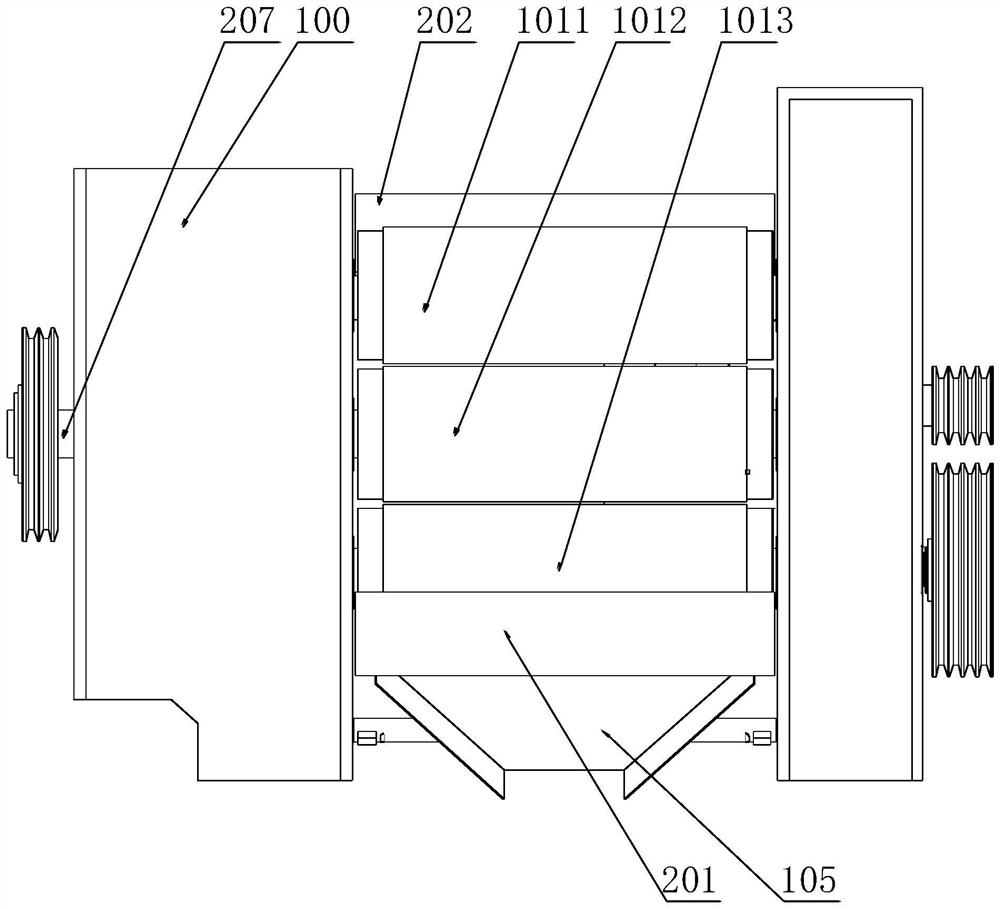

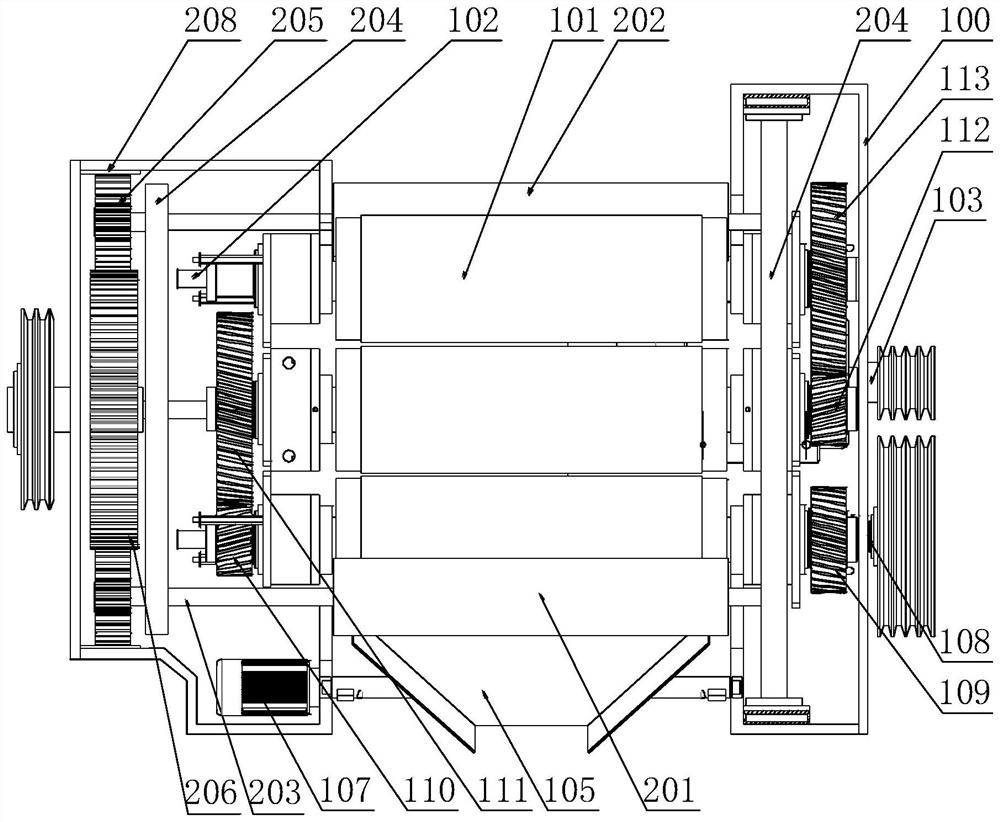

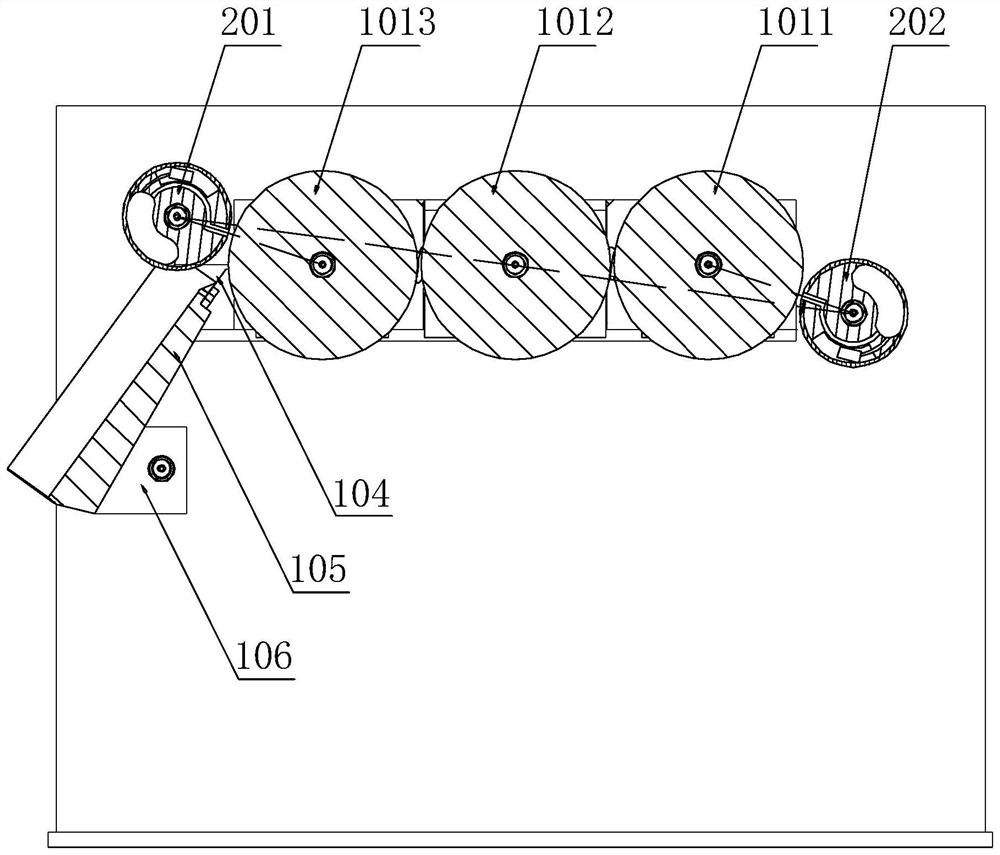

[0036] like Figure 1-Figure 6 As shown, a graphene-modified PTC heat-sensitive conductive ink processing equipment includes two chassis 100, three grinding rollers 101 are arranged between the two chassis 100, the center of the grinding rollers 101 is provided with a grinding shaft 102, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com