Lamp inspection method and device suitable for quantitative analysis of filling amount of smoke generation section of aerosol generation product

An aerosol generation and quantitative analysis technology, which is applied in measuring devices, volume measuring instruments/methods, and material analysis through optical means, can solve problems such as inaccurate test results, high labor intensity for testers, and small product diameters. Achieve the effects of improving detection efficiency, facilitating product inspection, and reducing fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment illustrates a method of light inspection for the filling amount of the smoke section of the aerosol generating product, and a light inspection method for quantitative analysis, including the following steps:

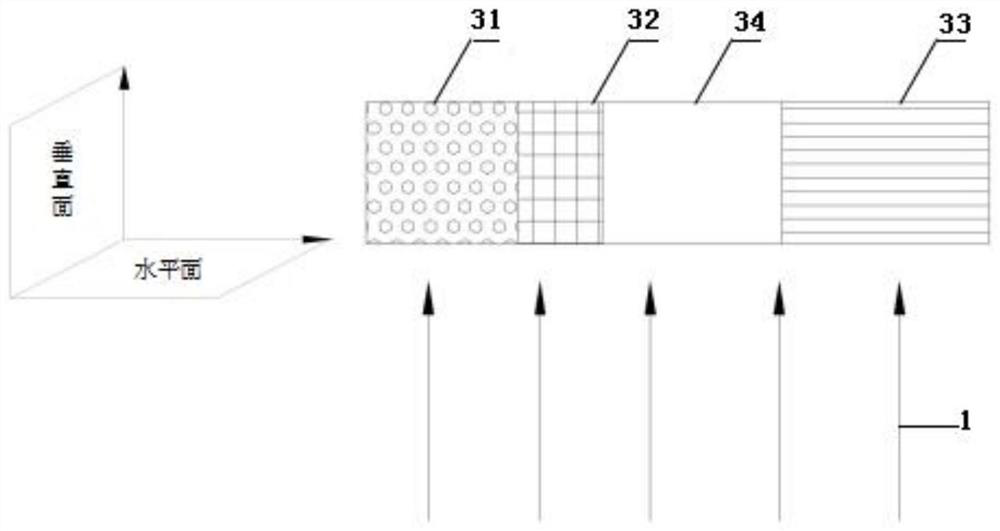

[0052] (1) Fill the aerosol generating product to be detected into the sample holding tank 23, then place the light inspection box 2 in front of the surface light source 1, and place the axis of the aerosol generating product and the horizontal plane between the line and the plane. The angle is 90°, and the axis of the aerosol generating product is perpendicular to the horizontal light beam provided by the surface light source 1; as figure 2 and Figure 4 shown.

[0053] (2) Turn on the surface light source 1 so that the light beam emitted by the surface light source 1 can pass through the aerosol generating product contained in the light inspection box 2, according to the shadow of the opaque area in the smoke section of the aerosol generating p...

Embodiment 2

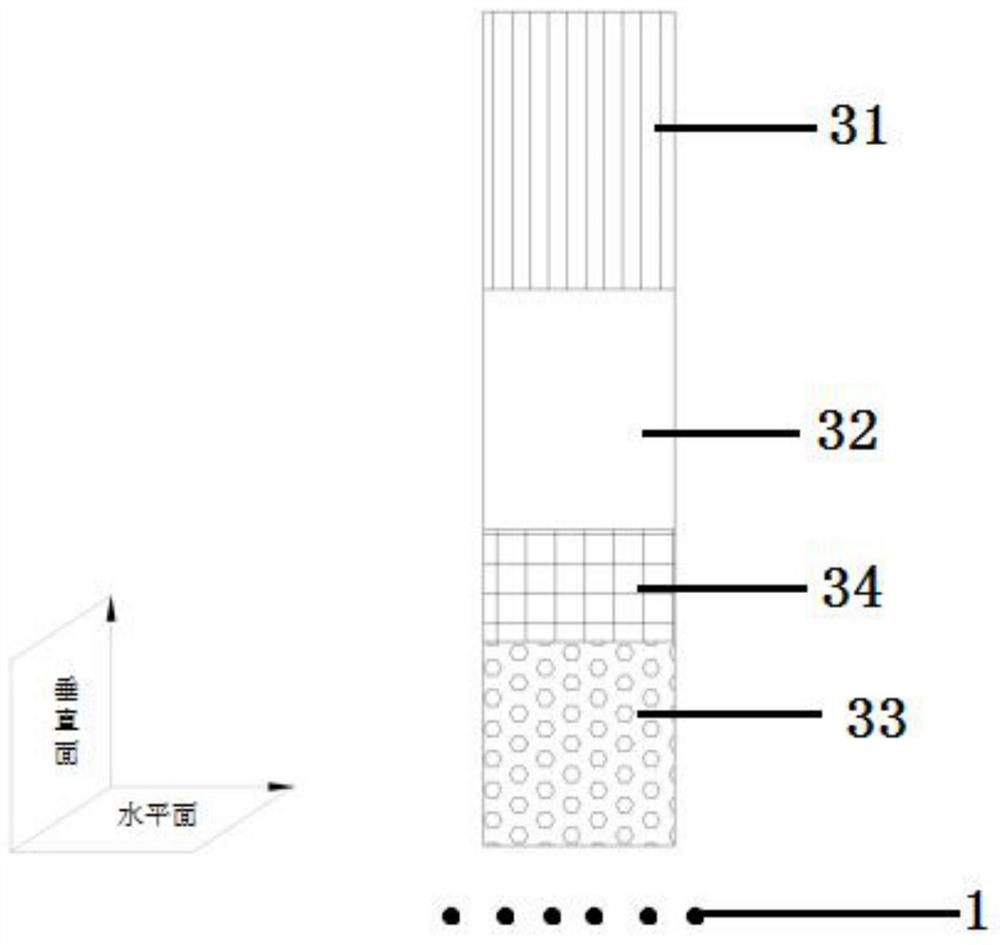

[0059] The light inspection method used in this embodiment is consistent with that in Embodiment 1, the difference is that the angle between the axis of the aerosol generating product 3 contained in the light inspection box 2 and the horizontal plane is 0°, and the light emitted by the surface light source 1 The horizontal light beam passes through the aerosol generating product 3, and the axis of the aerosol generating product is perpendicular to the horizontal light beam provided by the surface light source 1; as image 3 shown. That is, on the basis of embodiment 1, the lamp inspection box 2 is directly rotated 90 °, see Figure 5 shown.

[0060] More intuitively, with Figure 4 same, Figure 5 The horizontal light beam generated by the mid-surface light source 1 is from the inside of the paper to the outside of the paper, and the inspector observes the aerosol generating product in the light inspection box 2 from outside the paper perpendicular to the paper.

[0061] T...

Embodiment 3

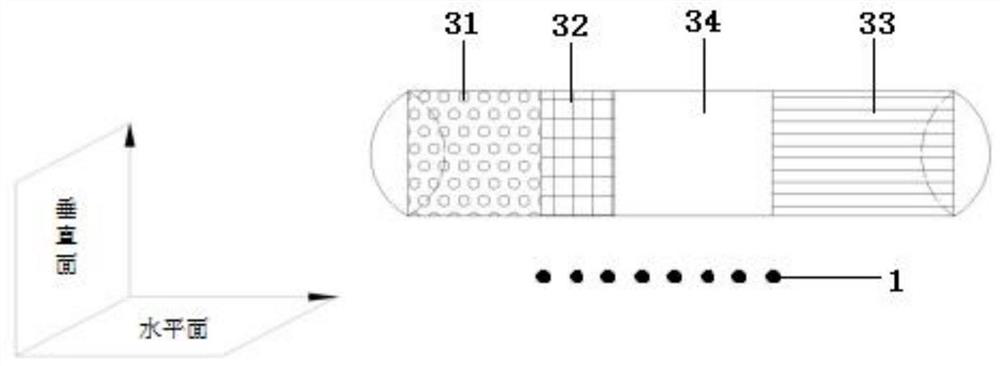

[0063] The light inspection method used in this embodiment is consistent with that in Embodiment 1, the difference is that the axis of the aerosol generating product 3 accommodated in the light inspection box 2 and the line-plane angle of the horizontal plane are 60°, and the light emitted by the surface light source 1 The horizontal light beam passes through the aerosol generating product 3 , and the axis of the aerosol generating product is perpendicular to the horizontal light beam provided by the surface light source 1 . That is, on the basis of embodiment 1, the lamp inspection box 2 is directly rotated 30 °, see Figure 6 shown.

[0064] More intuitively, with Figure 4 same, Figure 6 The horizontal light beam generated by the mid-surface light source 1 is from the inside of the paper to the outside of the paper, and the inspector observes the aerosol generating product in the light inspection box 2 from outside the paper perpendicular to the paper.

[0065] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com