Drying and storing integrated device for screen printing plate

A screen printing plate and drying technology, applied in the directions of drying gas layout, drying solid materials, printing plate preparation, etc., can solve the problems of large space occupation and many processes, and achieve the solution of large space occupation, reasonable layout, avoiding pollution or other problems. the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

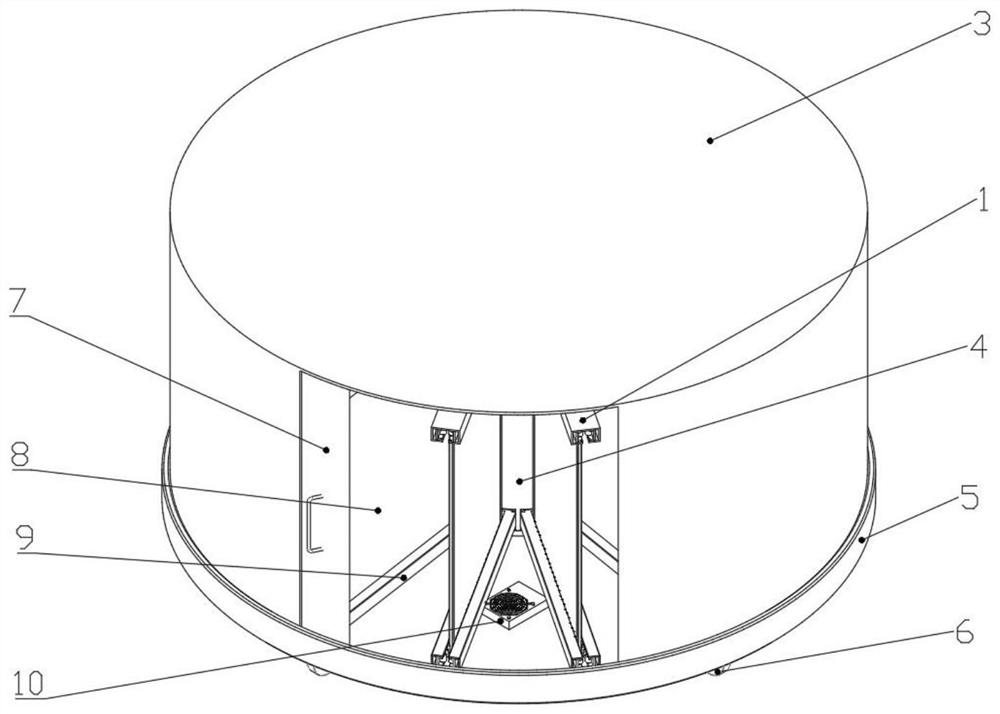

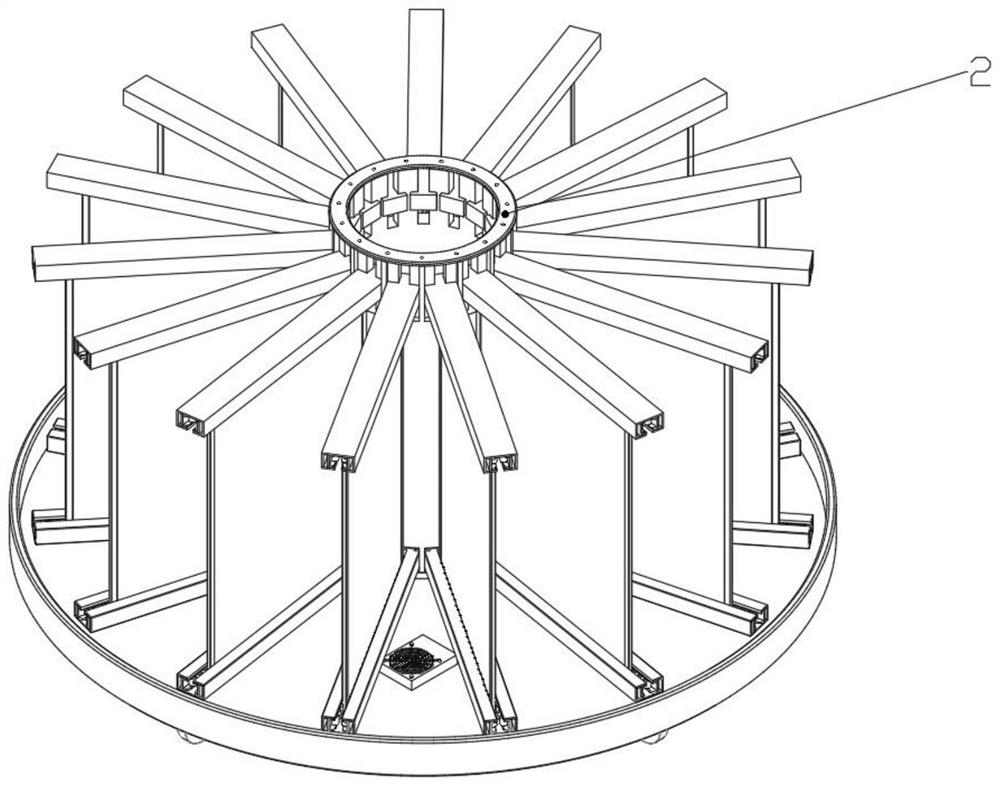

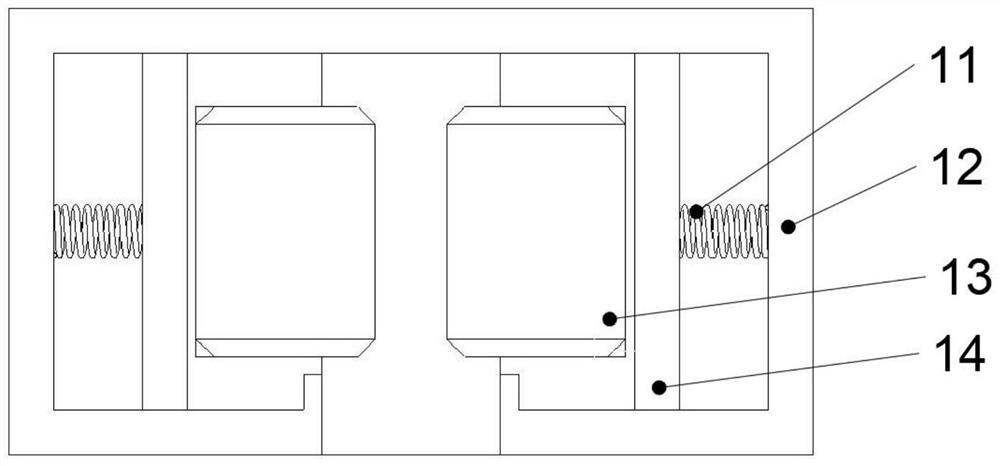

[0027] Embodiment 1: as Figure 1-14 As shown, a screen printing plate drying and storage integrated device includes an upper clamping body 1, a top cover 2, a protective cover 3, a base column 4, a base 5, a lower clamping body 9, and a blowing device 10; wherein, The base 5 is matched with the base column 4 installed thereon through the hole shaft and the base column 4 can rotate around the axis (such as: the bottom of the base column 4 has a round hole, which is matched with the shaft clearance on the base 5 / through a sliding bearing, etc. Connect so that the base column 4 is installed on the base 5 and can rotate around the circular axis on the base 5, that is, the base column 4 can rotate 360 degrees around the circular axis on the base 5 to facilitate access to the screen printing plate 8), on The clamping body 1 and the lower clamping body 9 form a storage frame for the screen printing plate 8, and the upper clamping body 1 and the lower clamping body 9 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com