Graded coordination strengthening method for broken surrounding rocks in coal roadway driving

A technology for breaking surrounding rock and coal roadway, which is applied in the field of grading coordination and strengthening of broken surrounding rock in coal roadway excavation, can solve the problems of safety and stability of difficult roadway, high maintenance cost, poor coal pillar stability, etc., and achieves improvement of the strength and integrity of surrounding rock. , The effect of improving the strength and stability of the coal pillar, and improving the strength and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be briefly described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other implementations obtained by those skilled in the art without creative work Examples, all belong to the protection scope of the present invention.

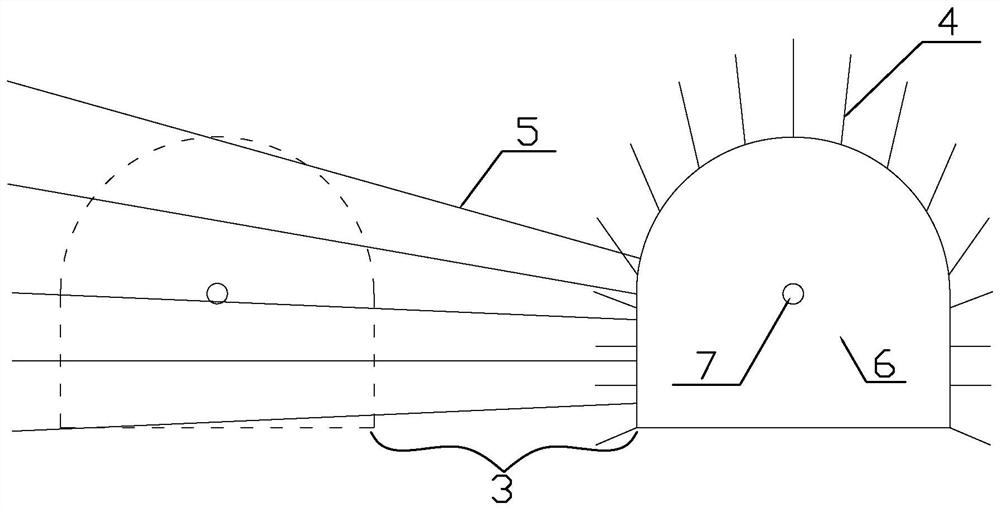

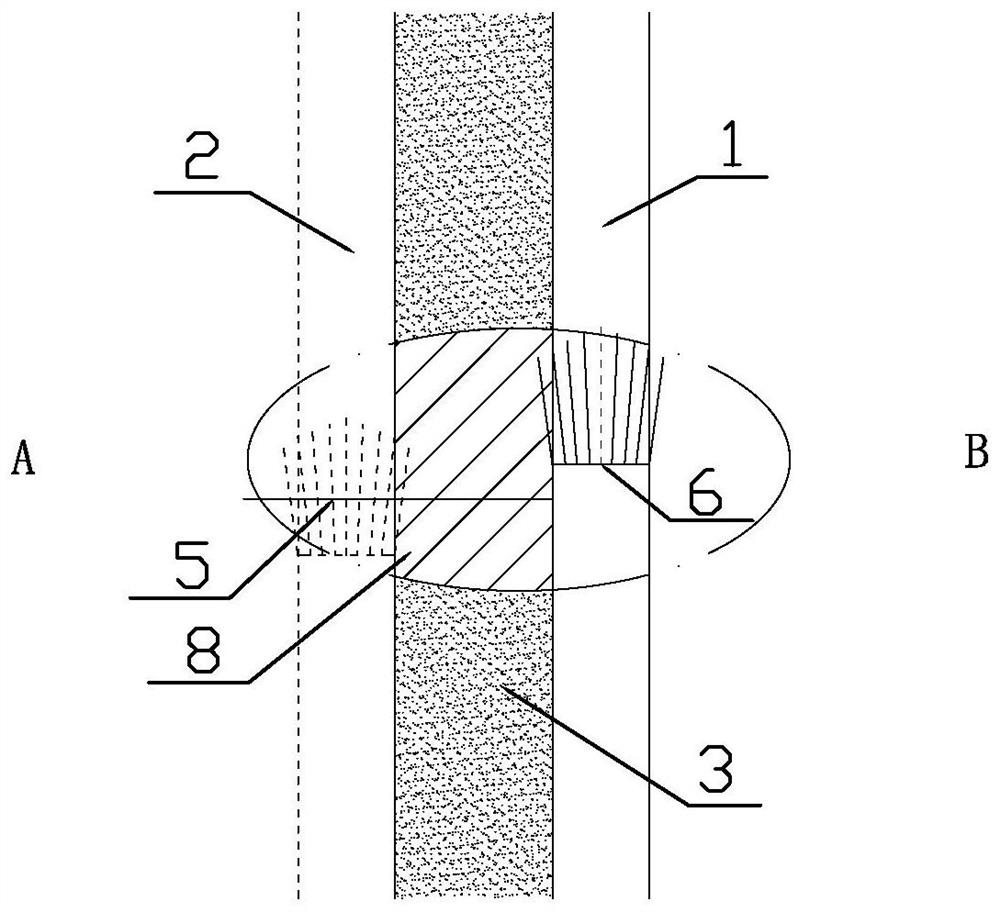

[0025] Figure 1-Figure 2 A preferred embodiment of the present invention is shown and analyzed in detail.

[0026] A roadway is a semi-mudstone roadway, the roof lithology is argillaceous siltstone, the upper layer of the side is coal, the lower layer is mudstone, the floor lithology is fine sandstone, the roof and two sides are seriously broken and deformed, and the bolt (cable) is seriously unanchored . In order to control the deformation and instability of the surrounding rock of the roadway, it is urgent to strengthen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com