Integrated platform for construction in C-shaped steel core tube

A technology of C-shaped steel and core tubes, which is applied in the field of integrated platforms constructed in C-shaped steel core tubes, can solve problems such as non-returnable use, potential safety hazards, and difficult disassembly, and achieve more turnover times, high safety, and convenient disassembly and transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated below by specific examples.

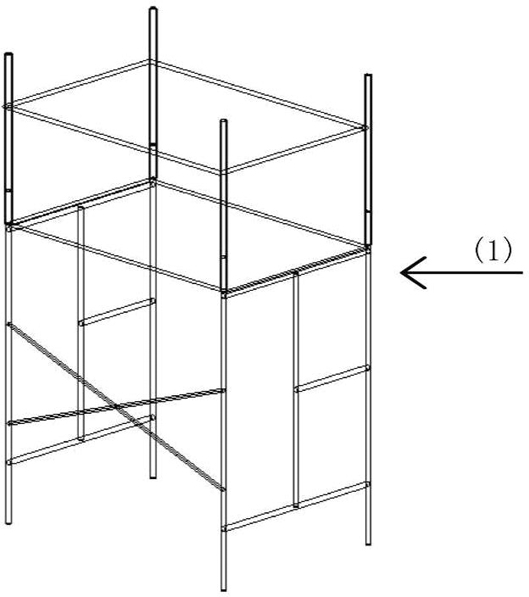

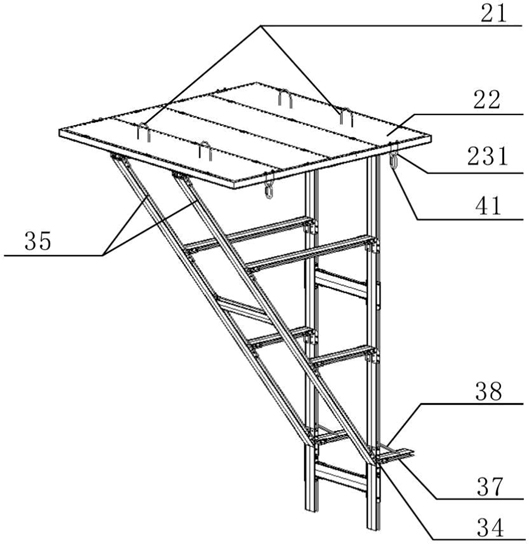

[0031] Such as Figure 3~Figure 11 As shown, an integrated platform for construction in a C-shaped steel core tube, including a scaffold operating frame body (1), an upper steel platform (2), a triangle support frame (3), a connecting device (4), a movable tight Fixing device (5) and lower steel frame protective body (6); two rows of triangular bracing frames (3) and upper steel platform (2) are connected to form the operation platform working surface to fix the scaffolding operating frame body (1), triangular bracing frame (3) It is connected with the lower steel frame protection body (6) through the connection device (4) to form a whole, and the fixing part at the lower part of the lower steel frame protection body (6) is stuck in the movable fastening device (5) in the well wall Provides protection for the interior of the core shaft shaft.

[0032] In the integrated platform for construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com