Intelligent fuse box of new energy automobile

A technology for new energy vehicles and fuse boxes, applied in the field of smart fuse boxes, can solve the problems of time-consuming and labor-intensive, long wire loops, and heavy workload, and achieve the effects of reducing cost and weight, reducing the use of wiring harnesses, and reducing wiring harness connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

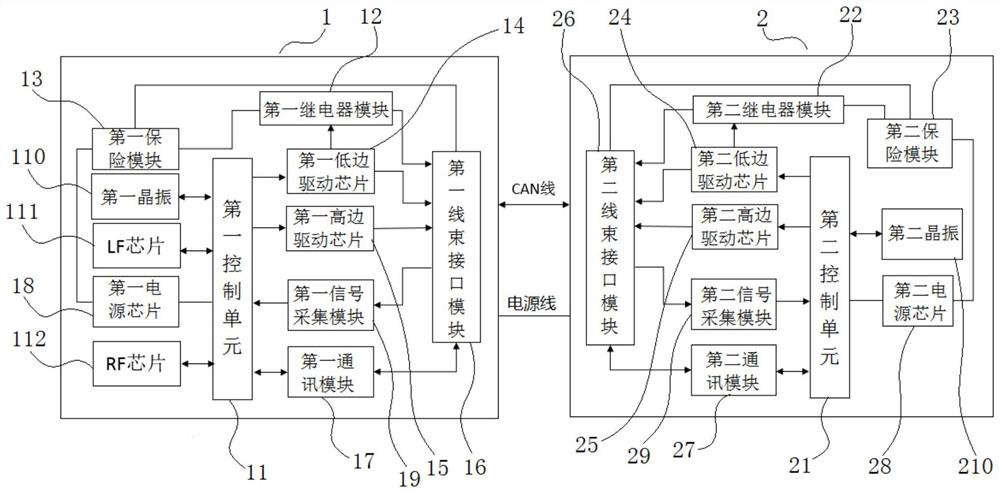

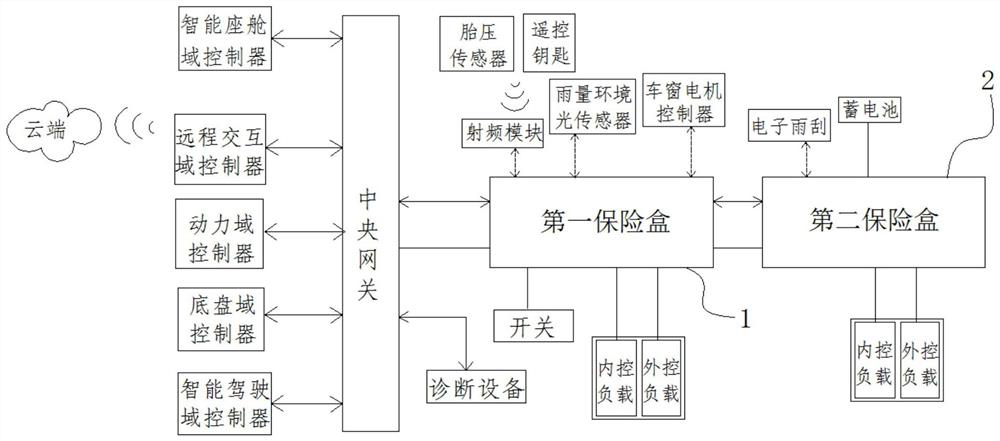

[0020] Such as figure 1 , figure 2 As shown, the smart fuse box of the new energy vehicle in this embodiment includes a first fuse box 1 arranged in the cab and a second fuse box 2 arranged in the engine compartment.

[0021] The first fuse box 1 includes a first control unit 11, a first wire harness interface module 16, a first insurance module 13 connected to the first wire harness interface module 16, and a first wire harness interface module 16 connected to the first insurance module 13. A relay module 12, a first low-side driver chip 14 connected to the first wire harness interface module 16, the first control unit 11, and the first relay module 12, a first low-side driver chip 14 connected to the first wire harness interface module 16, and the first control unit 11 A high-side driver chip 15, a first communication module 17 connected to the first wire harness interface module 16 and the first control unit 11, a first power supply chip 18 connected to the first insuranc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com