Off-board pre-adjusting and correcting device

A calibration device and pre-adjustment technology, applied to positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as clamping errors, inconvenient parts and fixture clamping error detection, and affecting machine operation. To achieve the effect of improving the machine's utilization and facilitating normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

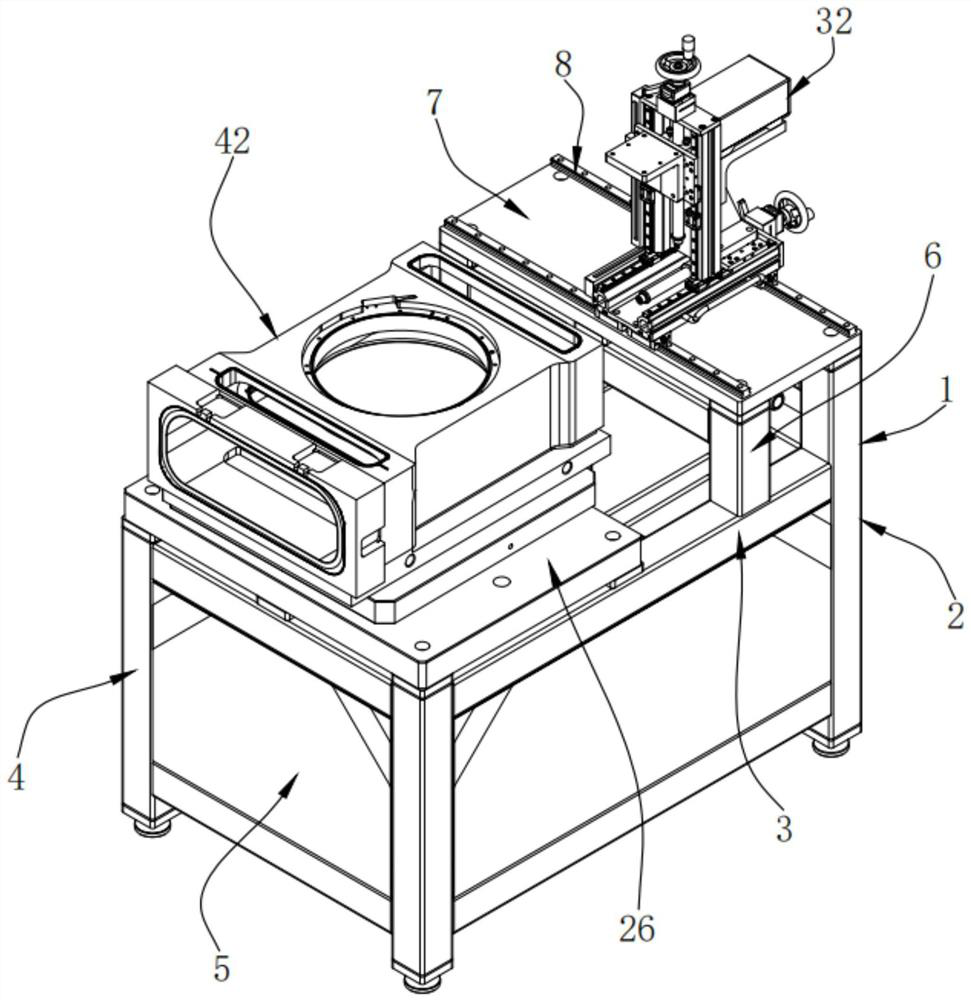

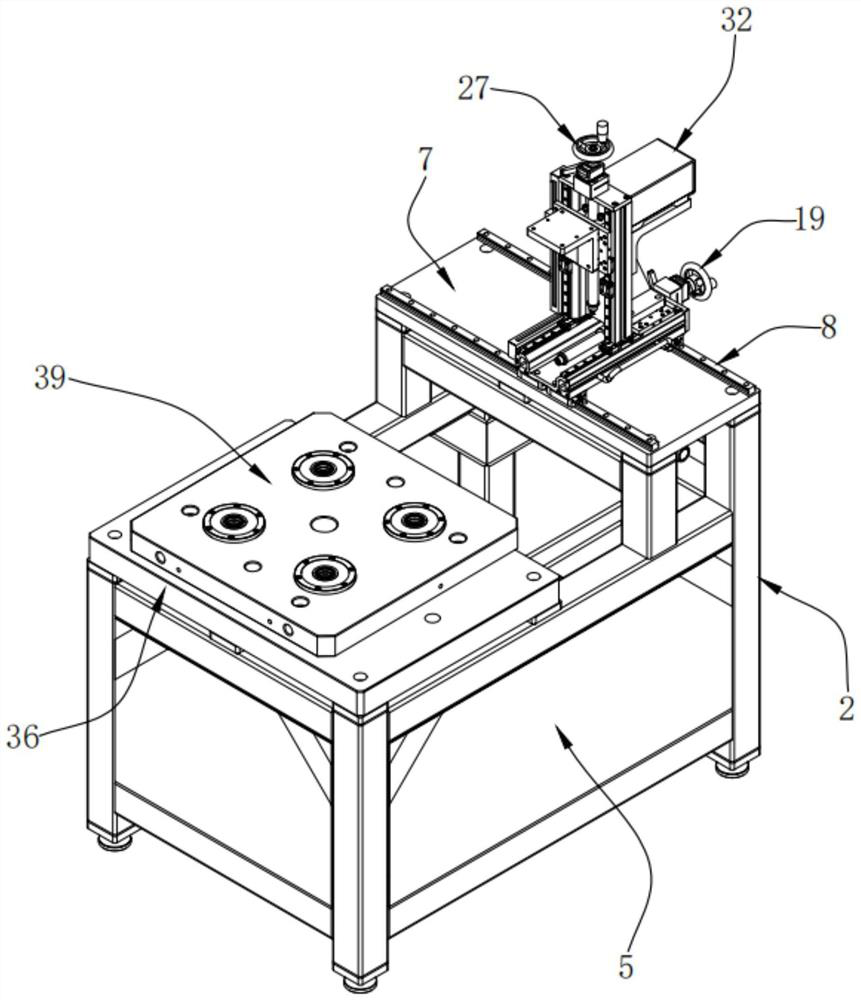

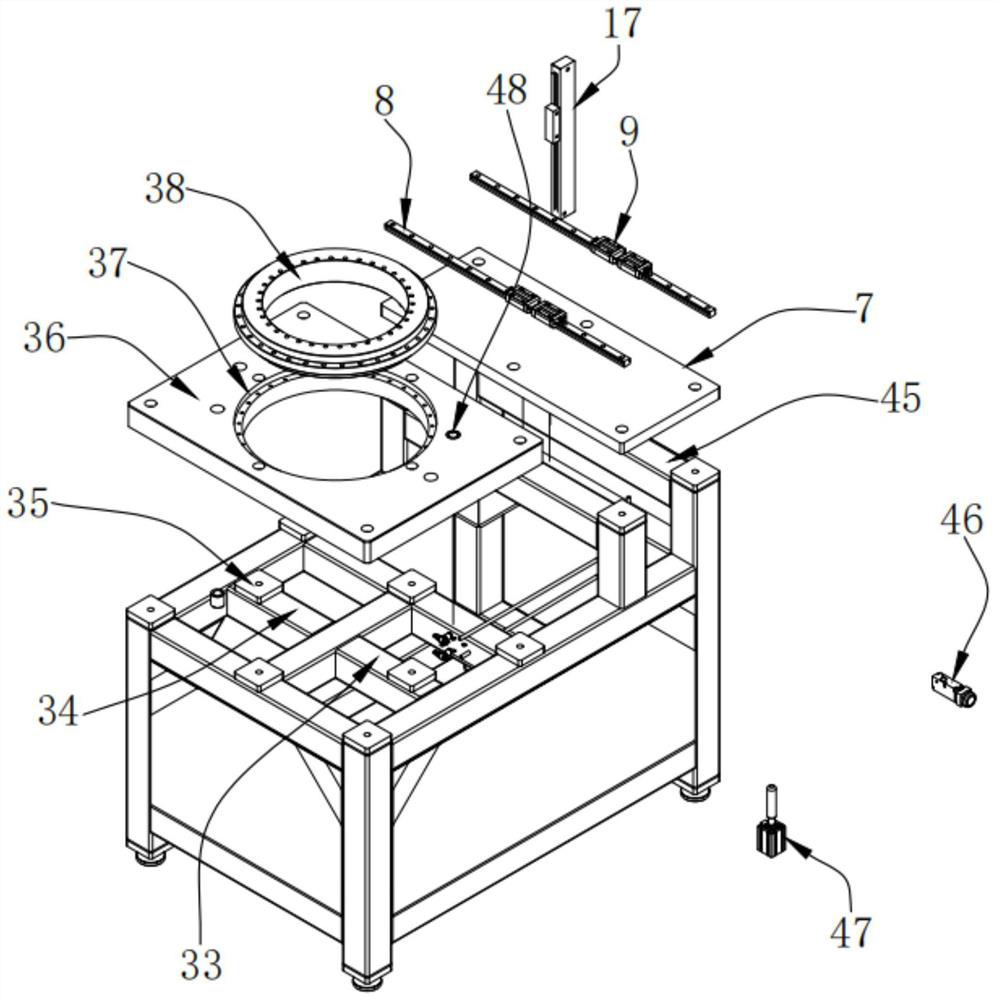

[0028] see Figure 1-8 , the present invention provides a technical solution: an external preset correction device, including a correction adjustment mechanism 1 and a rotation adjustment mechanism 34, the correction adjustment mechanism 1 includes a first vertical bar 2, a first horizontal bar 3, a first slide Rail 8, first slide block 9, first U-shaped seat 10, second U-shaped seat 22 and V-shaped frame 23;

[0029] The front sides of the two first vertical bars 2 are fixedly connected with the first horizontal bar 3, and the bottom of the first horizontal bar 3 is fixedly connected with the second vertical bar 4, and the second vertical bar 4 and the first vertical bar 2 are fixed. A first support plate 5 is connected, a vertical block 6 is fixedly connected to the top of the first horizontal bar 3, a horizontal plate 7 is fixedly connected between the top of the vertical block 6 and the top end of the first vertical bar 2, and the top of the horizontal plate 7 is fixed Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com