Machining method for thin-wall special-shaped pipe part

A processing method and special-shaped tube technology, which is applied in the field of aerospace machining, can solve the problems of difficulty in guaranteeing processing quality, unstable processing pass rate, and affecting the progress of scientific research and production, so as to reduce cutting stress and ensure high shape accuracy. The effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

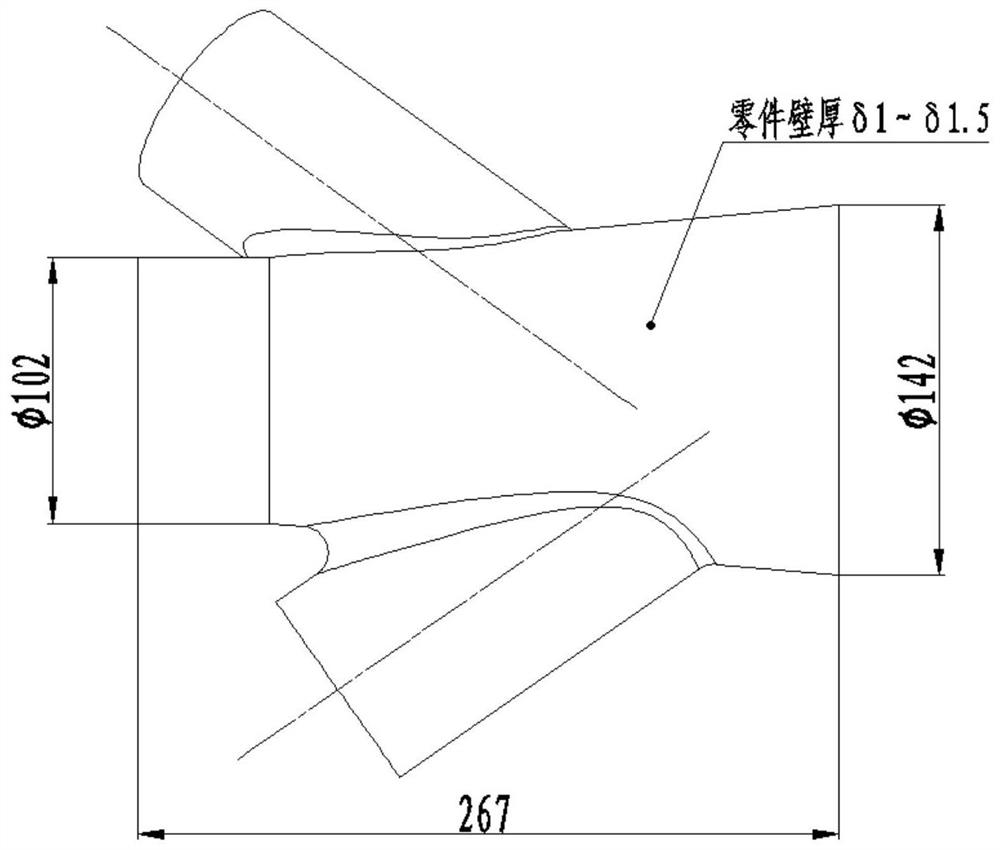

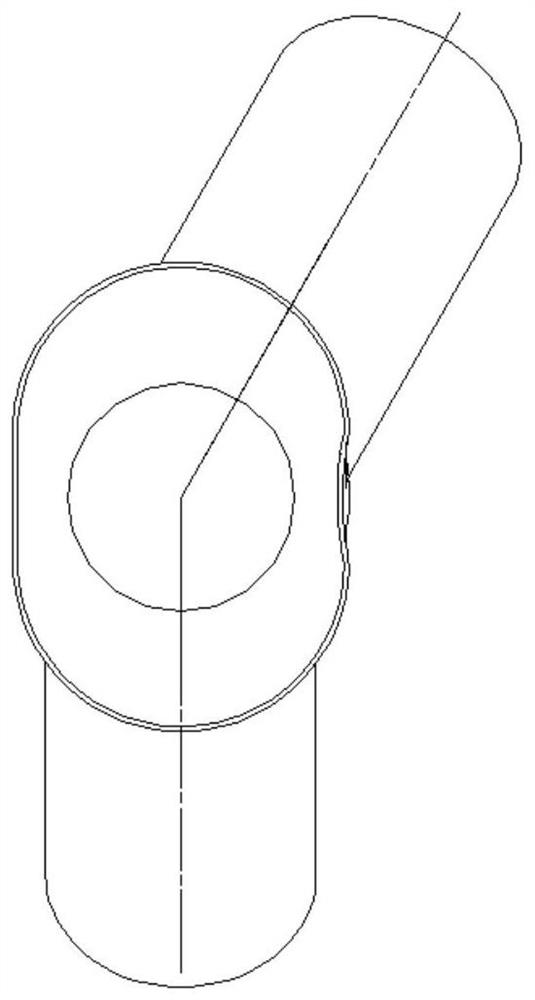

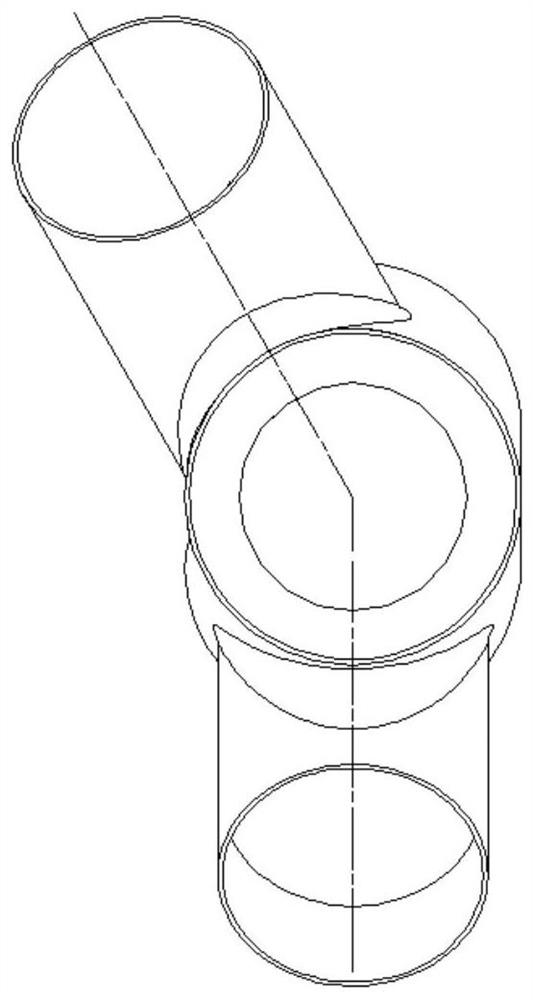

[0043] against Figure 1 ~ Figure 3 The problems of shape accuracy and position accuracy that are easy to occur in the processing of the shown parts, low production qualification (less than 40%), the invention provides a processing method:

[0044] Such as Figure 1 to Figure 5 As shown, it is a part diagram of thin-walled special-shaped pipe body and a schematic diagram of the state after clamping, where:

[0045] The thin-wall sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com