Automatic production equipment for food-grade polyurethane grain lifting belt and use method of automatic production equipment

An automatic production and lifting belt technology, which is applied to conveyors, devices for coating liquid on the surface, transportation and packaging, etc., can solve the problems of inability to adjust the tension of the lifting belt, uneven coating, and low processing efficiency, so as to prevent Effects of coagulation, reduction of accumulation, and improvement of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

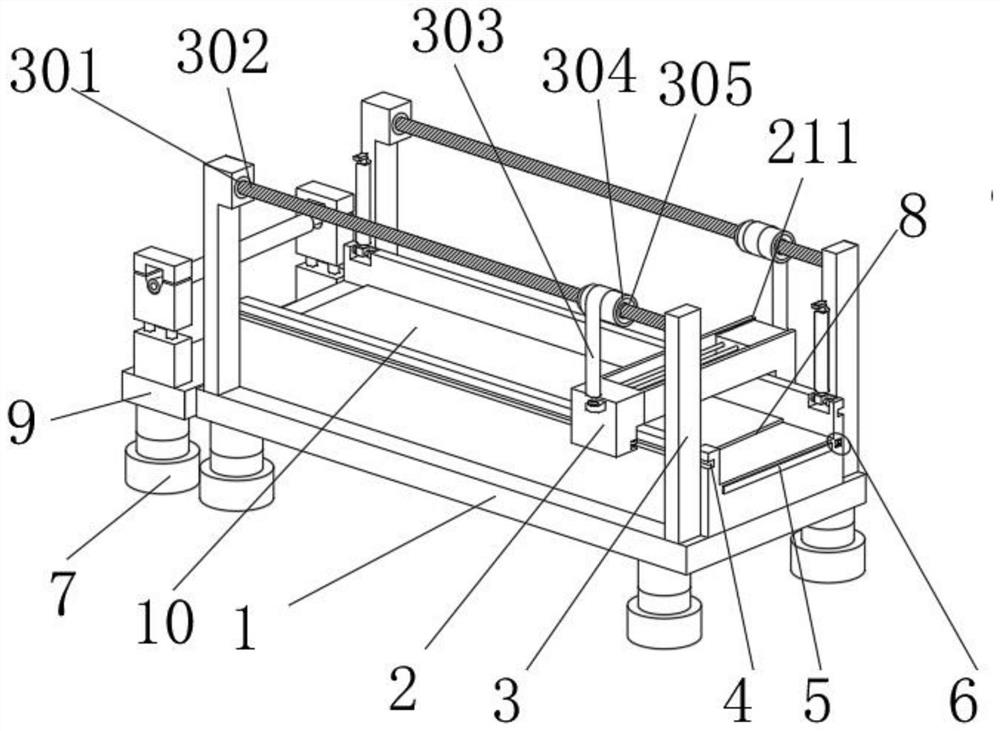

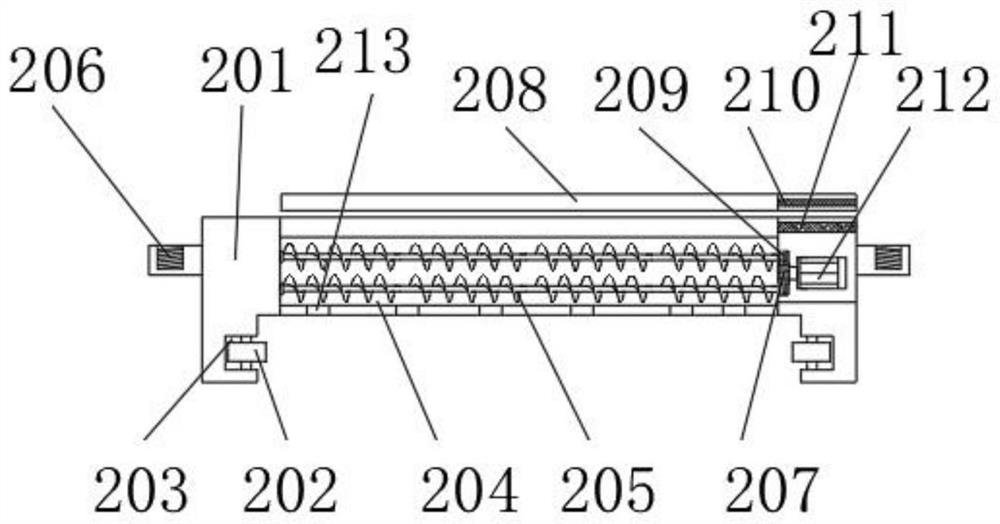

[0035] Such as Figure 1-Figure 4 Shown, a kind of food-grade polyurethane grain lifting belt automatic production equipment of the present invention comprises the tension adjustment mechanism 9 that is installed on the left side of main body 1 and is used for adjusting the tension of polyurethane grain lifting belt. A heating plate 5 is installed inside, a limiting groove 4 is set on both sides above the main body 1, a feeding mechanism 2 is installed inside the limiting groove 4, a coating mechanism 3 is installed on the upper side of the main body 1, the lower part of the main body 1 and the tension adjusting mechanism 9 are both Multiple hydraulic support seats 7 are installed,

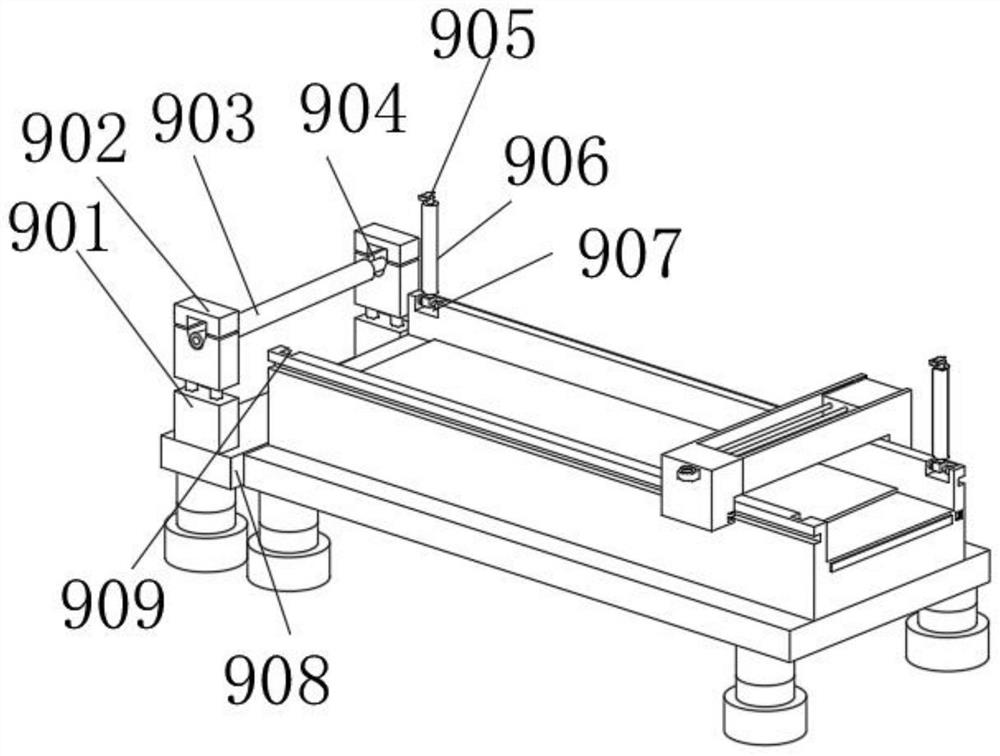

[0036] The tension adjustment mechanism 9 includes a mounting seat 908, a hydraulic strut 901, a material roller 903 and a pressure roller 906, and both sides above the mounting seat 908 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com