Bidirectional impact crushing equipment for coal mining coal materials

A technology for impact crushing and coal material, applied in the field of machinery and equipment, can solve the problems of high working intensity, high extrusion strength, poor crushing effect, etc., and achieve the effects of improving practicability and reliability, avoiding injury, and facilitating protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

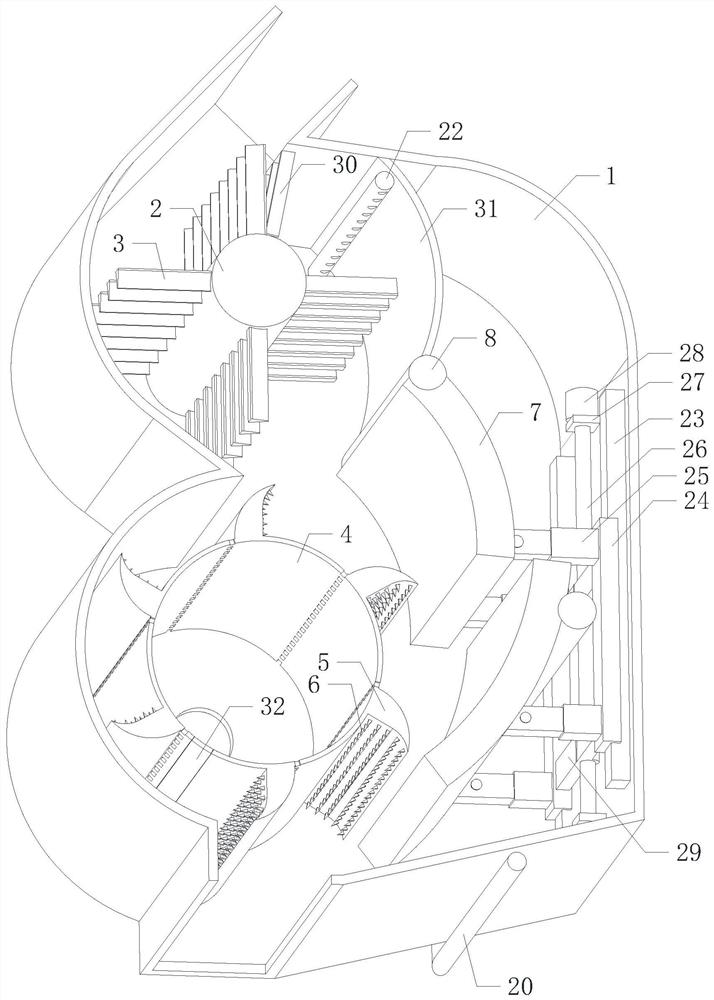

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

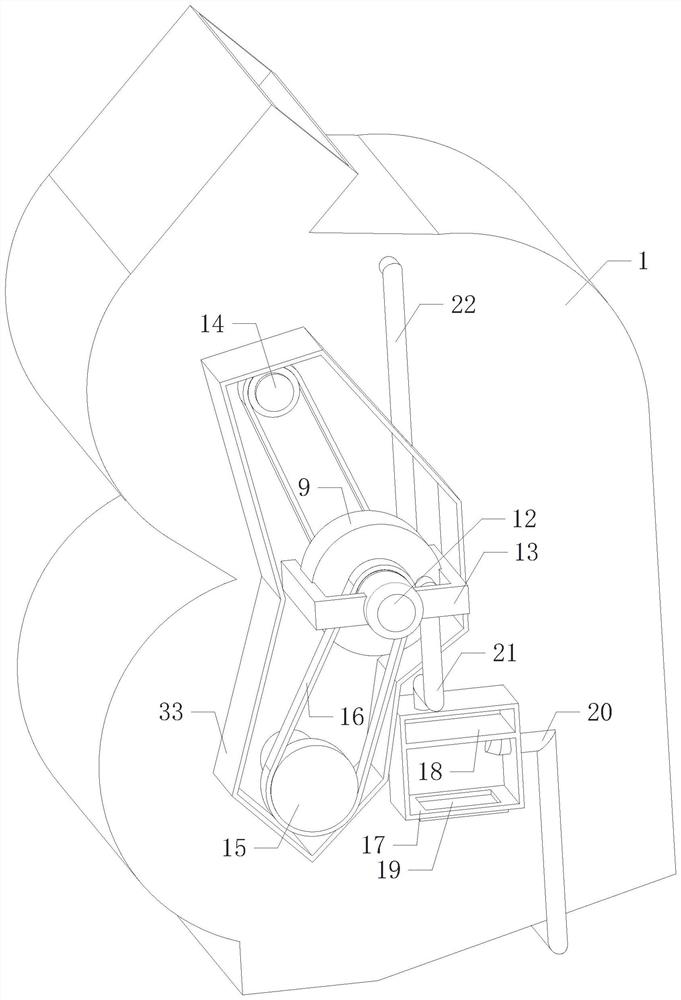

[0020] like Figure 1 to Figure 5 As shown, a kind of two-way impact crushing equipment for coal mining in coal mining of the present invention, when it is working, opens the power mechanism, and the power mechanism drives the first rotating shaft 2 and the rotating cylinder 4 to rotate, and the first rotating shaft 2 and the rotating cylinder 4 The direction of rotation is opposite, the first rotating shaft 2 and the rotating cylinder 4 respectively drive multiple sets of riving knives 3, multiple sets of arc-shaped impact plates 5 and multiple sets of crushing cones 6 to rotate, and the adjustment mechanism can adjust two sets of arc-shaped impact plates 7 times The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com