Grinding equipment for chili powder

A technology for chili powder and equipment, applied in the field of chili powder grinding equipment, can solve the problems of inconvenient collection, poor sealing and the like, and achieve the effects of easy collection, easy handling, and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A grinding equipment for paprika such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first mounting block 2, a first connecting block 3, a second connecting block 4, a millstone 5, a rotating mechanism 6 and a charging mechanism 7, and the top of the base 1 is symmetrically provided with a first mounting block 2, The top of the first mounting block 2 is provided with a charging mechanism 7, the charging mechanism 7 is provided with a first connecting block 3, and a second connecting block 4 is arranged between the top of the first mounting block 2, and the second connecting block 4 is internally rotatable A grinding disc 5 is provided, and the grinding disc 5 rotates in the first connecting block 3 , and a rotating mechanism 6 is provided on the first mounting block 2 .

[0033] The rotating mechanism 6 includes a second mounting block 60, a servo motor 61 and a rotating shaft 62. The top of the first mounting block 2 is provided with a second ...

Embodiment 2

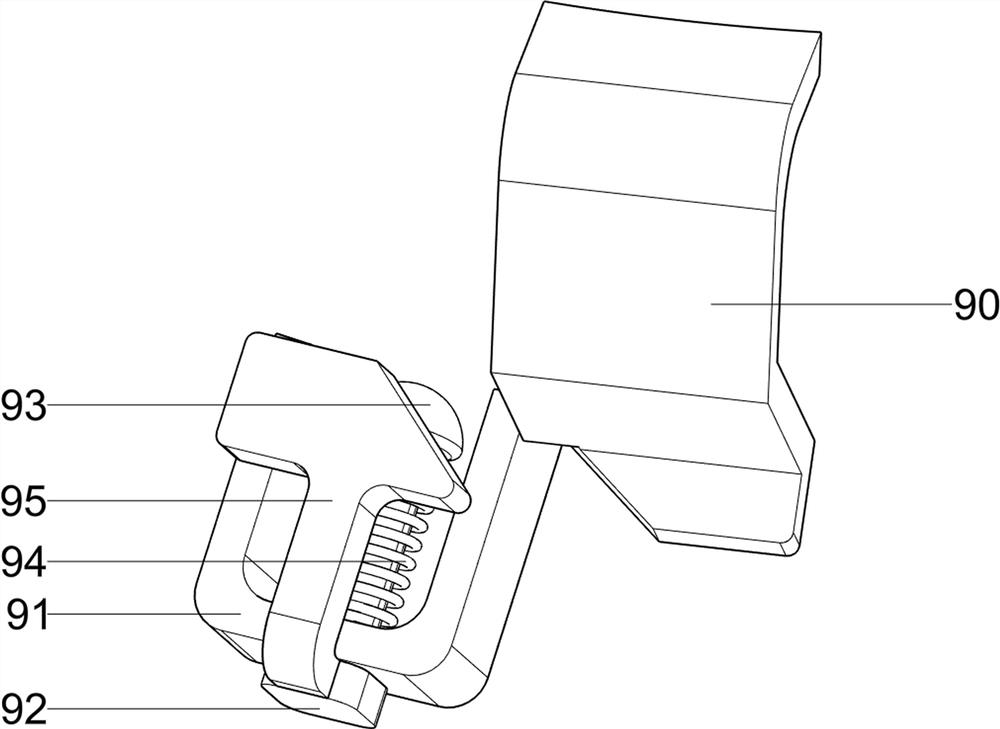

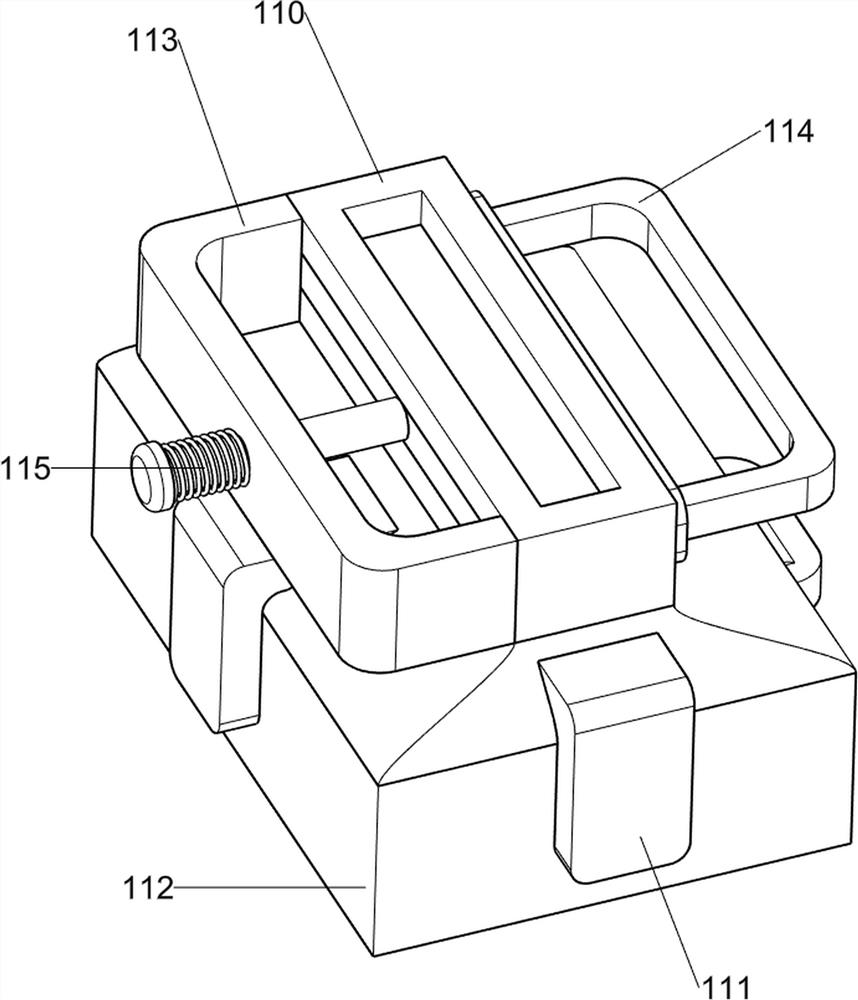

[0037] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11As shown, it also includes a blanking mechanism 8, and the blanking mechanism 8 includes a baffle plate 80, a fourth mounting block 81, a second charging box 82, a toggle block 83, a fifth mounting block 84, a first slide block 85, The first spring 86 and the fourth connecting block 87, the right side of the second connecting block 4 is provided with a baffle plate 80, the rear side of the top of the base 1 is provided with a fourth mounting block 81, and the fourth mounting block 81 is connected with the second connecting block 4 connection, a second charging box 82 is provided on the top of the fourth mounting block 81, a toggle block 83 is provided on the top of the rotating shaft 62, a fifth mounting block 84 is provided on the right side of the bottom of the second charging box 82, and the fifth mounting block 84 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com