Secondary salinization soil leacheate sampling device

A secondary salinization and soil leaching technology, applied in the field of soil remediation, can solve the problem of sampling without a sampling device, and achieve the effect of simple and convenient operation and convenient detection and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

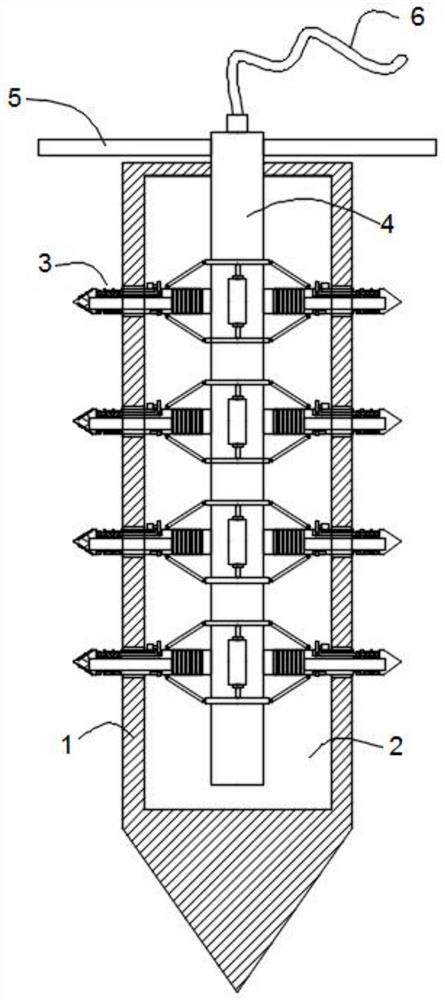

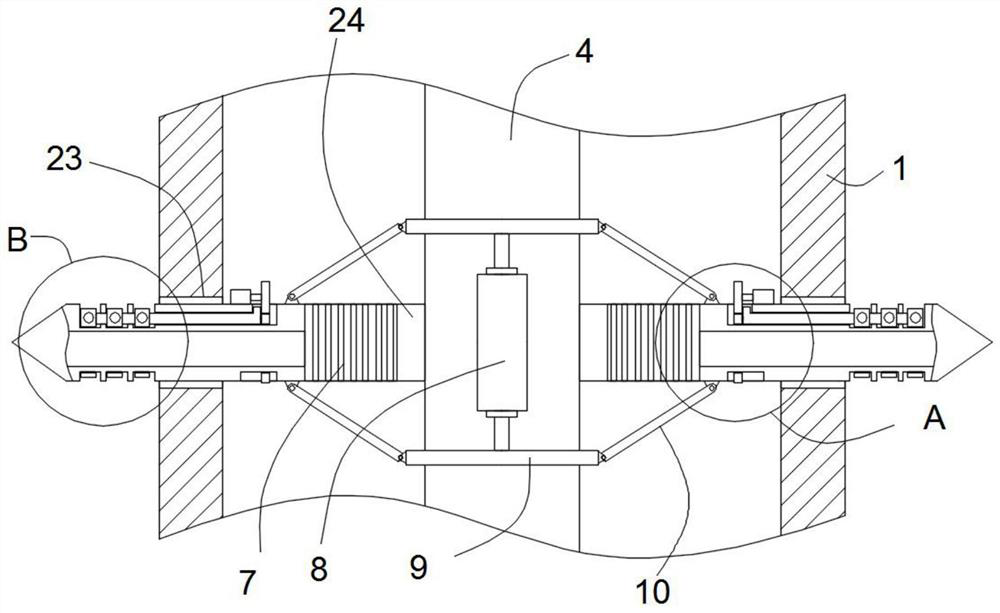

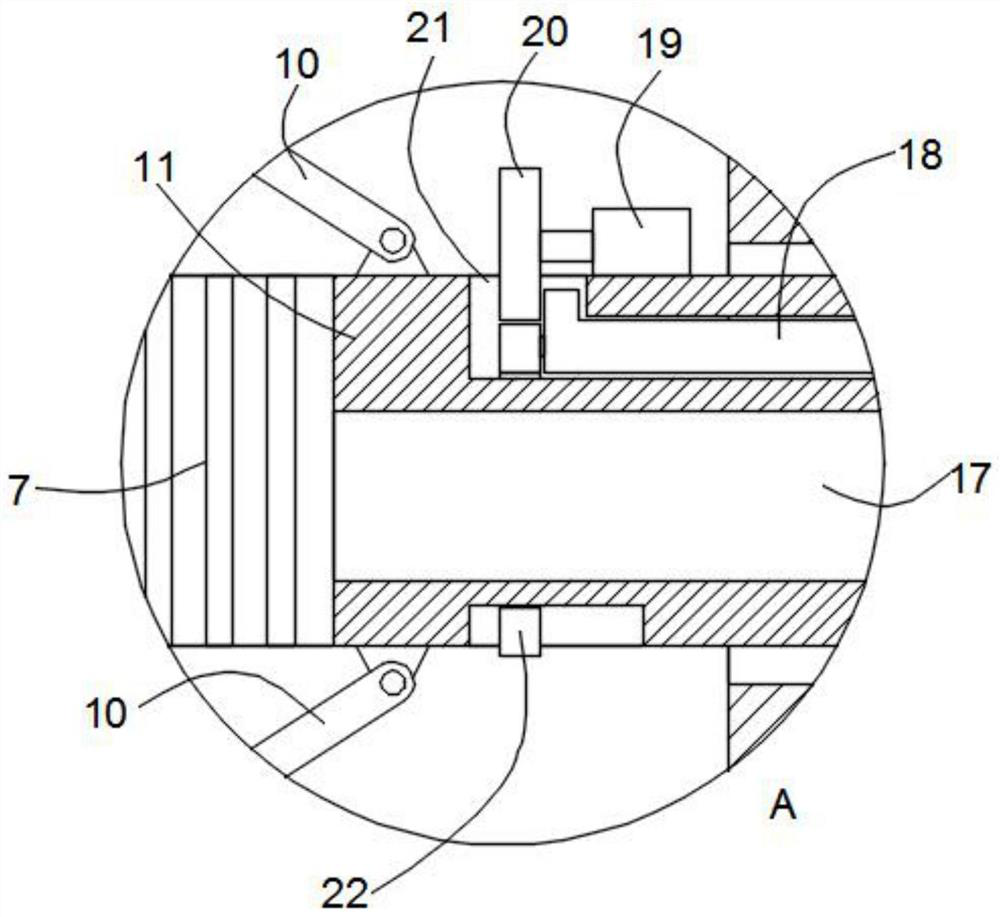

[0031] See Figure 1-5 A secondary salted soil collapsed sampling device comprising a sampling tube 1, the sampling tube 1 is a circular drill rod shape, and the inner coaxial coaxial cohaxing is opened in the coated cavity 2, sampling The housing of the tube 1 is distributed axially, and the respective guiding holes 23 of the same loop are uniformly distributed in the circumferential direction.

[0032] The cavity 2 is fixed to the high pressure water pipe 4, and one end of the high pressure water pipe 4 projects the sampling tube 1, and is connected to the liquid pipe 6. Among them, the high pressure water pipe 4 passes through the liquid pipe 6 into the high pressure column, and the intubation 11 in the guide hole 23 is injected into the soil.

[0033] Each of the guiding holes 23 slides inserted with an in-tubing 11, and the high pressure water pipe 4 is connected by the telescoping tube 7, and the other end of the cannula 11 has a tapered structure, an insertion 11 inside. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com