Frost prevention control system

A control system and anti-frost technology, applied in defrosting, household refrigeration devices, coolers, etc., can solve problems such as frosting or fogging, affecting the continuous and effective operation of automation devices, and adverse effects on the quality of stored items, so as to improve intelligence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

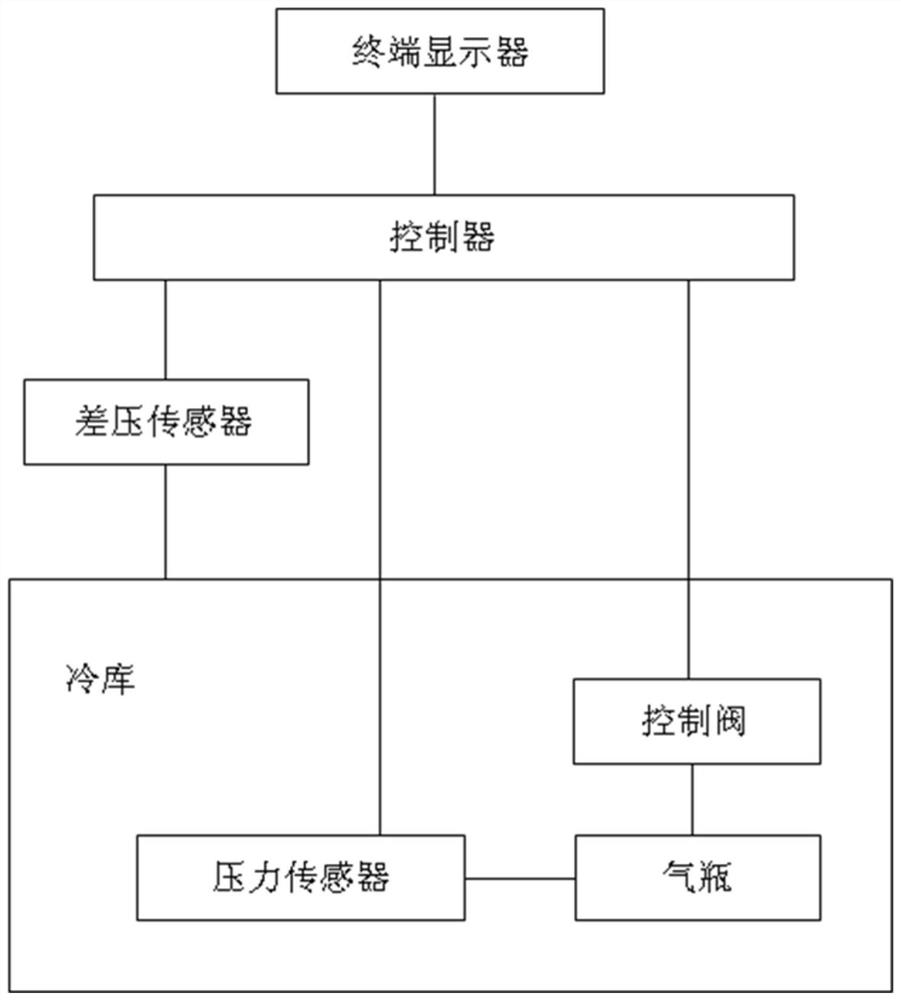

[0055] Such as figure 1 As shown, a frost control system includes a cold storage, a terminal display, a controller, a differential pressure sensor, a pressure sensor group, a control valve group and at least one gas cylinder, and the pressure sensor group includes at least one gas cylinder that matches the number of gas cylinders A pressure sensor, the control valve group includes at least one control valve matching the number of gas cylinders, the pressure sensor group, control valve group and gas cylinders are all arranged inside the cold storage, the gas cylinders are connected to the control valve, The control valve is connected to the controller, the gas cylinder is connected to the pressure sensor, the pressure sensor is connected to the controller, the cold storage is connected to the differential pressure sensor, and the differential pressure sensor is connected to the The controller is connected, and the terminal display is connected to the controller, wherein:

[00...

Embodiment 2

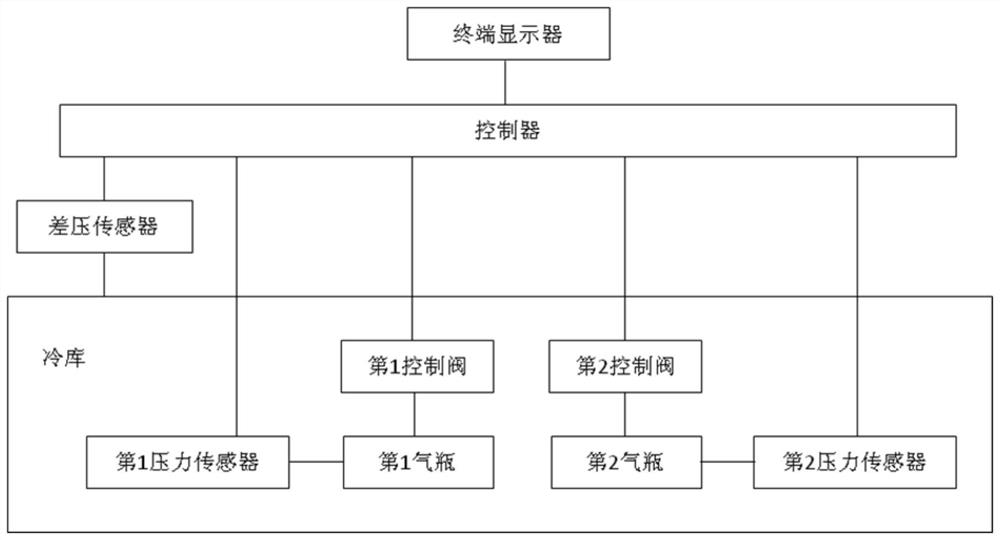

[0063] The number of gas cylinders is N, wherein N is a positive integer greater than 1, and the N gas cylinders are set to be the first gas cylinder to the Nth gas cylinder respectively, and the set pressure sensor group includes pressure sensors corresponding to the N gas cylinders. From the first pressure sensor to the Nth pressure sensor, the control valve group includes the control valves corresponding to the N gas cylinders as the first control valve to the Nth control valve;

[0064] The first to Nth pressure sensors are respectively used to monitor the pressure of the first to Nth gas cylinders and feed back to the control system, and the control system receives the current pressure of the first to Nth gas cylinders. Pressure value;

[0065] The control system arranges the set form according to the received current pressure values of the N gas cylinders, and the set form arrangement can be arranged in ascending order or descending order of the pressure values;

[00...

Embodiment 3

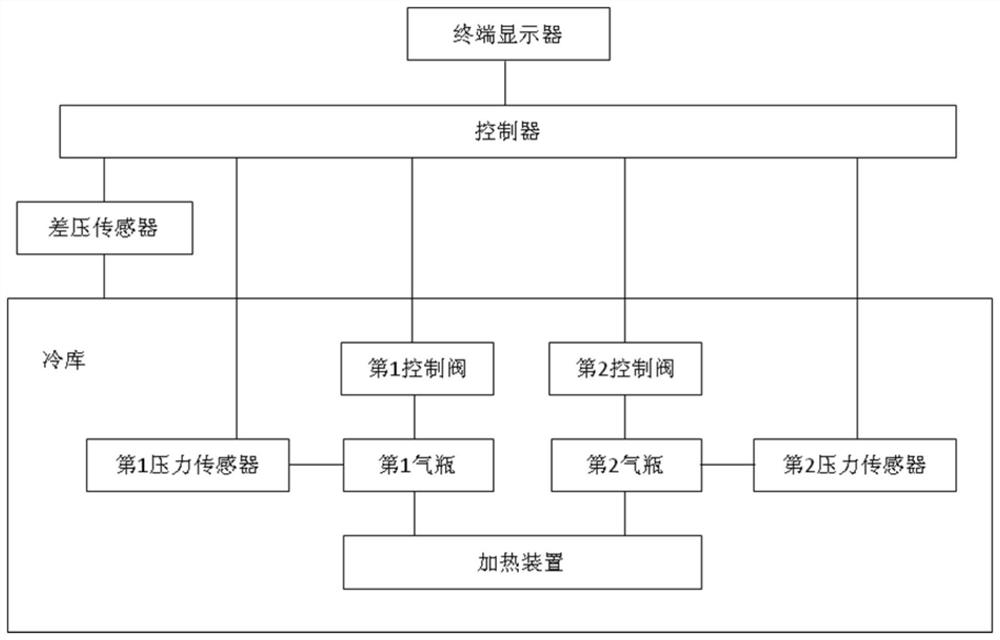

[0071] In this embodiment, when the controller receives that the current pressure value of the priority compensation gas cylinder reaches the second set value, the controller performs setting according to the received current pressure value of the N gas cylinders. Arrangement in a certain form, and reset the priority compensation cylinders in the current state.

[0072] It should be noted that, in this technical solution, when the controller receives that the current pressure value of the priority compensation gas cylinder reaches the second set value, the controller generates a third instruction, and sends a message to the terminal display Send the third command to remind the user that the gas cylinder is insufficient and needs to be replaced, indicating that the priority compensation gas cylinder can no longer be used to replenish and deliver gas to the cold storage. The current pressure value of the gas cylinder is arranged again in a new setting form (the meaning of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com