Anti-blocking deslagging structure of circulating fluidized bed boiler

A circulating fluidized bed and boiler technology is applied in the field of anti-blocking and slag discharge structure of circulating fluidized bed boilers, which can solve the problems of poor slag discharge, large operation loss of bed materials, affecting the normal operation of the boiler, etc., and achieve smooth slag discharge from the boiler. , The effect of promoting slag discharge and avoiding excessive carbon content in slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

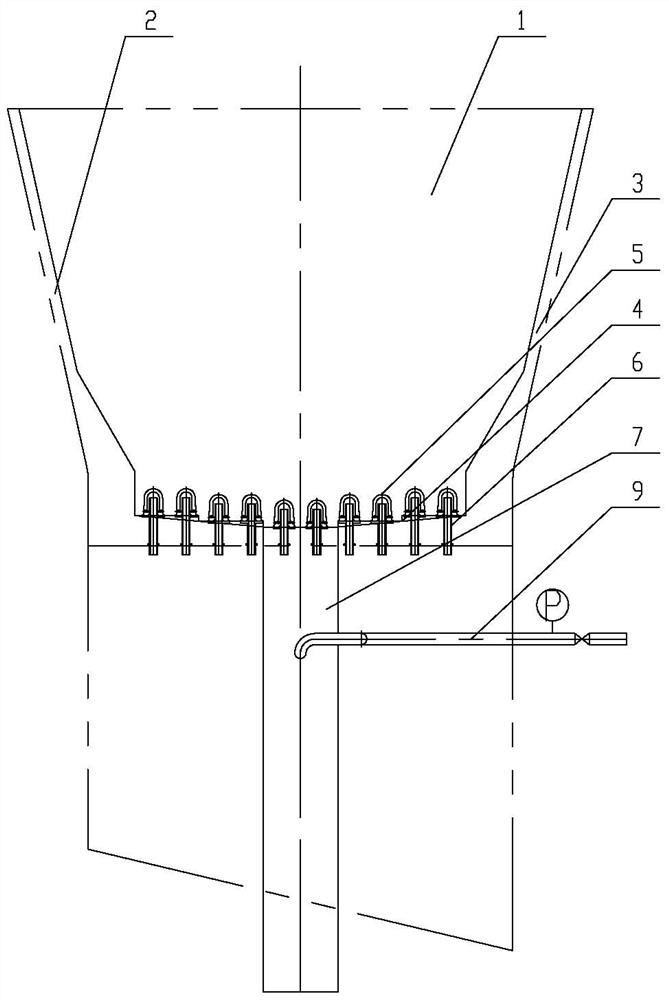

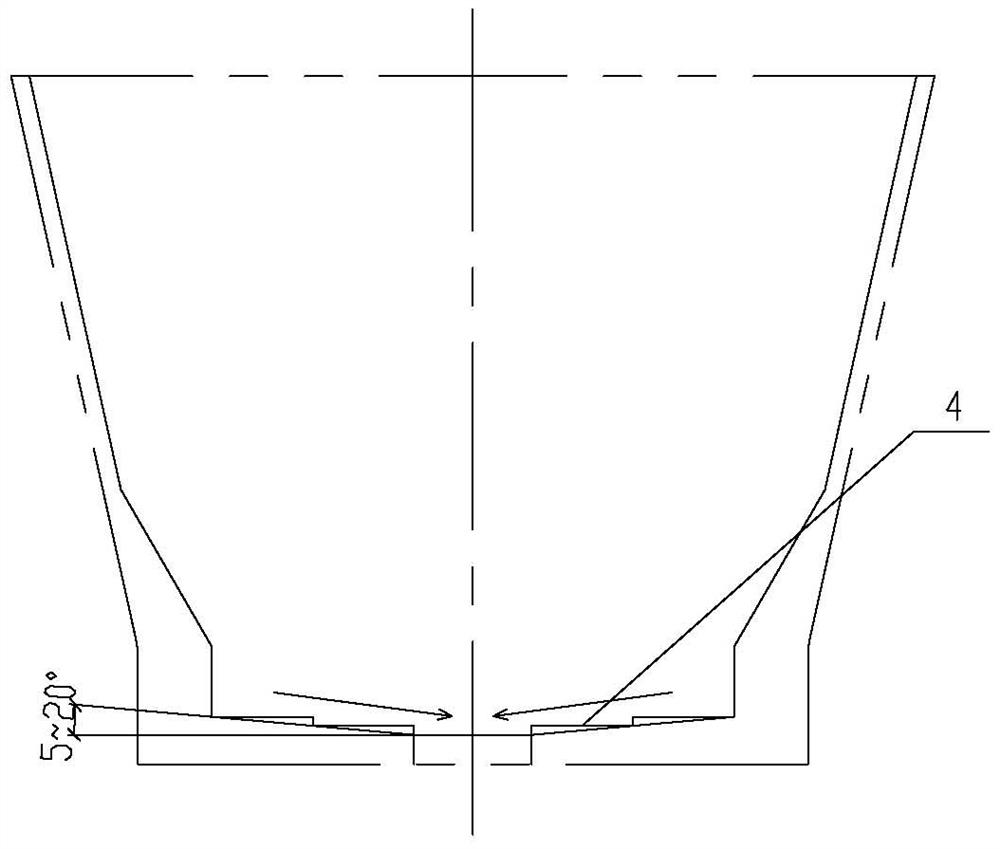

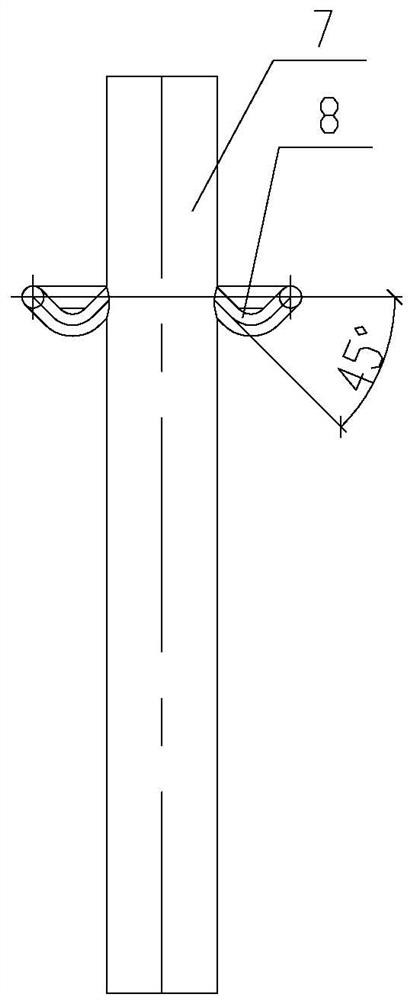

[0018] See Figure 1 to Figure 6 As shown, a circulating fluidized bed boiler anti-blocking slagging structure, which includes a furnace 1, figure 1 The positions of the furnace front wall 2 and the furnace rear wall 3 are marked in the middle, the bottom of the furnace 1 is provided with an air distribution plate 4, the air distribution plate 4 is equipped with a connecting pipe 6 with a hood 5, and the center of the air distribution plate 4 is provided with a slag outlet. The slag outlet is connected to the slag pipe 7, and the slag pipe 7 is a square heat-insulated slag pipe. For the convenience of description, the side of the slag pipe 7 parallel to the front side and the rear side of the furnace is taken as the width of the slag pipe, and the slag pipe 7 and the The parallel sides on the left and right sides of the furnace are used as the length of the slag pipe, and the length: width is usually 400:200 or 400:300, etc. The ratio can be adjusted according to the actual s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com