Fuel cell cold starting system and method and vehicle

A fuel cell and cold start technology, applied in fuel cells, power system fuel cells, electric vehicles, etc., can solve the problems of insufficient ice breaking capacity of the compressed valve, failure of the cold start of the fuel cell, and failure of the air compressor to start, etc. Successful cold start, meet the needs of vehicles in low temperature environment, and facilitate the effect of large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

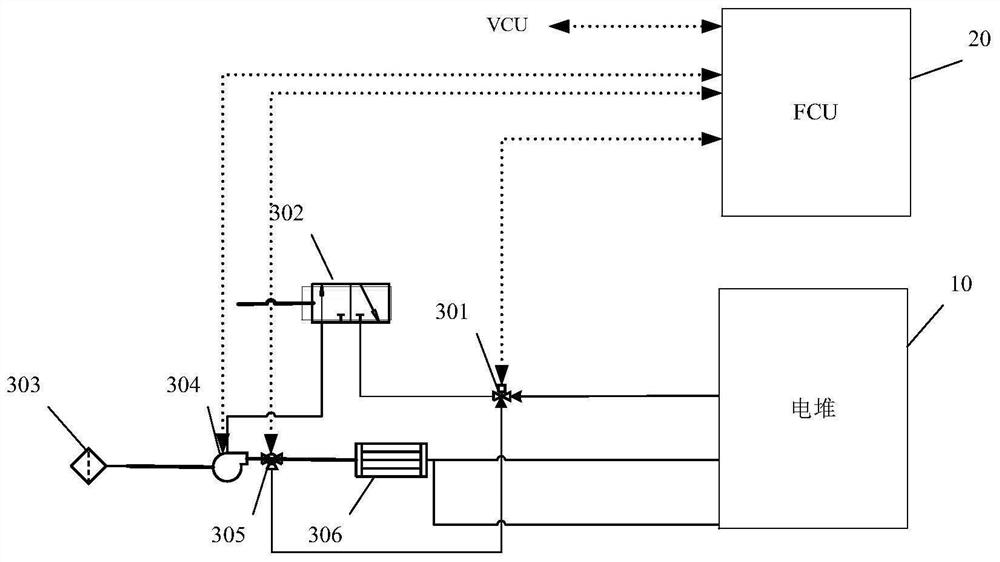

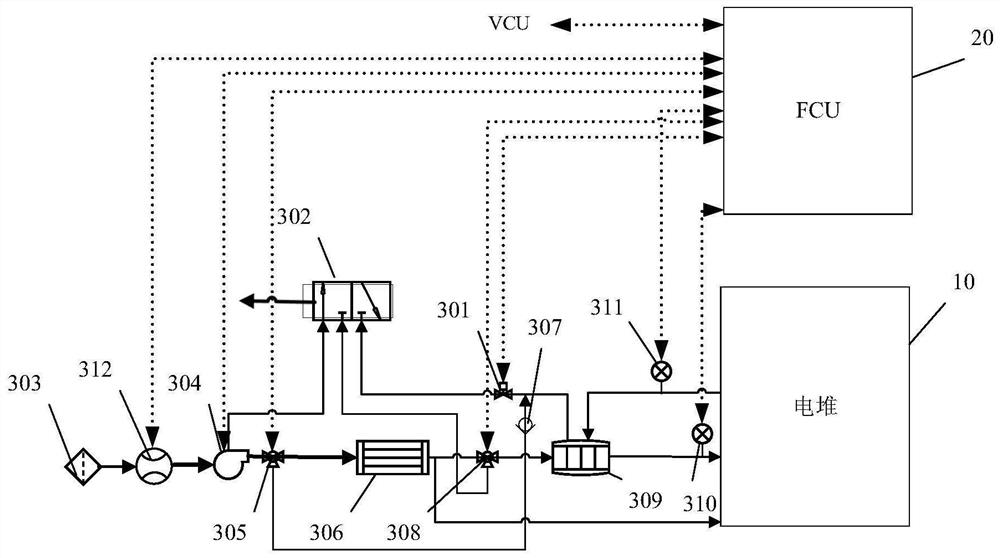

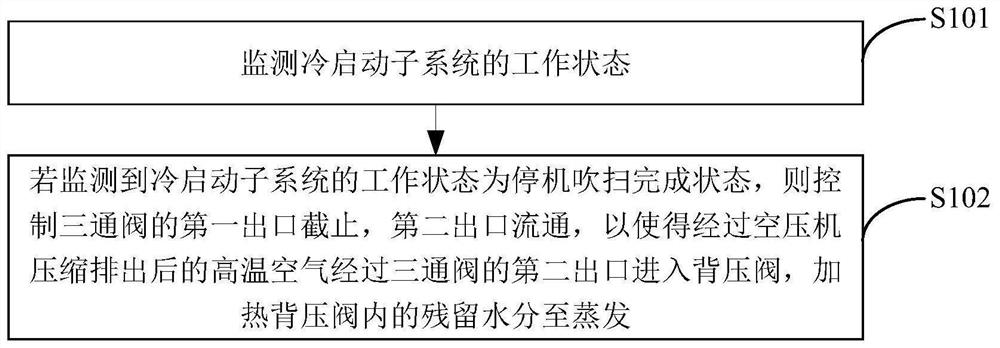

[0029] Embodiments of the present application provide a fuel cell cold start system, method, and vehicle. The system can effectively reduce the moisture residue in the back pressure valve, so as to prevent the back pressure valve from freezing during the cold start of the fuel cell system, causing the back pressure valve to freeze. The opening of the pressure valve can be adjusted normally, and then the air compressor can be started smoothly to ensure the successful cold start of the fuel cell.

[0030] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0031] It should be noted that the shutdown purging mentioned in this application means that the stack is purged with air to remove internal moisture after shutdown, and the completion of shutdown purge refers to the completion of the purge action of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com