Explosion door of micro-positive pressure flue gas and air system

An explosion-proof door, micro-positive pressure technology, applied in safety valves, engine components, balance valves, etc., can solve problems such as difficulty in high-altitude operations, increased safety risks, increased maintenance workload, and difficulty in disassembling flange bolts. The effect of simplifying the maintenance operation process and operation difficulty, controlling operation risks, and reducing the frequency of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

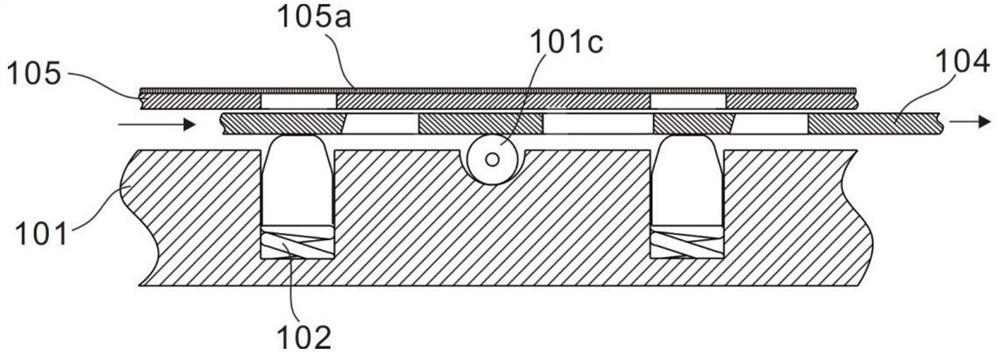

[0028] refer to Figure 1 ~ Figure 3 , which is the first embodiment of the present invention, this embodiment provides a kind of explosion-proof door of the micro-positive pressure smoke system, and the explosion-proof door of the micro-positive pressure smoke system includes a sealing assembly 100 and a blasting element 200 .

[0029] Specifically, the sealing assembly 100 includes a bottom plate 101, a spring 102, permanent magnet particles 103, and a silicon steel sheet 104. The bottom plate 101 is an annular thick steel plate with a circular groove 101a on the surface. The spring 102 is arranged in the circular groove 101a, and the permanent magnet The particles 103 are arranged above the spring 102 to absorb the blasting element 200. The silicon steel sheet 104 is ring-shaped and arranged above the bottom plate 101, which can shield or release the magnetism of the permanent magnet particles, so that the replacement of the old blasting element and the sealing surface The ...

Embodiment 2

[0032] refer to Figure 1 ~ Figure 4 , is the second embodiment of the present invention, which is based on the previous embodiment.

[0033] Concretely, on the semiperimeter arc length where the first through hole 104a of the silicon steel sheet 104 is in contact with the permanent magnet particle 103, a tapered surface is made along the thickness direction of the silicon steel sheet 104, and the taper of its projection is consistent with the taper at the top of the permanent magnet particle 103 , when the silicon steel sheet 104 rotates and moves, there is a downward pressure on the permanent magnetic particle 103 on the conical surface, so that the permanent magnetic particle 103 compresses the spring 102 in the circular groove 101a, and the part is received in the circular groove 101a, and the silicon steel sheet 104 The first through hole 104a passes through the permanent magnetic particles 103 smoothly, and shields the permanent magnetic particles 103 magnetically.

[0...

Embodiment 3

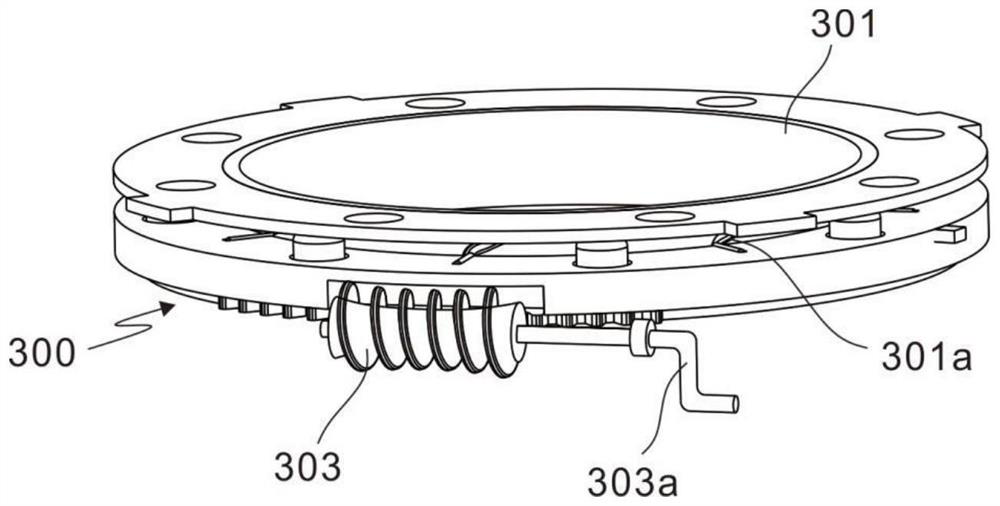

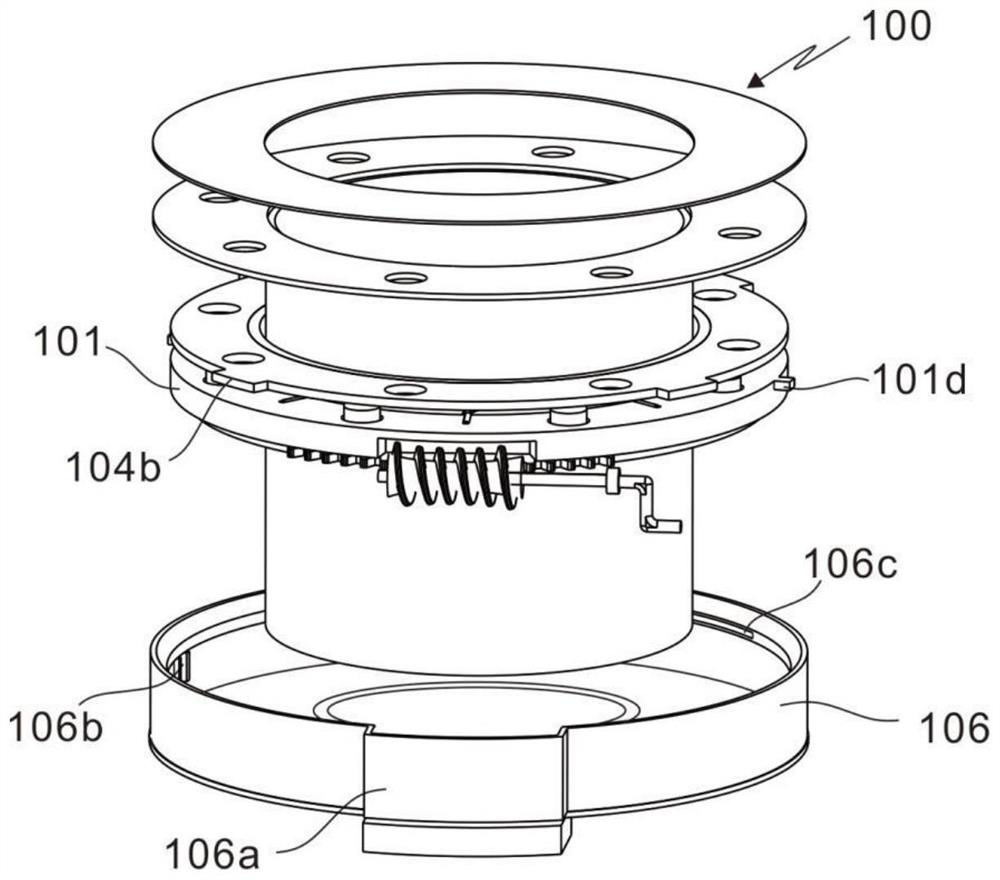

[0040] refer to Figure 3 ~ Figure 6 , is the third embodiment of the present invention, which is based on the first two embodiments.

[0041] Specifically, the sealing assembly 100 further includes a cover plate 105 and a housing 106 . The cover plate 105 is an annular thin steel plate, and its surface is provided with second through holes 105a which are consistent with the number of circular grooves 101a and the center distance of the holes. The surface of the cover plate 105 is provided with a rubber lining layer 105b, and the permanent magnetic particles 103 pass through the first through holes. 104a and the second through hole 105a absorb the blasting element 200, and the thickness of the rubber lining layer 105b is moderate, and its thickness range can take into account both magnetic permeability and sealing performance, and is made of fluororubber material with high temperature resistance, aging resistance and corrosion resistance; and, the shell 106 is disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com