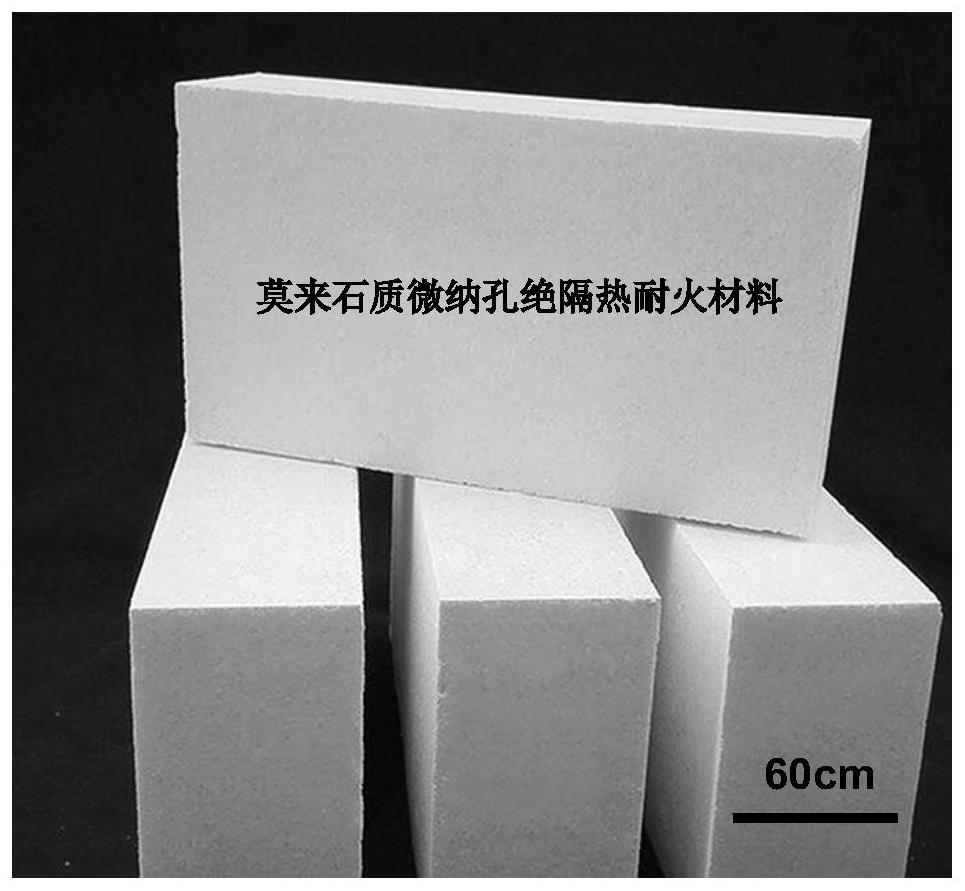

Mullite micro-nano pore heat insulation refractory material and preparation method thereof

A refractory material and micro-nano-pore technology, which is applied in the field of refractory materials, can solve the problems of low thermal conductivity and thermal insulation refractory materials, and achieve the effects of high green body strength, short demoulding and drying cycles, and simple process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

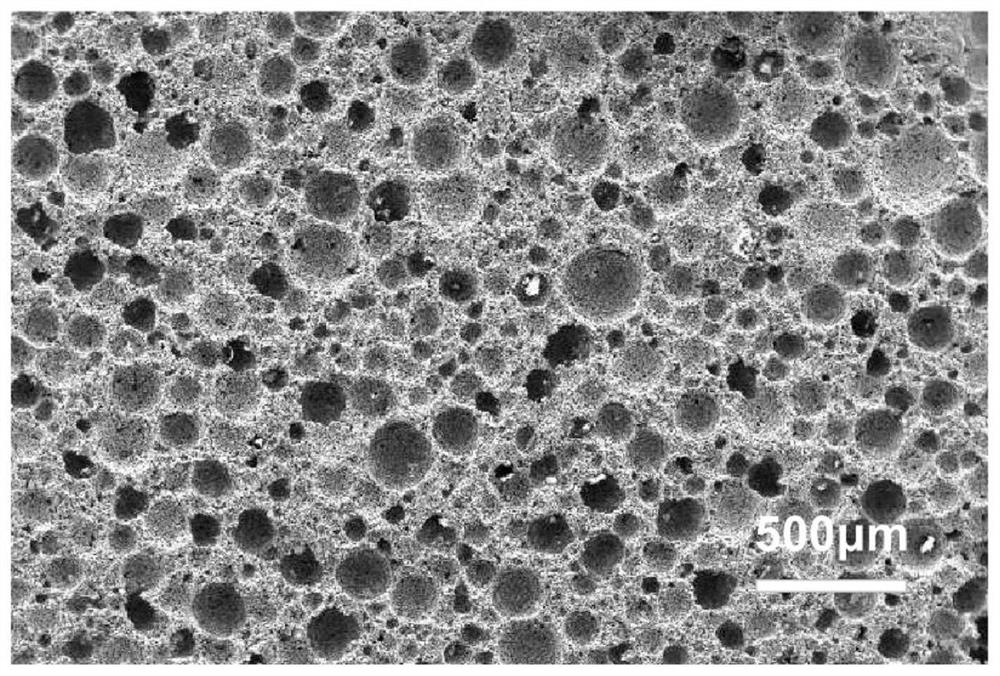

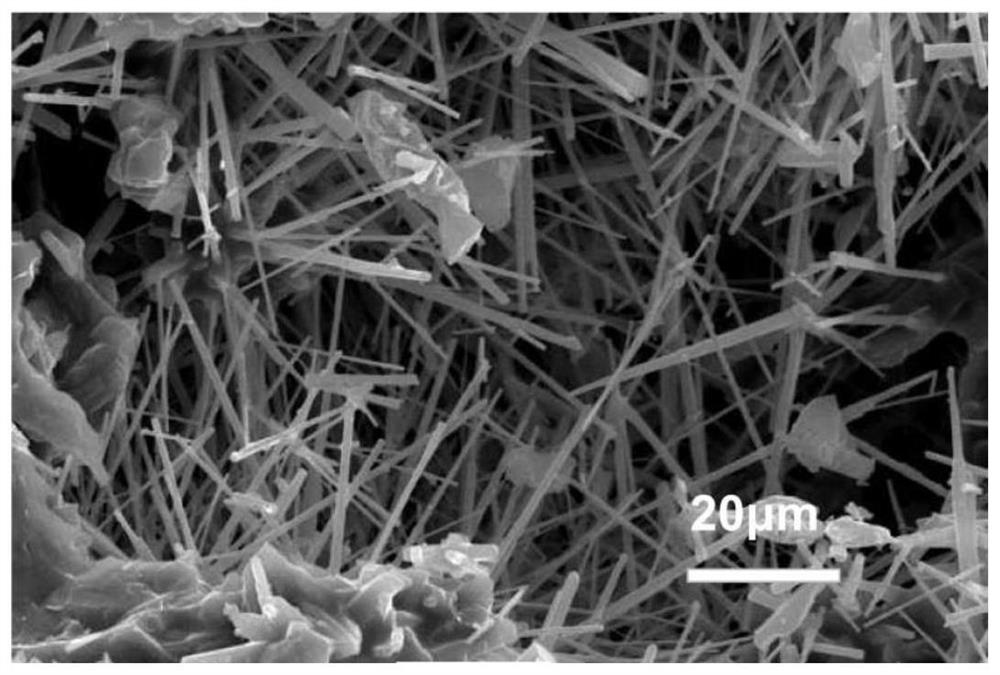

[0095] The mullite micro-nanoporous heat-insulating refractory material in this embodiment has mullite as the main crystal phase, and the shape of mullite is needle-shaped, with a length of 37-45 μm and an aspect ratio of 37-62. The mass percent of alumina in the chemical composition of the product is 25-28%. The product is made of base materials, additives and water, wherein the additives are composed of suspending agent, mineralizer, infrared shading agent, foaming agent, inorganic curing agent, organic curing agent and cell regulator.

[0096] The used base material is composed of the following components in mass percentage: 90% of aluminum-silicon raw material and 10% of silicon dioxide raw material. Among them, the aluminum-silicon raw materials are composed of perlite, potassium feldspar, kaolin (in its chemical composition, Al 2 o 3 The mass percentage is 36-38%, SiO 2 The mass percentage is 54-57%, and the particle size is 0.6-1mm) mixed according to the mass ratio ...

Embodiment 2

[0100] The mullite micro-nanoporous heat-insulating refractory material in this embodiment has mullite as the main crystal phase, and the shape of mullite is needle-shaped, with a length of 32-43 μm and an aspect ratio of 38-64. The mass percentage of alumina in the chemical composition of the product is 25-26%. The product is made of base materials, additives and water, wherein the additives are composed of dispersant, suspending agent, mineralizer, infrared sunscreen agent, foaming agent, inorganic curing agent, organic curing agent and cell regulator.

[0101] The used base material is composed of the following components in mass percentage: 25% of alumina material, 5% of aluminum silicon material, and 70% of silicon dioxide material. Among them, the alumina raw material is a mixture of industrial alumina and diaspore according to the mass ratio of 4:1; the aluminosilicate raw material is made of alkali stone (Al 2 o 3 The mass percentage is 45-48%, SiO 2 The mass percen...

Embodiment 3

[0104] The mullite micro-nanoporous heat-insulating refractory material in this embodiment has mullite as the main crystal phase, and the shape of mullite is needle-shaped, with a length of 41-53 μm and an aspect ratio of 39-72. The mass percent of alumina in the chemical composition of the product is 31-33%. The product is made of base materials, additives and water, wherein the additives are composed of dispersant, suspending agent, mineralizer, infrared sunscreen agent, foaming agent, inorganic curing agent, organic curing agent and cell regulator.

[0105] The used base material is composed of the following components in mass percentage: 10% of alumina material, 80% of aluminum silicon material, and 10% of silicon dioxide material. Among them, the alumina raw material is γ-Al 2 o 3 , the aluminum siliceous raw material is composed of fly ash, floating beads, kaolin (Al 2 o 3 The mass percentage content of 32 ~ 35%, SiO 2 The mass percentage content is 61-64%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com