Automobile air inlet pipe injection mold easy to demold

A technology for injection molds and air intake pipes, which is applied to household appliances, tubular items, other household appliances, etc., can solve problems such as difficulty in demoulding, influence on the quality of injection molded parts, and reduce product qualification rate, and achieve easy demoulding and good use efficiency. , The effect of improving the efficiency of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

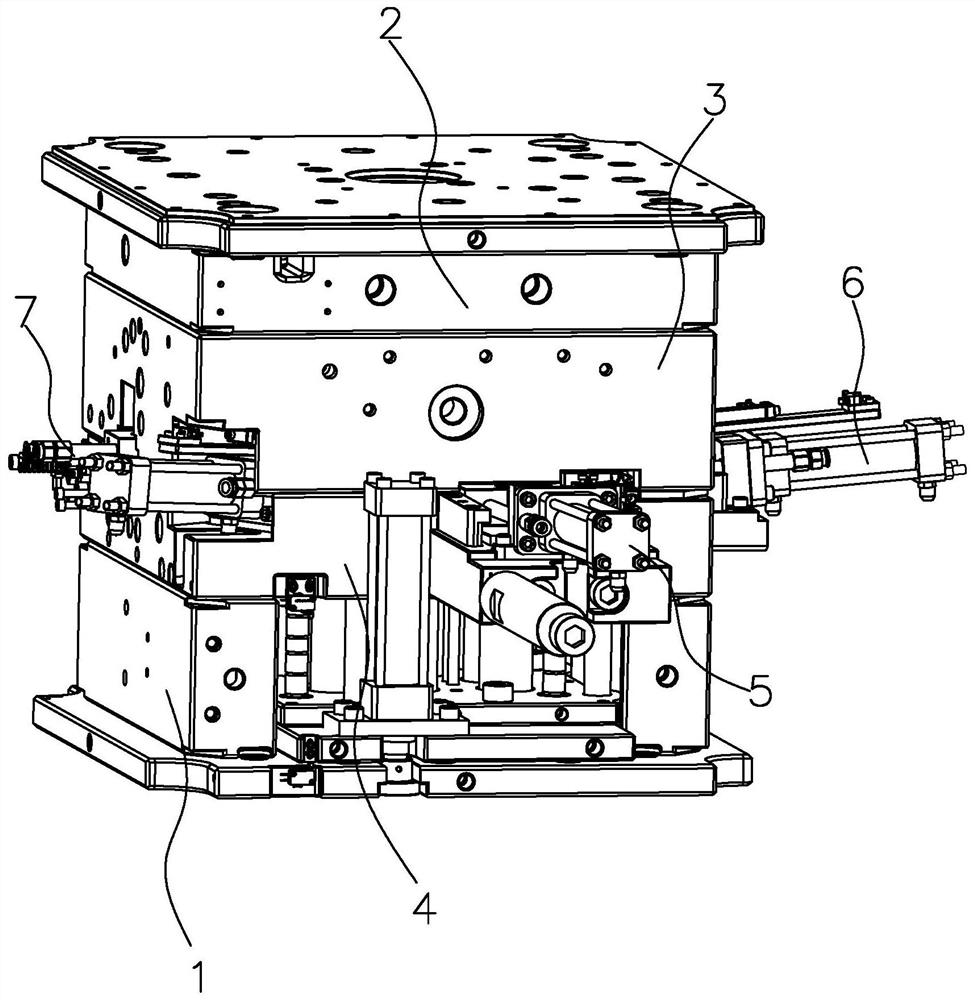

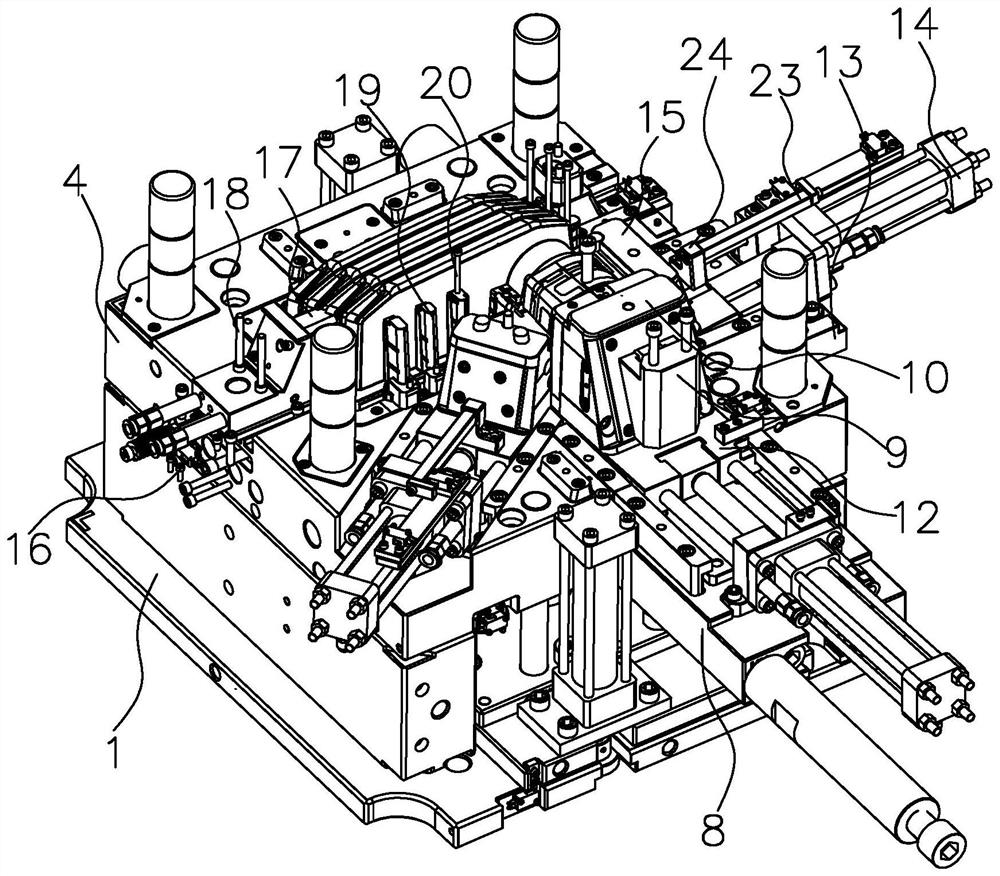

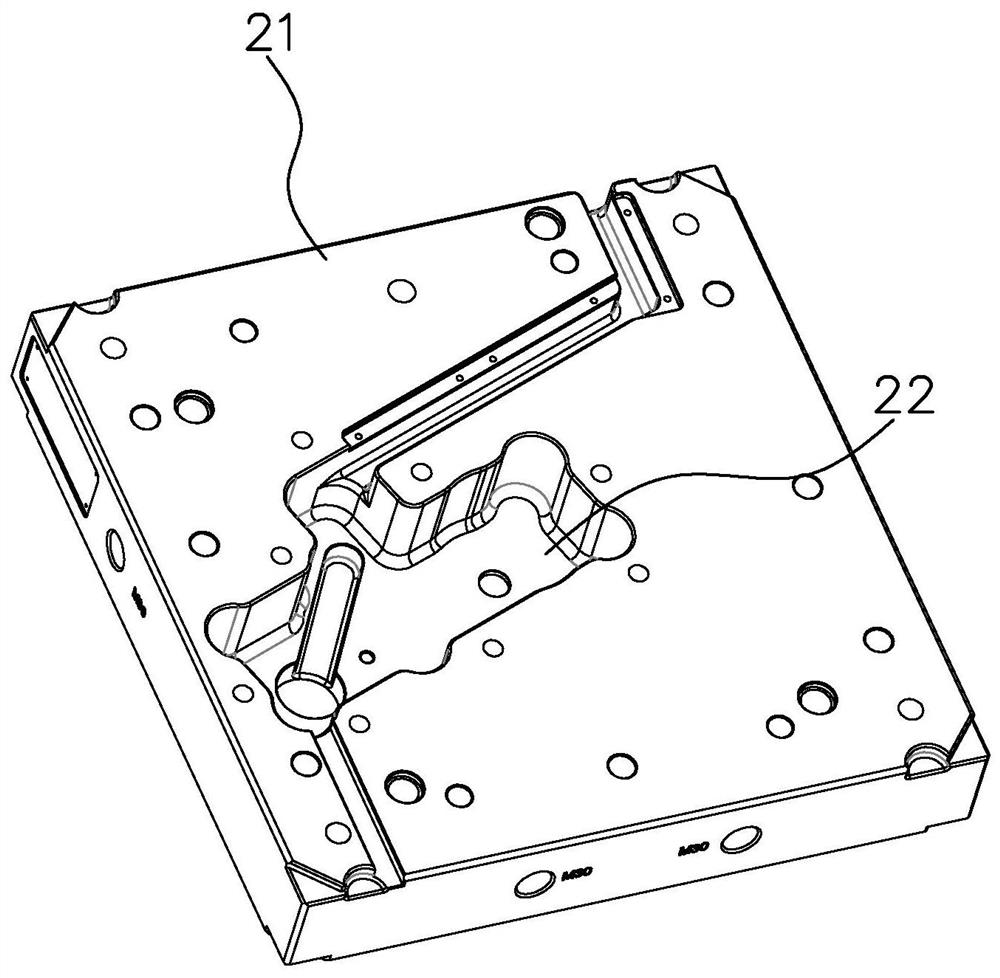

[0039] An injection mold for an easy-release automobile intake pipe, such as Figure 1 to Figure 4 As shown, it includes: an upper mold base 1; a lower mold base 2 arranged opposite to the upper mold base 1; an injection molding plate for injection molding of the intake pipe, and the injection molding plate includes: an upper injection molding plate 3, and an upper injection molding plate The lower injection molding plate 4 arranged in cooperation with the plate 3; the injection ejection mechanism positioned on the lower injection molding plate 4 for injection molding the intake pipe, the injection ejection mechanism includes: the main ejection mechanism 5, and the auxiliary ejection mechanisms located on both sides of the main ejection mechanism 5 6. And the auxiliary fixed push-out mechanism 7 located on the side of the auxiliary push-out mechanism 6, the main push-out mechanism 5 is used to shape the mouth of the intake pipe; and the injection molded stabilizer used to stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com