Tool path generation method and device capable of automatically recognizing groove features and storage medium

A technology of automatic identification and groove features, applied in the field of turning processing, can solve the problems of reduced work efficiency, time-consuming, cumbersome operation of manual selection of groove features, etc., to reduce workload, reduce drawing or selection, and improve programming work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

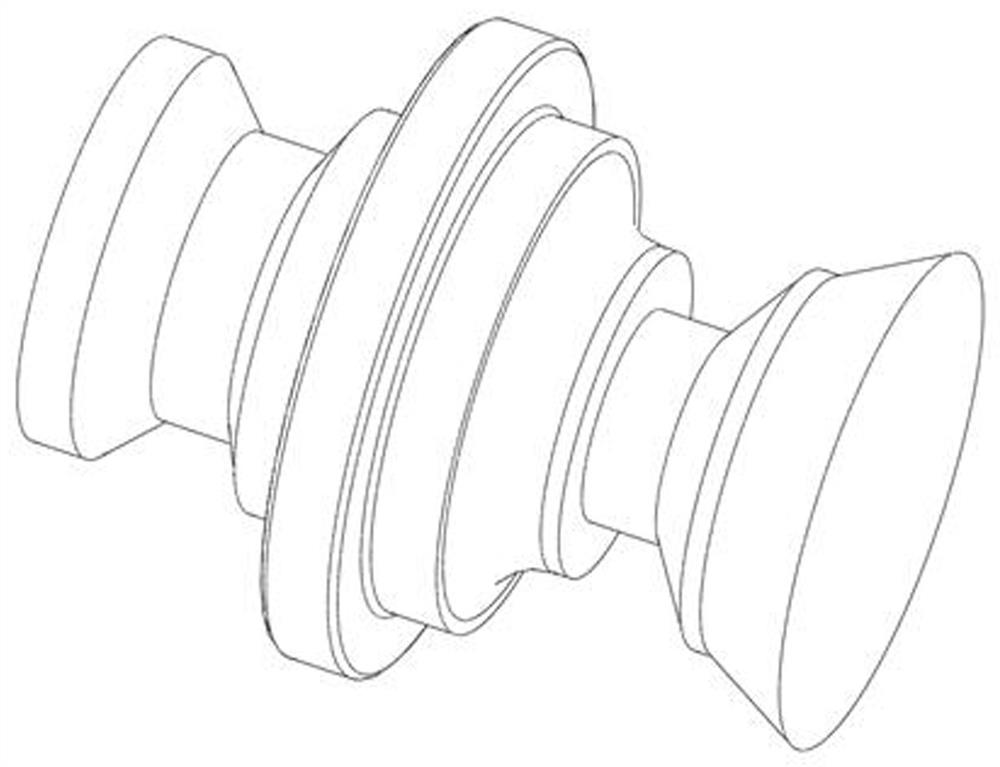

[0044] This embodiment provides a knife rail generation method for automatic identification slot feature, and the part is trough to obtain a corresponding groove trajectory, which reduces the operation of the user manually draw or selects the characteristics of the slot, reducing the user's workload, and improve programming Work efficiency.

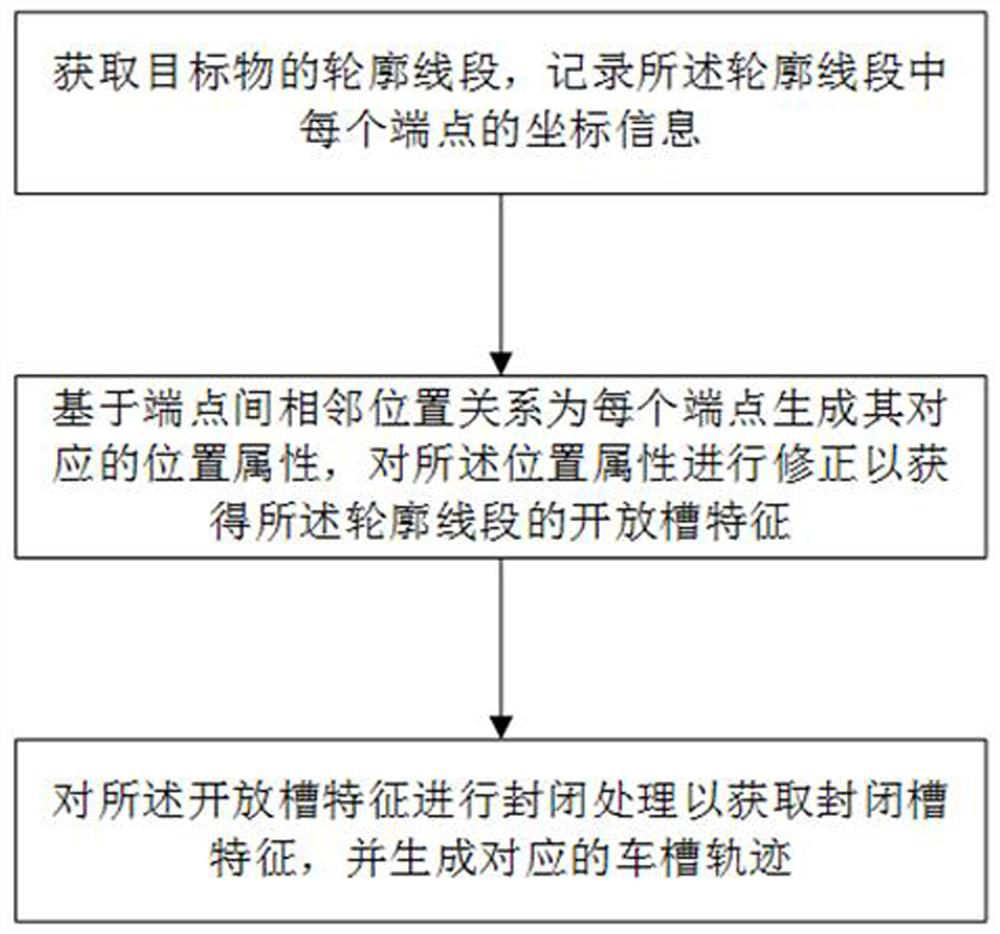

[0045] Such as figure 1 , Figure 10 As shown, the method of identifying tank features in this embodiment includes the steps of:

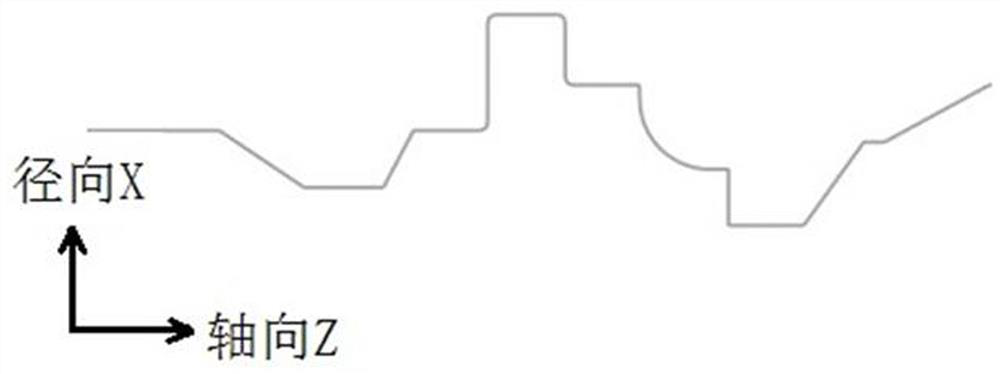

[0046] Step S1: Obtain the outline segment of the target, record the coordinate information of each endpoint in the outline segment;

[0047] Step S2: Based on the adjacent position relationship between the endpoints, each end point generates its corresponding position attribute, correcting the position attribute to obtain open slot characteristics of the outline segment;

[0048] Step S3: The open slot feature is closed to acquire the closed groove characteristics, and the corresponding groove trajectory is genera...

Embodiment 2

[0077] This embodiment provides an electronic device comprising a processor, a memory, and a computer program stored on the memory and can run on the processor, the processor implements the computer program. Automatic identification slot feature knife rail generation method; further, the present embodiment also provides a storage medium that stores a computer program that implements the above-described automatic identification slot feature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com