Patch device and automatic patch method

A patch device and patch technology, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of labor resource consumption and low production efficiency, and achieve the effects of convenient work, increased success rate, and high replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

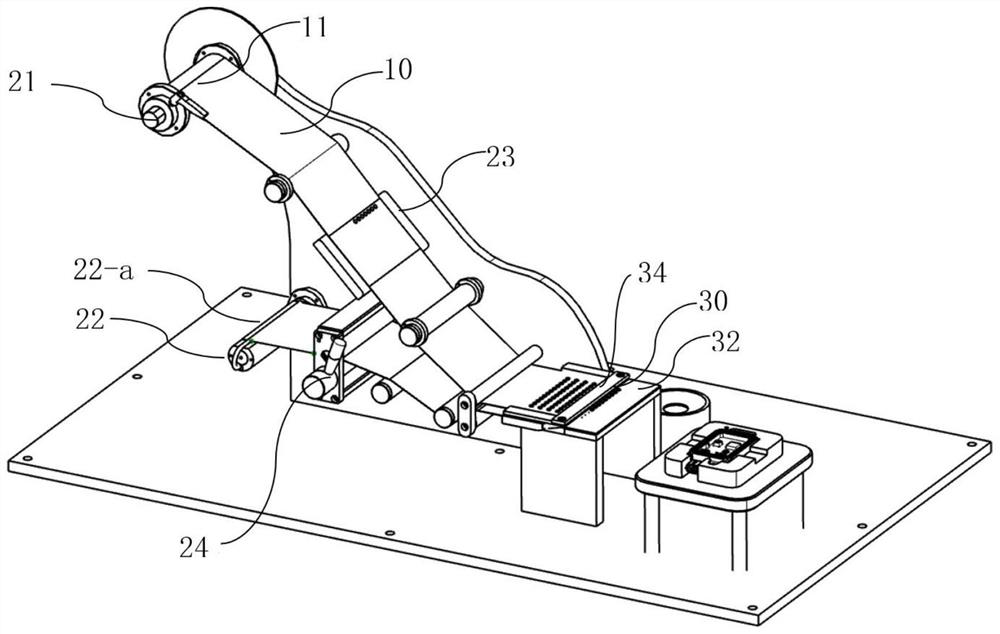

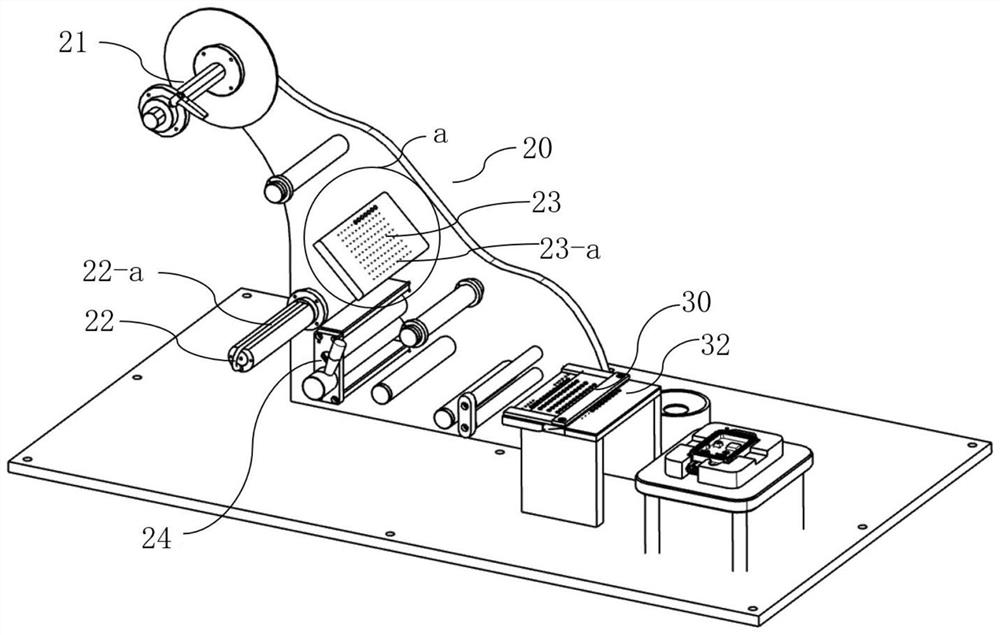

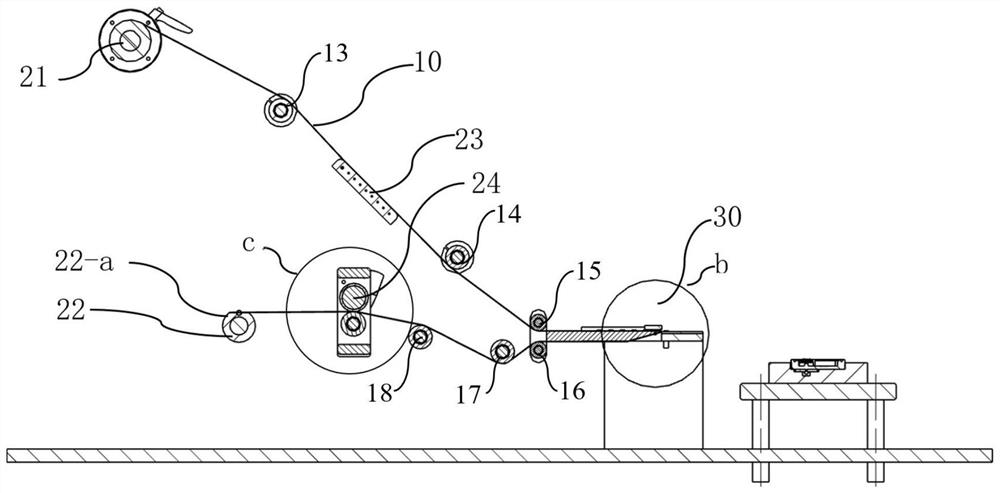

Embodiment 1

[0067] This embodiment is a patch device, such as Figure 7 As shown, this placement device comprises: feeding mechanism 20, unloading mechanism 30 and material taking mechanism 40. The device can paste the patch 12 to the object to be pasted. The patch 12 is a soft and thin piece with stickiness on one side, such as the air-permeable sticker used on the car radar casing, or the film on the back cover of the mobile phone and other parts. Such as figure 1 As shown, the patch 12 is pasted on the surface of the material tape 10 before the patch 12 and the object to be pasted are processed into a finished product, and the material tape 10 pasted with the patch 12 is wound on the surface of the reel 11, which is convenient for transportation and sale .

[0068] What is different from ordinary conveyor belts is that the patch 12 itself is sticky and cannot fall out of the material belt by gravity. But patch 12 has certain intensity and length again, so the present invention has u...

Embodiment 2

[0075] This embodiment is a patch device. This embodiment includes the feeding mechanism 20, the unloading mechanism 30 and the retrieving mechanism 40 in the first embodiment, and optimizes different mechanisms to achieve different technical effects. The same parts I won't repeat them here.

[0076] Specifically, the working surface 38 of the anti-adhesive plate 32 is lower than the first sliding surface 31-a, and the success rate of peeling off the patch 12 is improved by forming a drop between the anti-adhesive plate 32 and the first sliding surface 31-a. The surface of the first sliding surface 31-a is equipped with a pressing plate 34, and there is a second gap 35 between the pressing plate 34 and the surface of the first sliding surface 31-a, and the second gap 35 is greater than the sum of the thickness of the strip 10 and the thickness of the patch 12 , and leave a certain safety distance. Insufficient bonding of the patch 12 and the tape 10 is prevented, causing the ...

Embodiment 3

[0086] This embodiment is a patch device. This embodiment includes the feeding mechanism 20, the unloading mechanism 30 and the retrieving mechanism 40 in Embodiment 1 and Embodiment 2, as well as their specific structures. On this basis, this embodiment adds The detection mechanism 50 is provided, and the same parts will not be repeated here.

[0087] Specifically, the detection mechanism 50 includes a first probe 51 and a second probe 52. The first probe 51 is installed on one side of the adsorption column 41, and the sensing direction is toward the surface where the working surface 38 is located, and is used to detect the surface of the patch 12 on the working surface 38. The arrangement on the surface; the second probe 52 is lower than the plane where the working surface 38 is located, and the sensing direction faces the plane where the working surface 38 is located, and is used to detect the arrangement of the patch 12 on different adsorption columns 41 .

[0088] In prac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com