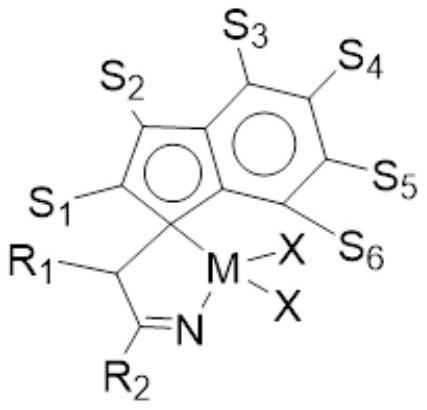

Ligand and preparation method thereof, olefin polymerization catalyst and preparation method and application thereof

A technology of catalysts and ligands, which is used in ligands and their preparation, olefin polymerization catalysts and their preparation. The catalyst is used in the field of catalytic olefin polymerization, which can solve the problem of low insertion rate, low polymerization activity, poor thermal stability of catalysts, etc. problems, achieve different performance, high insertion rate, and maintain high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0073] Example L, ligand Indch 2 (T-bu) C = NH (ligand 1) synthesis

[0074]

[0075] (a) under a nitrogen atmosphere, dissolved in fluid (200 mmol) in 500 ml of anhydrous THF, -45 ° C, adding n-butyllithium (300 mmol), gradually increased to room temperature, stirring at room temperature overnight, filtered, and water with no water The n-hexane was washed three times to obtain a lithium salt of indole: Indli.

[0076] (b) Under the nitrogen atmosphere, lithium salt Indli (125 mmol) was added to 500 ml of anhydrous THF, and 1-bromo-3,3-dimethyl-2-butanone BR was added dropwise under -45 ° C. CH 2 (T-bu) C = O (100 mmol), after the end of the drop, gradually increased to room temperature, and continued to react 2H, filtered, remove the solvent under reduced pressure, and purified with column chromatography to obtain an intermediate.

[0077] (c) The intermediate (50 mmol) was dissolved in tetrahydrofuran (200 mL), and the stirring was added to the system to add ammonium chlorid...

Example Embodiment

[0078] Example 2, ligand CH 3 Indch 2 (T-bu) C = NH (ligand 2) synthesis

[0079]

[0080] (a) under a nitrogen atmosphere, the methacole (200 mmol) was dissolved in 50 ml of anhydrous THF, and the n-butyl lithium (200 mmol) was added dropwise, gradually increased to room temperature, stirred at room temperature overnight, filtered, and used Unhydrated n-hexane washing three times to obtain a lithium salt of methylpase: CH 3 Indli.

[0081] (b) Under the nitrogen atmosphere, the lithium salt of methylline 3 Indli (110mmol) was added to 50 ml of anhydrous THF, and 1-bromo-3,3-dimethyl-2-butanone BR was added dropwise under -45 ° C. CH 2 (T-bu) C = O (100 mmol), gradually increased to room temperature after the dropwise addition, stirred at room temperature for 2 h, filtered, removed the solvent under reduced pressure, and purified by column chromatography to obtain an intermediate.

[0082] (c) The intermediate (50 mmol) was dissolved in tetrahydrofuran (200 mL), and the stirri...

Example Embodiment

[0083] Example 3, ligand Ind (me) CH (T-bu) C = NH (ligand 3) synthesis

[0084]

[0085] (a) under a nitrogen atmosphere, lyal (200 mmol) was dissolved in 50 ml of anhydrous THF, and n-butyl lithium (160 mmol) was added dropwise, gradually increased to room temperature, stirred at room temperature overnight, filtered, and water with no water The n-hexane was washed three times to obtain a lithium salt of indole: Indli.

[0086] (b) Under a nitrogen atmosphere, a lithium salt Indli (100 mmol) of nitrogen was added to 500 ml of anhydrous THF, and 2-bromo-4-dimethyl-3-pentanone Br (ME) was added dropwise under -45 ° C. CH (T-bu) C = O (150 mmol), gradually increased to room temperature after completion of the dropwise, stirred at room temperature for 2 h, filtered, evaporated.

[0087] (c) The intermediate (50 mmol) was dissolved in tetrahydrofuran (200 mL) and ammonium chloride (40 mmol), water (100 ml) was added to the system. The system temperature was raised to 60 ° C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com