Preparation method of organic fertilizer and fermentation tank

The technology of organic fertilizer and fermentation tank, which is applied to the preparation method of organic fertilizer and the field of fermentation tank, can solve the problems of long fermentation time and slow production efficiency of organic fertilizer, and achieve the effects of convenient operation, simple structure and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of organic fertilizer, comprising the following preparation steps:

[0048] S1, ingredients, weigh 1.5t of sludge, 2.5t of edible fungus residue, 1.5t of pig manure, and 0.5t of biochar raw materials, and mix them evenly to obtain a premix;

[0049]S2, premix treatment, drying the premix, adjusting the moisture content of the premix to 65%, adding 0.01t of thermophilic fermentation bacteria to obtain the preparation;

[0050] S3, preparation of organic fertilizer, pour the prepared material into the fermenter, ventilate at intervals, and keep the stirring speed at 3rpm, control the temperature in the fermenter at 80°C, and react for 24 hours to obtain the organic fertilizer;

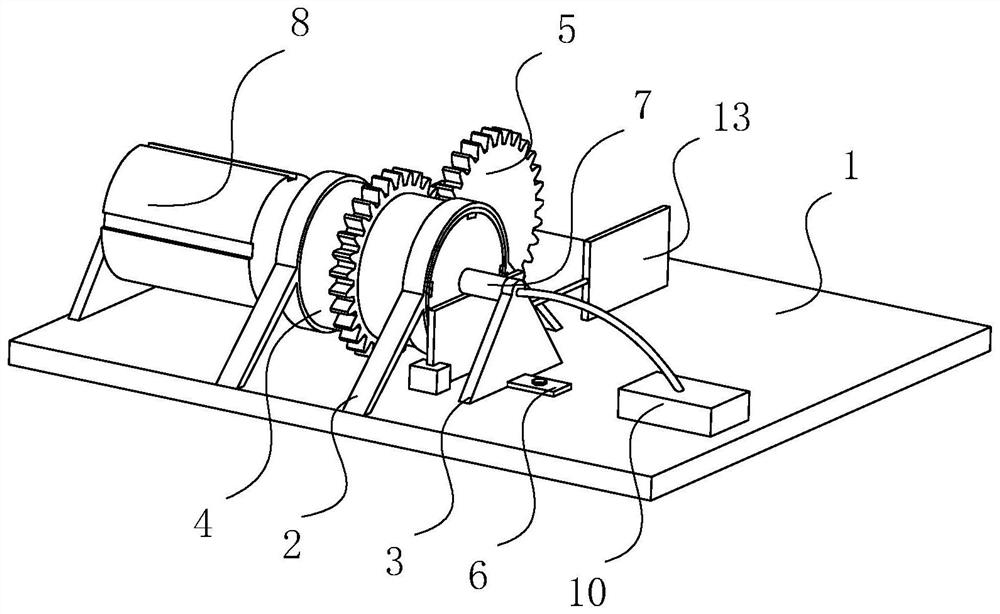

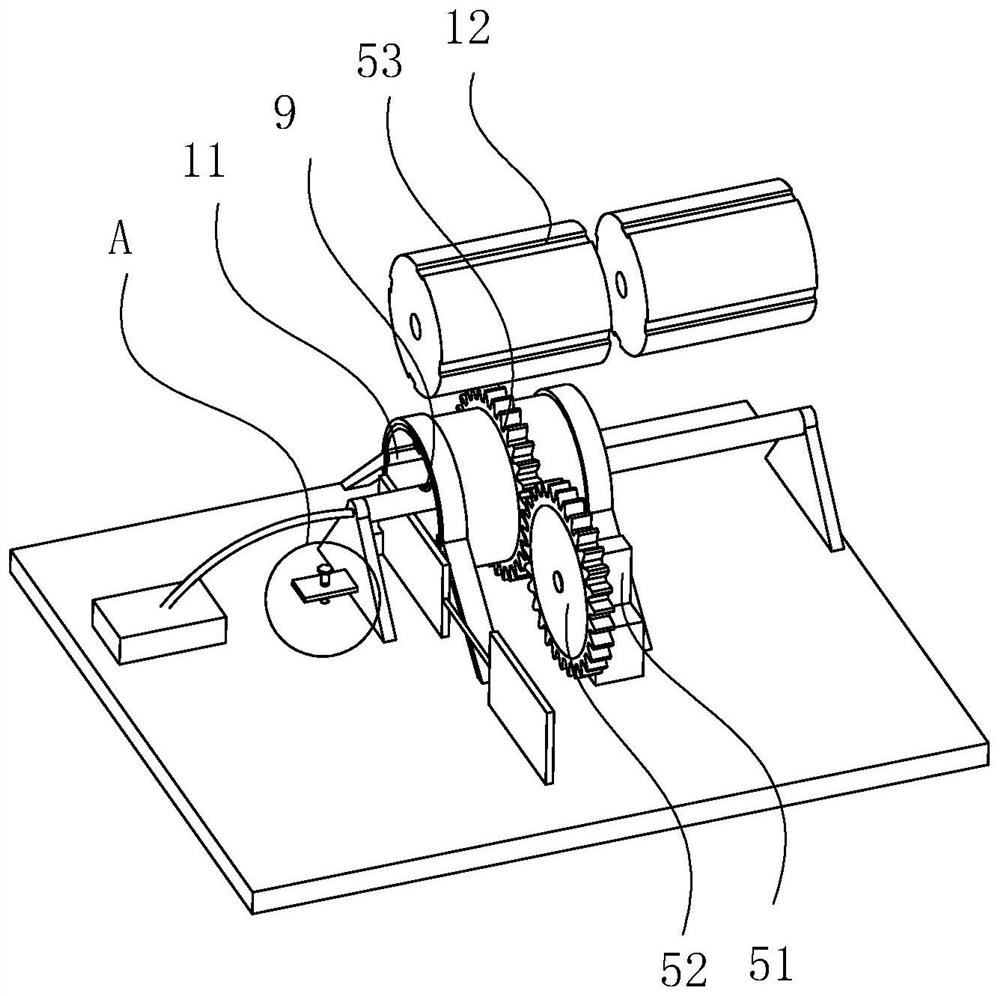

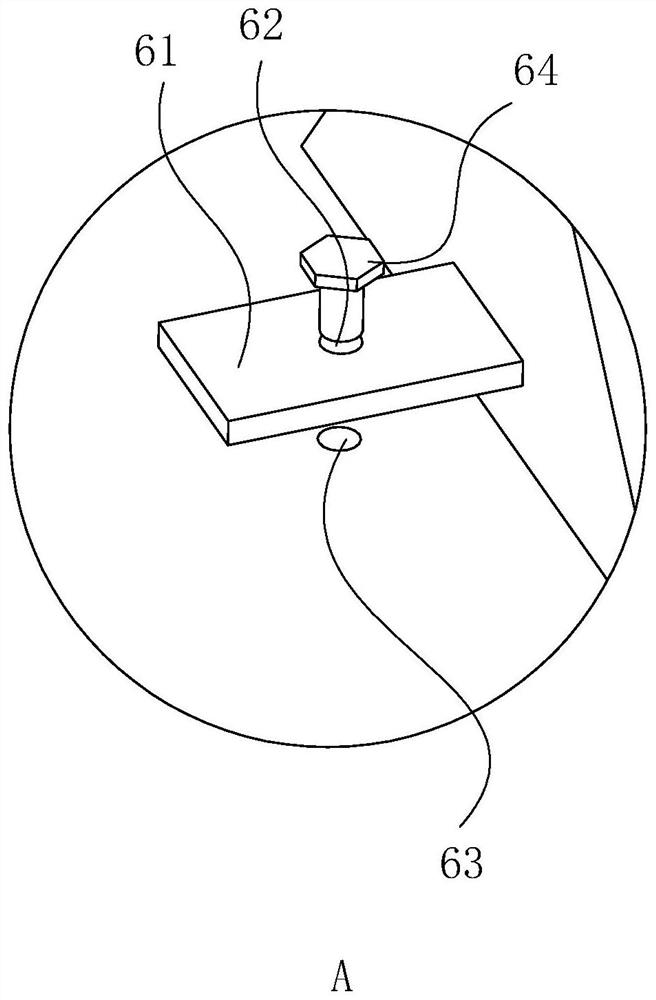

[0051] In step S3, the fermenter is as figure 1 As shown, it includes a base 1, a mounting frame 2 and a sliding frame 3, the mounting frame 2 is fixed on the upper surface of the base 1, and a cylindrical shell 4 is installed on the mounting frame 2, and the cylindrical shel...

Embodiment 2

[0061] A preparation method of organic fertilizer, comprising the following preparation steps:

[0062] S1, ingredients, weigh 3t of sludge, 5t of edible fungus residue, 2t of pig manure, and 1t of biochar raw materials, and mix them evenly to obtain a premix;

[0063] S2, premix treatment, drying the premix, adjusting the moisture content of the premix to 65%, adding 0.25t of thermophilic fermentation bacteria to obtain the preparation;

[0064] S3. Preparation of organic fertilizer. Pour the prepared material into the fermenter, ventilate at intervals, keep the stirring speed at 3 rpm, control the temperature in the fermenter at 80° C., and react for 24 hours to obtain the organic fertilizer.

Embodiment 3

[0066] A preparation method of organic fertilizer, comprising the following preparation steps:

[0067] S1, ingredients, weigh 4.5t of sludge, 7.5t of edible fungus residue, 2.5t of pig manure, and 1.5t of biochar raw materials, and mix them evenly to obtain a premix;

[0068] S2, premix treatment, drying the premix, adjusting the moisture content of the premix to 65%, adding 0.04t of thermophilic fermentation bacteria to obtain the preparation;

[0069] S3, preparation of organic fertilizer, pour the prepared material into the fermenter, ventilate at intervals, and keep the stirring speed at 3rpm, control the temperature in the fermenter at 80°C, and react for 24 hours to obtain the organic fertilizer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com