Pencil sharpener

A pencil sharpener and pen feeding technology, which is applied in the field of stationery, can solve the problems that pencils are easy to be sharpened by mistake and waste, and achieve the effects of easy popularization and use, convenient production and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The parts that are not described in detail in the text can be realized by conventional technical means.

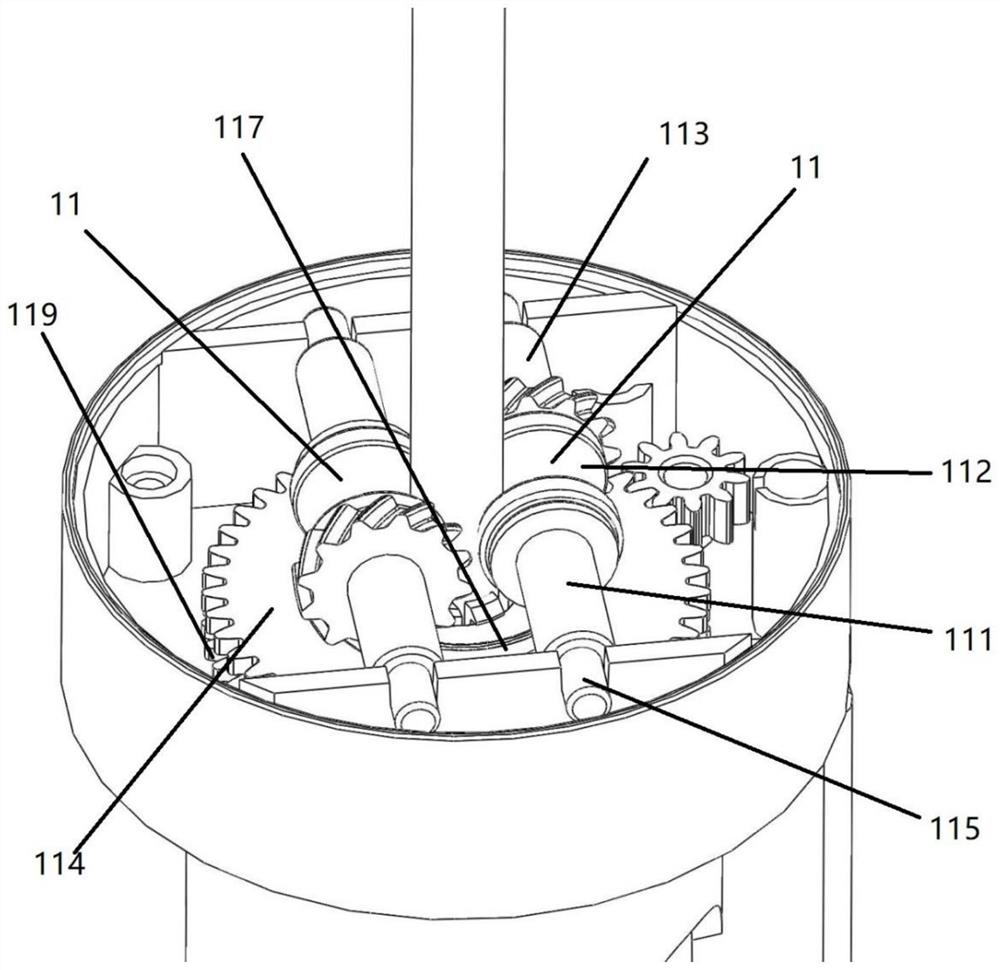

[0060] as 1 to Figure 31 As shown, a pencil sharpener includes an automatic pen feeding structure, a self-starting structure, a knife holder 3, a gear adjustment structure, a pen tip protection structure and a detachable pencil sharpening stand.

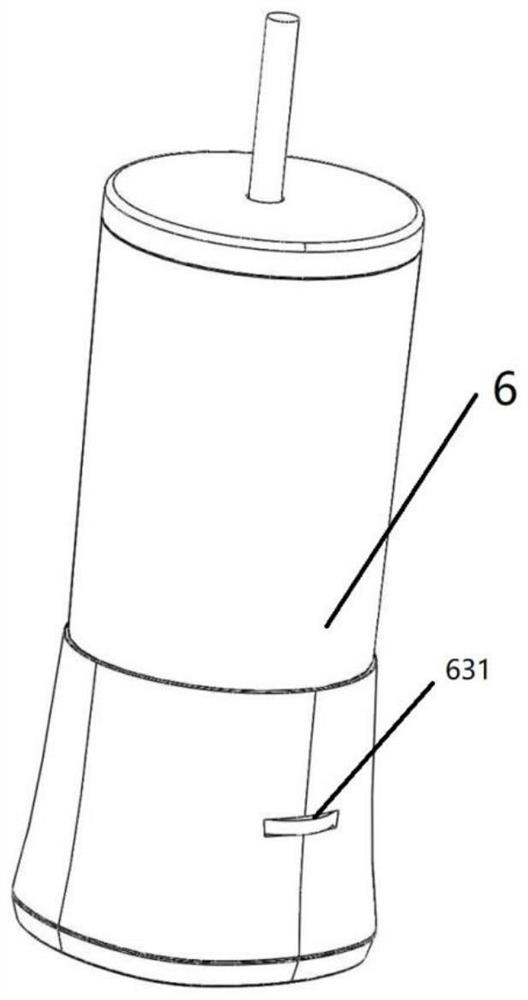

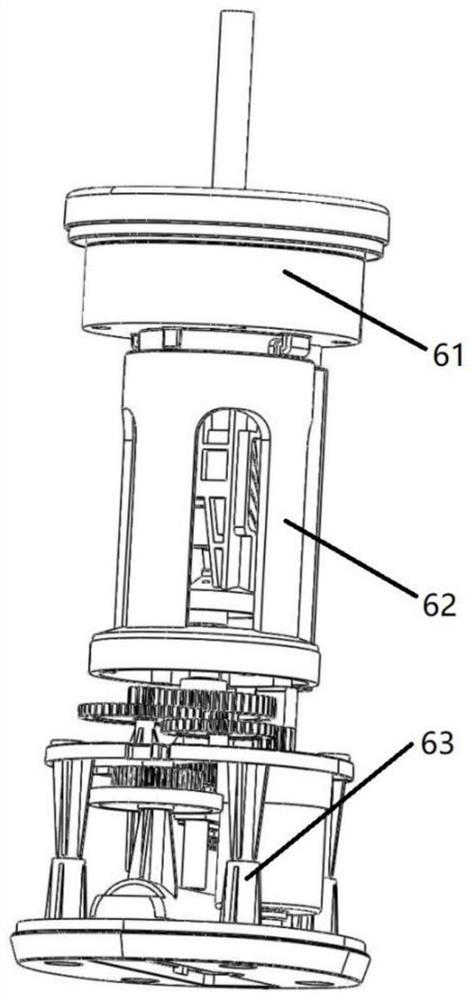

[0061] The detachable pencil sharpener includes an upper part 61, a middle part 62 and a lower part 63. The automatic pen feeding structure is set on the upper part 61, the tool rest 3 is set on the middle part 62, the gear adjustment structure is set on the lower part 63, and the self-starting structure and the pen tip protection structure run through the upper part 61. , middle part 62 and lower part 63. That is to say, the whole pencil sharpener is built by the detachable pencil sharpener stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com