Welding tool for steam turbine partition plate

A welding tool and steam turbine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, low efficiency, cumbersome and other problems, achieve convenient operation, convenient cutting, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

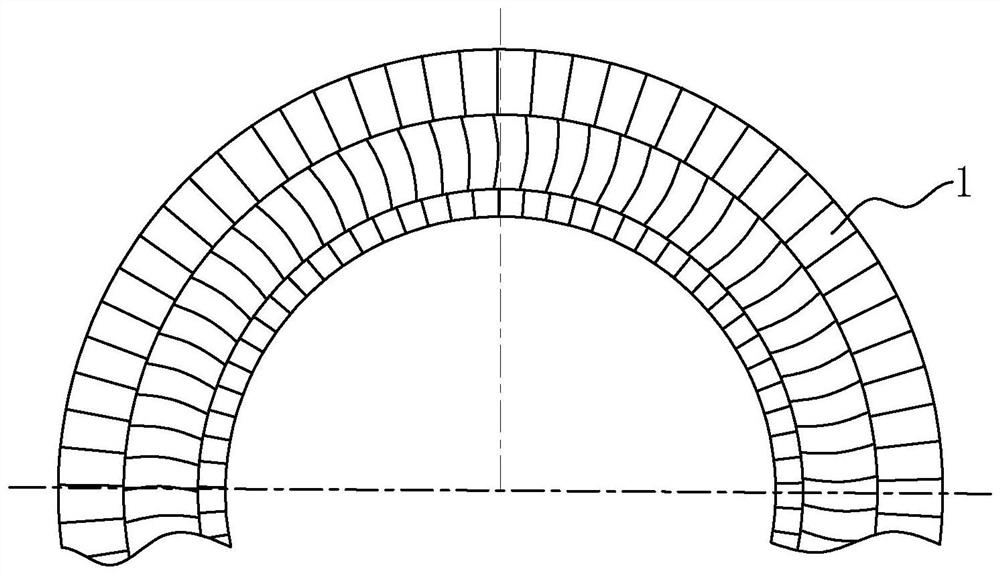

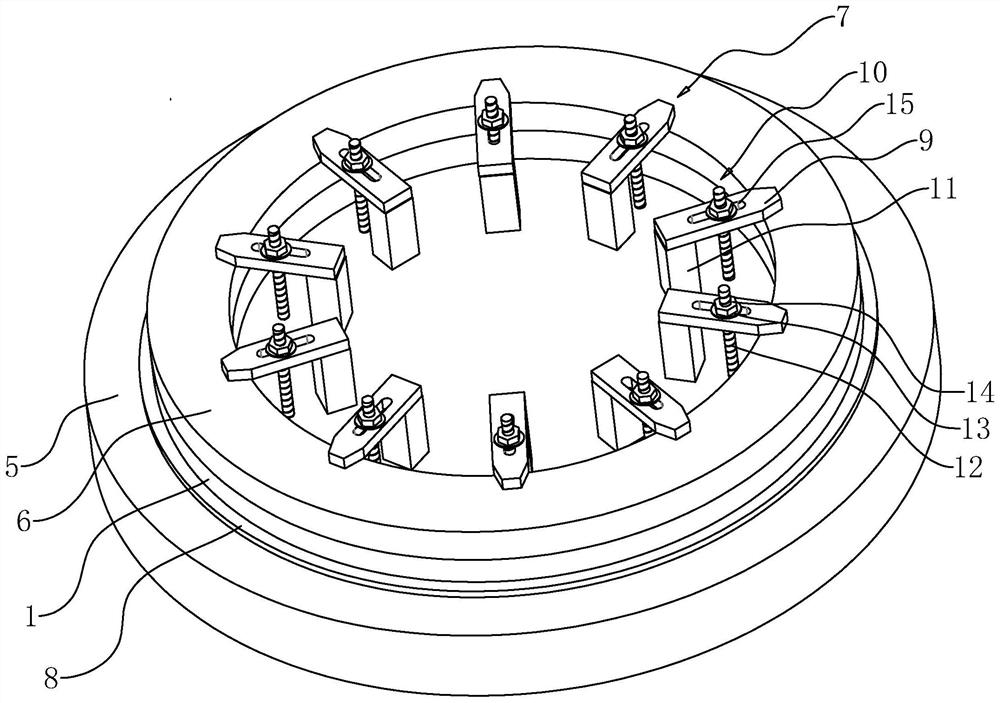

[0049] This application example discloses a welding tool for a steam turbine separator. Refer image 3 A welding tool for a steam turbine separator includes a carpet 5, a pressure ring 6, and a pressure assembly 7. The pressure assembly 7 is provided in a portion of the pressure ring 6 weeks. When the clip is fitted, the pressure ring 6 is paired by the pressure ring 6, and all the separator units 1 to be welded is held by the pressure ring 6 and the carotid 5 to be welded.

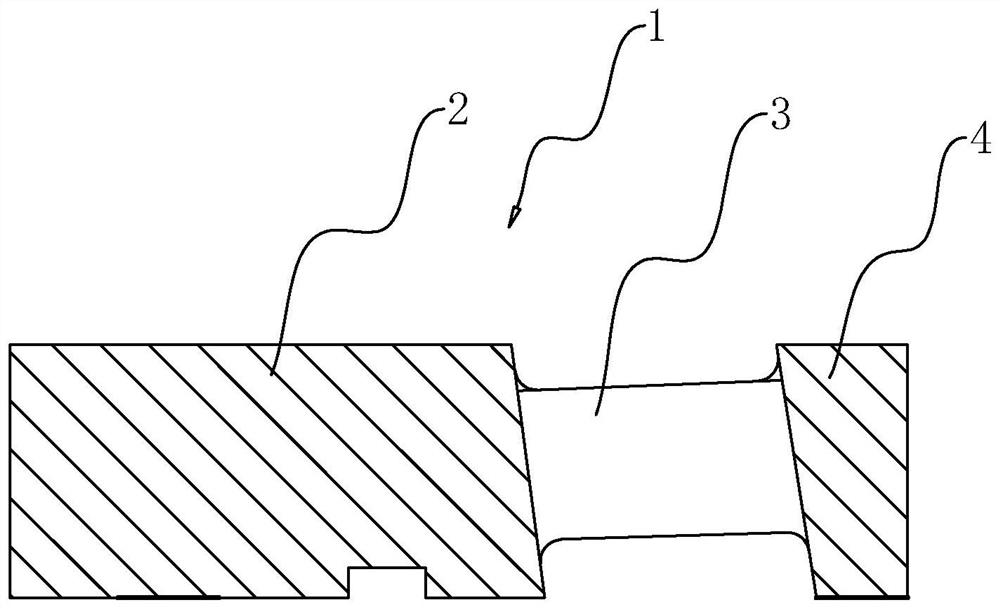

[0050] Specific, reference image 3 and Figure 4 The finished member 8 is provided on the fim 5, and the restricted part 8 is annular, and the housing for the separator unit 1 is placed. The pressure assembly 7 includes a straight pressure member 9, a lock member 10, and a support 11. The lock member 10 includes a screw 12 that is sleeve 13 and a thread to which the screw 12 is connected to the screw 12. The screw 12 is disposed in the vertical direction and is fixed to the end surface of the fetal 5. The screw...

Embodiment 2

[0060] Refer Figure 7 The difference between Example 2 and Embodiment 1 is that the diameter of the limit piece 8 is smaller than the outer loop diameter of the separator and is greater than the inner ring diameter of the partition. A groove for the fitting site 8 is opened on the separator unit 1.

[0061] At the assembled clip, the groove of the separator unit 1 is aligned with the limit seat member 8 and the groove sleeve is disposed to be placed on the belt 5. Then, all the separator units 1 is placed on the carpet 5 along the limit seat 8 to form a circular separator.

Embodiment 3

[0063] Refer Figure 8 The difference between Example 3 and Embodiment 2 is that the locking member 10 includes a fastener 14 and a screw 12 that is fixed to the upper end of the screw 12, and the tension 14 is a hexagonal prism. The screw 12 is threaded onto the fetal 5. When the clamp is assembled, the screw 12 can be rotated directly to move the elimination head 14 downward, so that the separator unit 1 is fixedly fixed by the diaphragm 6 and the fetal 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com