Machine tool screen-replacement-free gas filtering device

A filtering device and gas technology, which is applied to the field of machine tool-free screen-changing gas filtering devices, can solve problems such as blockage of filter screens, and achieve the effects of improving screen-changing and recoil efficiency, increasing filtering area, and prolonging filtering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

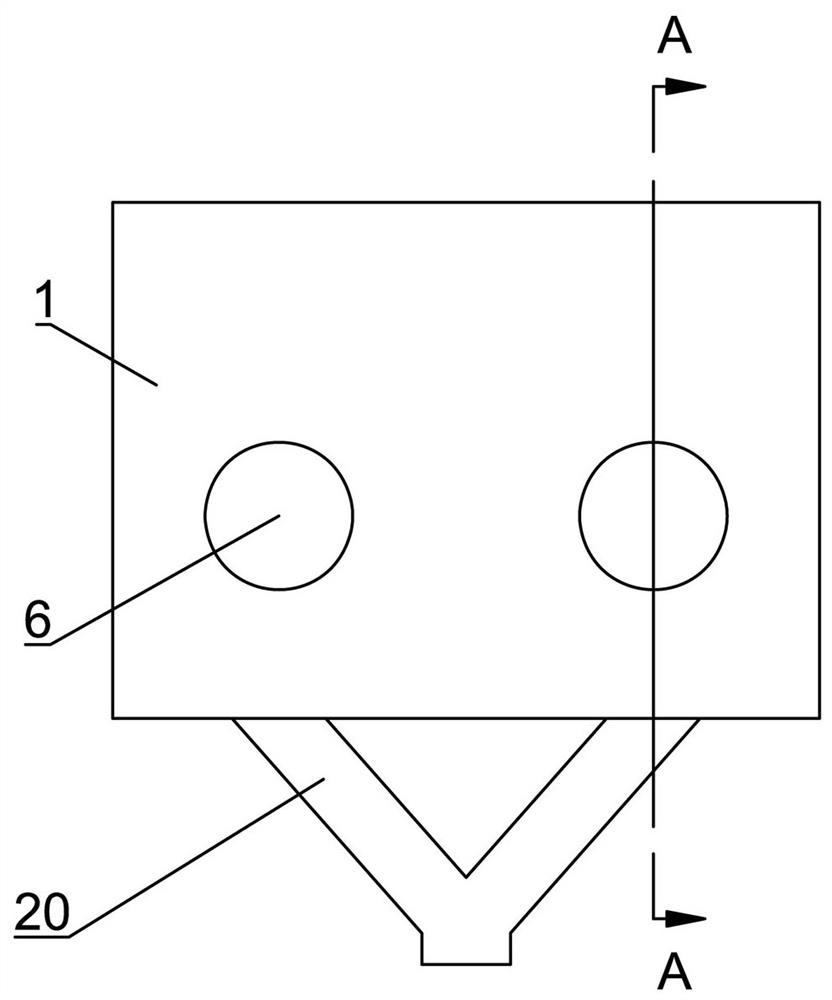

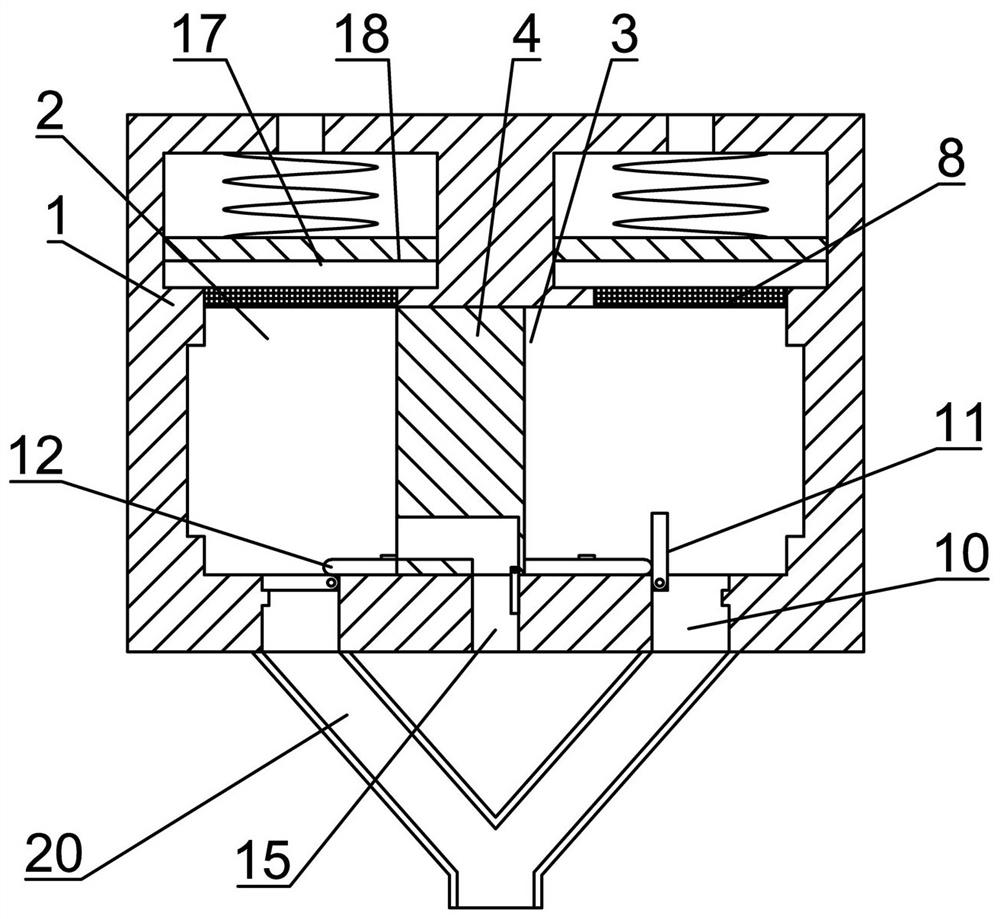

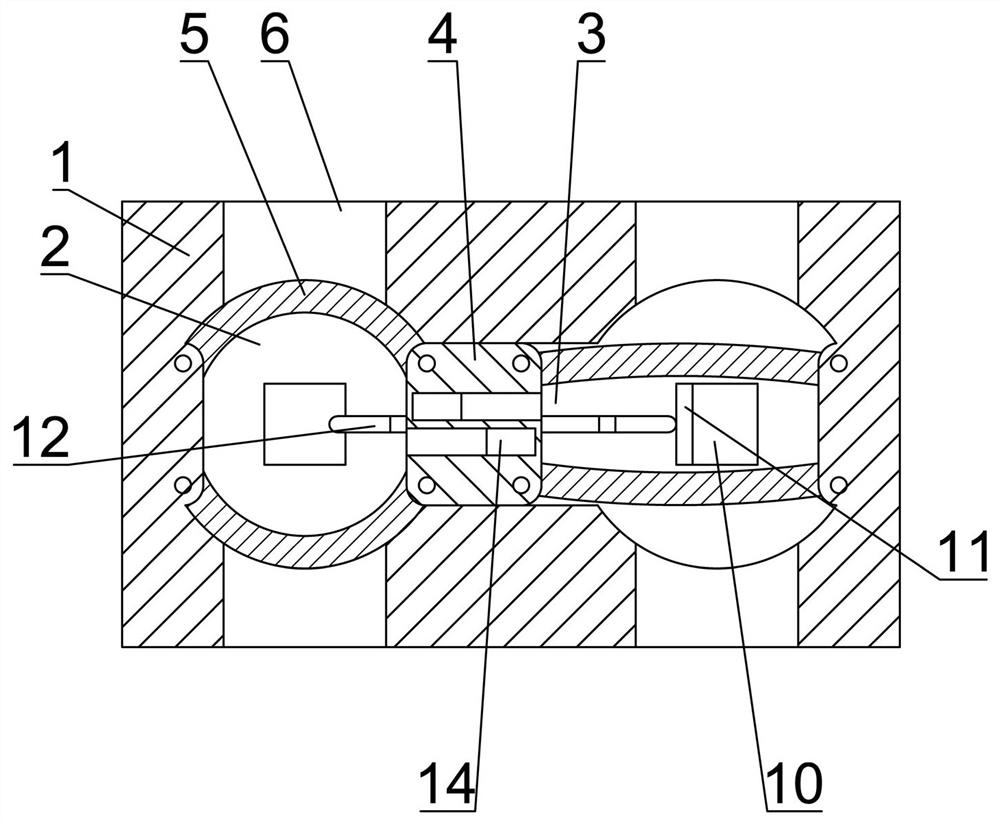

[0022] Depend on Figure 1 to 8 In addition, the present invention includes a rectangular housing 1, and a cavity 2 is opened on both sides of the housing 1, each cavity 2 is a cylindrical cavity of the axis is a vertical direction, each cavity 2 The front and rear sides are opened, and an air hole 6 in communication with the housing 1 is opened. The communication hole 3 in which the two cavity 2 is inserted in the casing 1, and there is a slider 4 in the through hole 3, and the slider 4 can be Sliding left and right and always in turn on both sides of the through hole 3, each of the cavity 2 has an arcuate plate 5, and all the arcuate plate 5 axes are toward the inner side of the corresponding cavity 2 and each curved panel. 5 Part 2 seals the cavity 2, and the arc plate 5 is hinged on the slider 4 and the cavity 2, respectively, and when the slider 4 slides to any end of the through hole 3, the corresponding end two arc 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com